Introduction

When sourcing custom iron castings from China, there are a number of factors that need to be considered to control costs.

In this blog post, we will discuss some of the key cost considerations when sourcing iron castings from Chinese suppliers. By understanding these factors, you can get a full picture of the cost structures prior to sourcing to ensure you get the best value for your money and avoid any surprises.

Let’s get started!

Mold Costs

The first cost structure is the mold. Custom iron castings, whether for prototyping or mass production, are an essential part of the process of opening a mold according to the customer’s specific needs.

The cost of the mold includes the cost of design, materials, and machining.

Iron casting suppliers are generally equipped with their own design team to design 3D drawings according to the customer’s needs. If the customer has his own drawings, it can save design time and move to the next stage faster and more efficiently.

Depending on the size of the product and the number of orders, the material of the mold is divided into aluminum mold, wood mold and foam mold.

Depending on the complexity of the product, custom sand cores are also required. The cost of a mold with a sand core will be about 1.5 times more expensive than the cost of a mold without a sand core.

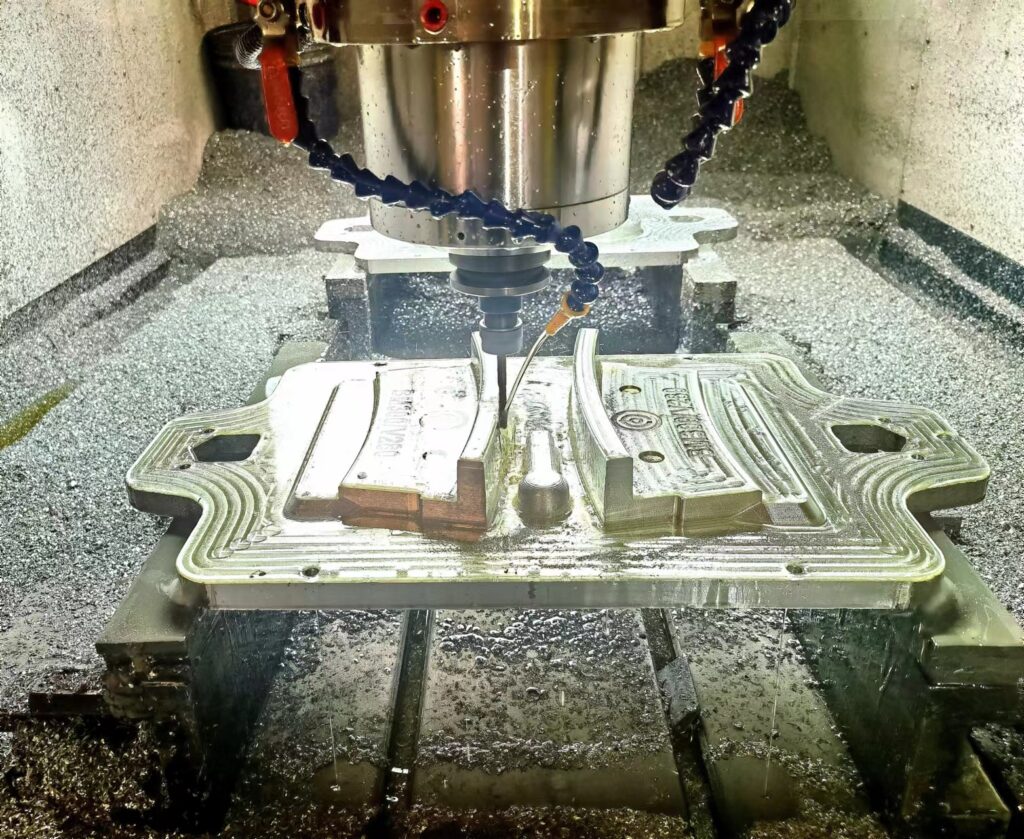

The last step is the machining of the mold. After the material is set, the template material is machined, polished and tested according to the 3D drawing previously designed.

The cost of machining depends on the size and complexity of the product and can take up a significant portion of the overall mold cost.

Sampling Costs

The second cost component is sampling. Before mass production, samples must be made and tested to ensure that the product meets customer requirements.

Small pieces of iron castings for sampling, generally within 5kg, are normally not required for sampling production costs, but if the product is large in weight and volume, tens of kilograms for one cast iron part, or even hundreds of kilograms, then sample costs are required to be provided.

In addition, the cost of sending samples is required to be taken into account.

The way of sending samples is generally divided into air and sea, according to the customer’s time limit to choose the right way of sending samples.

Air shipping is faster and takes less time, but it is very expensive. If the weight of the sample is large, choosing sea freight is a good way to control the cost, when you can plan your purchase well in advance. After all, there are delays in shipping by sea, especially during global epidemics.

Production Costs

The third cost component is the cost of production.

In terms of production costs, the main factor to consider is labor.

China has a large population base and relatively low wages, which gives it an advantage in labor-intensive industries such as cast iron.

But labor costs in China have also been rising year after year in recent years, and this must be taken into account when sourcing iron castings from China.

Another cost component is the cost of materials.

The price of raw materials such as pig iron and scrap can vary seasonally, which affects the costs associated with the production of iron castings in China.

For example, if you purchase iron castings during a period of high raw material prices in China, then your total production costs may be higher than expected.

There are also alloying elements that are added that can affect the cost of the material.

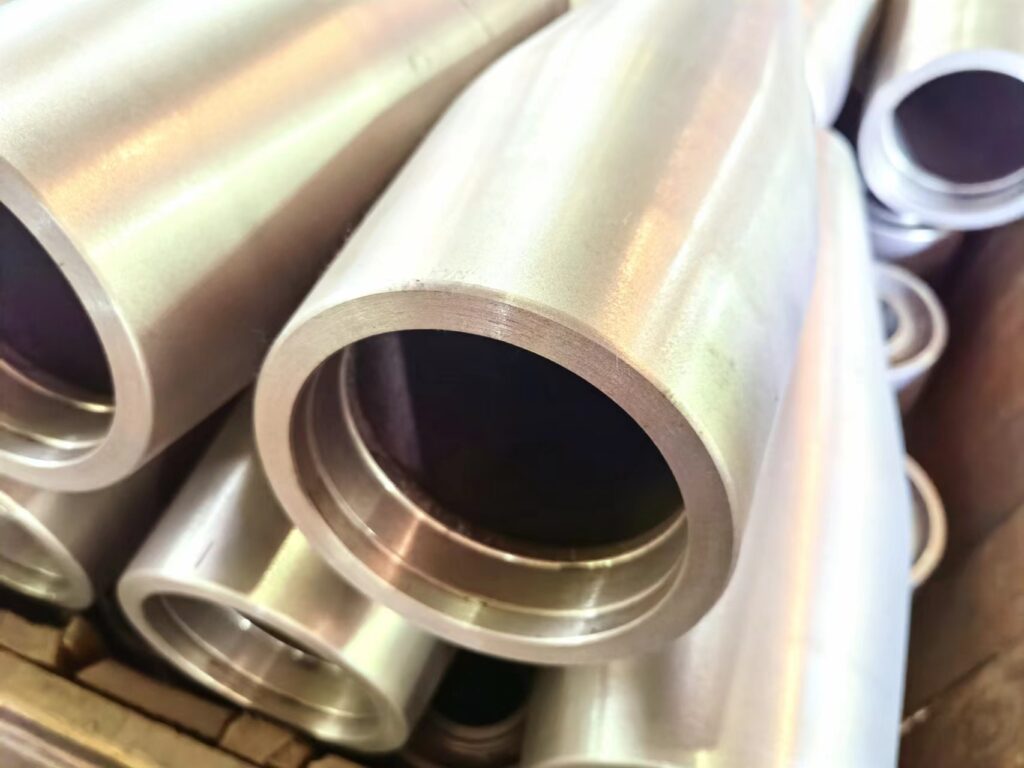

If your iron castings require machining, then machining costs also need to be considered.

If your preferred casting supplier is also equipped with machining equipment and can also provide you with machining services, then you can save a considerable amount of outsourcing costs.

Inspection costs should not be overlooked when sourcing iron castings from China.

Quality assurance is important in any supply chain and additional costs associated with quality control measures, such as inspection and sample testing by an independent third-party agency before the goods are shipped to the customer, must be considered.

By investing in a quality assurance program, buyers can ensure that their products meet all quality requirements at a reasonable cost.

There are also additional costs associated with producing iron castings in China, such as the cost of packaging, shipping, and storage, which should also be factored into your budget for any project involving a Chinese iron casting supplier.

All of these factors must be considered prior to entering into an agreement with a Chinese supplier.

Other factors that are easier to overlook include taxes, administrative costs, depreciation of equipment, environmental protection costs and other external costs required by the plant.

All of these costs will of course be reflected in the price list quoted to you by the supplier.

Trade Costs

The price quoted by the factory to the customer is usually ex-works (EXW), while goods exported from China require Free on Board (FOB) or Cost Insurance and Freight (CIF).

This part is done by traders who have the right to import and export. A professional trading company has the experience and knowledge to ensure a smooth export process.

In addition to transportation costs, there are other factors such as document preparation fees, customs clearance fees, bank charges, etc. These factors add up to the total trade cost.

It is also important to consider currency exchange rates when sourcing from China, as prices may fluctuate due to foreign currency fluctuations.

Converting the customer’s local currency into US dollars or other forms of currency at the time of payment must be communicated to the supplier in advance.

Currency conversions incur bank charges.

Be sure to check the current exchange rate and use this information when budgeting for your iron casting purchase.

Shipping Costs

Sea freight costs include sea freight, marine insurance, port charges, etc.

Costs depend on the volume of the shipment, the destination port, the type of shipment, and the ocean carrier selected.

Depending on the volume of cargo, it is decided whether the container container used is 20 feet or 40 feet, and whether to go full container (FCL) or less than container load (LCL).

Port charges include LSS, AMS, THC, booking, loading and unloading, customs clearance, electric release, paperwork processing and a series of other charges.

The important thing to remember is that imports from China are subject to duties and taxes. Duties and taxes include VAT, excise duties, import duties and other taxes.

These can vary greatly depending on the customer’s country’s trade agreement with China.

So what you need to do is please check with your local customs office to determine which duties and taxes, if any, apply to the items you plan to import.

After the goods arrive at the port of destination, they will also have to be cleared and shipped. You need to consider the costs associated with customs clearance and domestic transportation.

You can ask your local freight forwarder for these and they will make the arrangements.

Opportunity Costs

Besides the visible external costs mentioned above, finally, there are internal costs that need to be taken into account. For example, the cost of time to find and compare suppliers, the cost of communication with suppliers, etc.

These unseen costs are sometimes more important than the visible costs.

A quality iron casting supplier not only can provide quality products and services, but also can always think about the interests of customers in the communication with them to achieve win-win situation.

Low price, extremely cost advantageous supplier for the buyer is very attractive, it is easy to be tempted. But don’t forget that the buyer’s goal is to get high quality products and services.

Quality issues, delivery delays and other problems are likely to be a risk associated with low prices.

If problems arise in the process of ordering from China, they can not only cause huge financial losses, but also disrupt production schedules or delay the supply chain.

Therefore, it is necessary for buyers to choose a reliable supplier before placing an order.

Considering all these cost factors, it is important to consult an expert who can help manage the risks and guide you through the procurement process from start to finish.

Castimoo is a supplier specializing in the design and production of gray cast iron as well as ductile iron, and has been deeply involved in this field for 30 years.

We have provided no less than 300 products and solutions to our domestic and international customers. Our quality products and services have been well received by our customers both at home and abroad.

If you have a need to purchase iron castings, I think we will be able to help you.

Conclusion

In conclusion, there may be many cost factors to consider when sourcing iron castings from China, including mold costs, sampling costs, production costs, trade costs, shipping costs, and opportunity costs.

It is important to fully understand these different factors before deciding where to source your product from.

With a thorough understanding of all of these structures, with careful planning and preparation, you will be able to make an informed choice for sourcing iron castings from China, ensuring you get the best value for your money for your next project.

Happy sourcing!

One Response