Gray Iron and Ductile Iron Castings

30 Years Experience

All you need to do is tell us what you need, and our R&D team

led by university professors will provide you with a professional

OEM&ODM service from design to finished cast iron processing.

Successful Customized Projects

We customize gray iron castings and ductile iron castings with consistent quality and reasonable price. A full range of solutions to meet your needs.

Alternator Cover

Gray Iron 250 (35A)

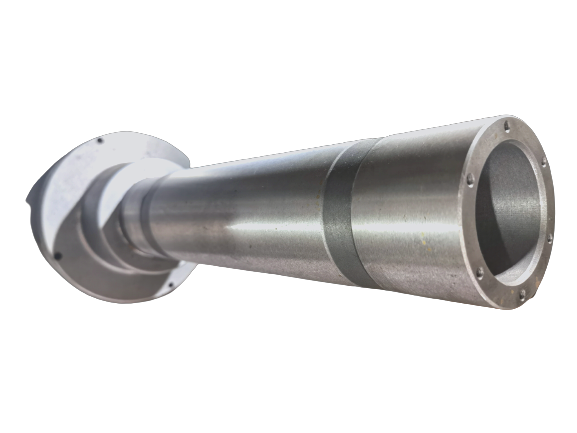

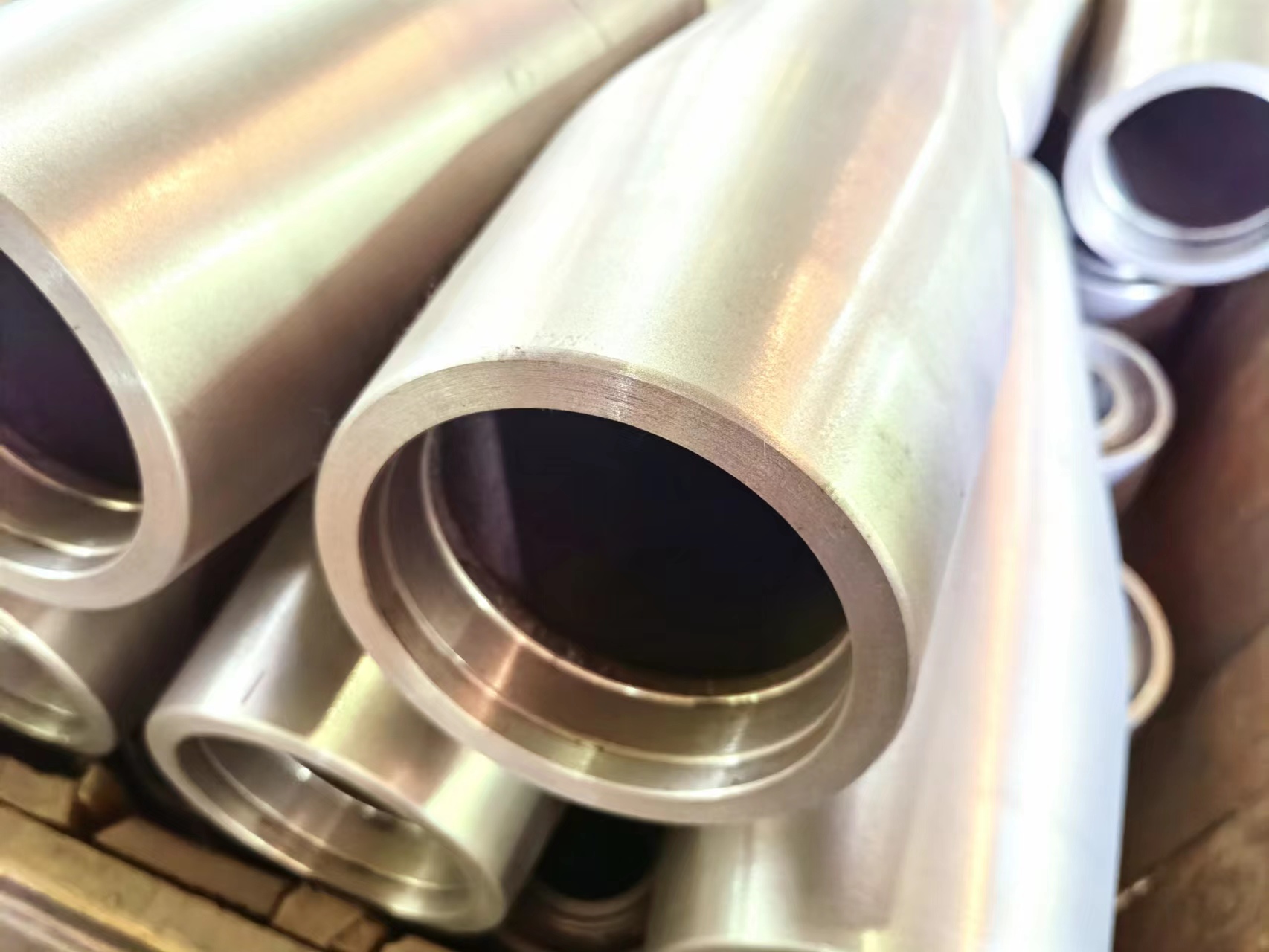

Motor bushing

Gray Iron 250 (35A)

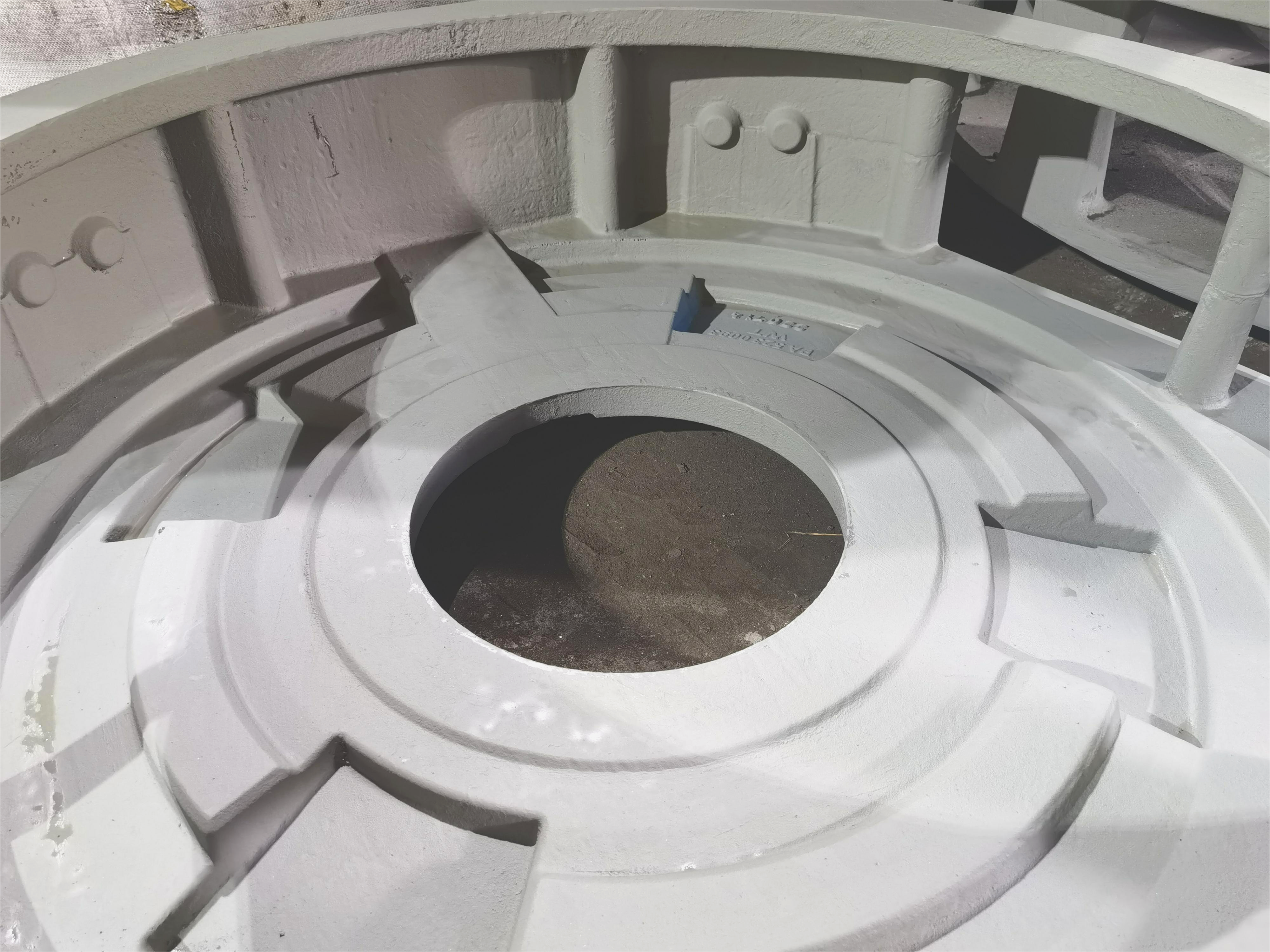

Generator housing

Gray Iron 250 (35A)

Rectifier support base

Ductile lron 400-15 (65-45-12)

Drive Tray

Ductile lron 400-15 (65-45-12)

Roller Sheave

Ductile lron 600-3 (80-60-03)

World Class Partnership

The No.1 reason you should buy from us is because they choose us too.

Sand Casting Services

2 green sand automatic molding lines and 1 resin sand molding line to provide you with the most complete casting service.

Green Sand Casting

We control the quality of the sand by 4 parameters. They are the effective bentonite content, compactability, wet compressive strength and moisture control.

Resin Sand Casting

It has high thermal stability and low permeability and is usually used for large precision castings with complex shapes. Its advantages include good surface finish, excellent dimensional accuracy and repeatability.

Why Choose Castimoo

3D Design

1, Provide professional pattern design services according to your needs.

2, Just 10 days from designing the pattern to producing the sample, to ensure you can get the sample for evaluation in the shortest time.

3, The team led by university professors to design a reasonable pouring system for ductile iron, which means you no longer worry about shrinkage.

Ingredient Determination

1, Equipped with independent ingredient determination laboratory.

2, Has a metallographic tester, hardness tester, spectral analyzer, etc.

3, Daily record data to ensure stable composition and hardness, thus guaranteeing quality.

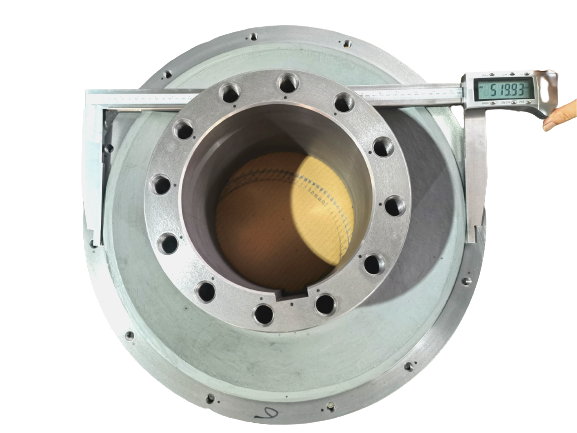

Mechanical Processing

1, Professional machining team with 20+ years of experience.

2, With 10+ NC and CNC machines, ensure on-time delivery.

3, Quality inspection management system, strict control of processing accuracy.

One-stop Professional Solution

ISO9001 quality management system, strict control of each step of iron casting production.

OEM&ODM 3D Drafting

Pattern Making

Ingredient Determination

Casting Production

Mechanical Processing

Tolerance Testing

Anti-rust Treatment

Packing and Shipping

Real Foundry Videos

We have 2 casting lines and 12 cnc machines to ensure that any of your custom needs are met.

We have good production capacity with 2 working shifts, to ensure that we can shorten the delivery days and help you sell faster in your local market.

Our Happy Clients

Frequently Asked Questions

Most frequent questions and answers

Q: What types of iron castings can your company manufacture?

A: Our company can manufacture a wide range of iron castings, including gray iron castings, ductile iron castings, and alloy iron castings, among others. Our products can be customized to meet your specific requirements.

Q: What is the process for ordering iron castings from your company?

A: To order iron castings from our company, you can contact us via email or phone to discuss your requirements. We will provide you with a quote based on the specifications of your order. Once you have approved the quote and provided payment, we will begin manufacturing your castings. We will keep you updated throughout the process and provide you with a delivery date.

Q: Can you provide custom designs for iron castings?

A: Yes, our company can work with you to create custom designs for iron castings. We have a team of experienced designers who can work with you to create a design that meets your specific needs and requirements.

Q: How long does it take for your company to manufacture iron castings?

A: The manufacturing time for iron castings can vary depending on the complexity and size of the order. We will provide you with an estimated manufacturing time when we provide you with a quote.

Q: How do you ensure the quality of your iron castings?

A: We have a strict quality control process in place that includes regular inspections and testing throughout the manufacturing process. Our team of experienced professionals also ensures that all castings meet industry standards and customer requirements.

Q: What is the pricing for your iron castings?

A: The pricing for our iron castings depends on several factors, including the type and size of the casting, the quantity ordered, and the complexity of the manufacturing process. We will provide you with a quote based on your specific requirements.

Contact us for Free design solutions

Please rest assured. Your information will be kept strictly confidential.