Introduction

In the world of iron casting, precision and efficiency are paramount. Whether you’re in China, the USA, Japan, Europe, or anywhere else in the world, the success of your project often hinges on the capabilities of your iron casting manufacturer.

One crucial aspect to consider when selecting the right manufacturer is their production capacity. But how do you determine what the average production capacity of an iron casting manufacturer is? In this comprehensive guide, we’ll walk you through the process, helping you make informed decisions that can significantly impact your project’s success.

Why Production Capacity Matters

Before diving into the specifics of assessing production capacity, it’s important to understand why it matters. The production capacity of an iron casting manufacturer can have a profound effect on several key aspects of your project:

- Timelines

Production capacity directly affects the timeline of your project. Manufacturers with higher production capacities can often complete orders more quickly, helping you meet your deadlines and project milestones. On the other hand, a manufacturer with limited capacity may cause delays that could disrupt your entire schedule. - Costs

Efficient, high-capacity manufacturers can often offer more competitive pricing due to economies of scale. This means that you can potentially save money by choosing a manufacturer with the right production capacity for your needs. - Quality

While quantity is important, quality should never be compromised. A manufacturer’s production capacity should align with their ability to maintain stringent quality control standards. Choosing a manufacturer with the right balance between quantity and quality is crucial.

Now that we’ve established why production capacity is critical, let’s explore the factors that influence it.

Factors Affecting Production Capacity

Several key factors influence the production capacity of an iron casting manufacturer:

- Machinery and Equipment

Modern machinery and equipment are at the heart of efficient iron casting. Manufacturers with state-of-the-art equipment can often handle larger volumes and more complex projects. When assessing production capacity, inquire about the manufacturer’s machinery, its age, and its capabilities. - Skilled Workforce

A skilled workforce is essential for maximizing production capacity. Experienced foundry workers can operate machinery efficiently and minimize downtime. Consider the manufacturer’s training and certification programs for their employees. - Facility Size and Layout

The physical size and layout of the manufacturing facility play a crucial role in determining capacity. A larger facility with an optimized layout can accommodate more equipment and workers, leading to higher production volumes. During facility tours, pay attention to layout efficiency and available space. - Production Processes

Different casting methods, such as sand casting, investment casting, and die casting, have varying production capacities. The chosen method can significantly impact the manufacturer’s overall output. Discuss the casting method with the manufacturer and its implications for your project. - Technological Advancements

Advancements in technology, such as automation and digitalization, can enhance production efficiency. Inquire about the manufacturer’s adoption of technology and how it impacts their production capacity.

Now that you’re aware of the key factors, let’s delve into the methods for assessing production capacity.

Methods for Assessing Production Capacity

Assessing the production capacity of an iron casting manufacturer involves a combination of research, communication, and on-site evaluation. Here are practical methods to help you make an informed assessment:

- Requesting Information

Start by requesting detailed information from the manufacturer. This includes:

Capacity Data: Ask for statistics on their daily, weekly, or monthly production capacity.

Lead Times: Inquire about typical lead times for projects of similar scope to yours.

Certifications: Check for industry certifications, which often reflect a manufacturer’s commitment to quality and efficiency.

- On-Site Visits

Arrange an on-site visit to the manufacturer’s facility if possible. During the visit:

Observe Operations: Witness the production process firsthand to gauge efficiency.

Talk to Employees: Interact with the workforce to understand their experience and the company’s commitment to training and skill development.

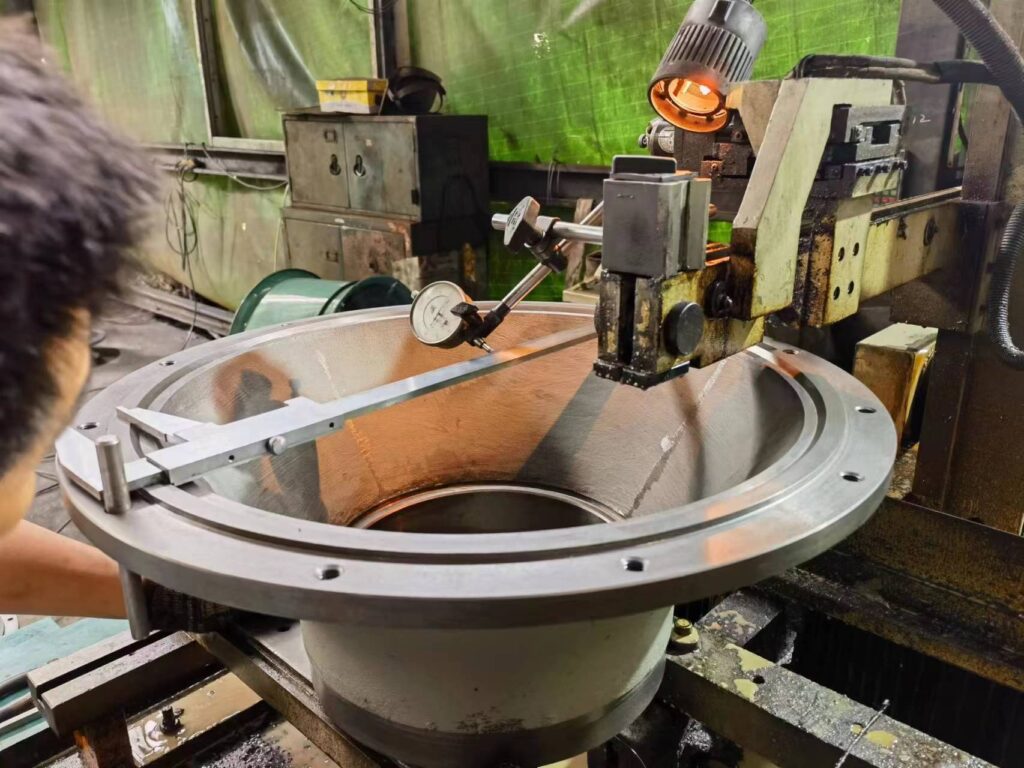

Evaluate Equipment: Assess the condition and capabilities of the machinery and equipment in use.

Review Facility Layout: Note the organization and layout of the facility to gauge space utilization.

- References and Past Projects

Gather references and case studies from the manufacturer. Contact past clients to learn about their experiences. Relevant questions to ask include:

Timeliness: Did the manufacturer meet project deadlines?

Quality: Were the produced castings of the expected quality?

Communication: How effective was the communication between the client and the manufacturer?

Case Studies

To illustrate the practical application of these methods, let’s explore a couple of case studies where Castimoo successfully determined and met the production capacity needs of its clients.

Case Study 1: High-Volume Automotive Parts

A leading automotive manufacturer required a reliable supplier for high-volume iron castings used in engine components. Castimoo conducted a thorough assessment, including on-site visits and equipment evaluations. By aligning their production capacity with the client’s needs, Castimoo delivered consistent quality while meeting high demand. The result? Reduced production costs for the client and improved production efficiency.

Case Study 2: Complex Architectural Castings

An architectural firm needed intricate iron castings for a unique building project. Castimoo not only provided the necessary production capacity but also demonstrated their expertise in precision casting techniques. Through collaborative communication and a focus on quality, Castimoo exceeded the client’s expectations, resulting in a successful architectural marvel.

Quality vs. Quantity: Finding the Right Balance

While assessing production capacity, it’s crucial to strike the right balance between quantity and quality. Here’s how Castimoo maintains high-quality standards while meeting production demands:

Stringent Quality Control: Castimoo adheres to strict quality control processes at every stage of production.

Skilled Workforce: A highly skilled and trained workforce ensures that quality is never compromised, even with high production volumes.

Continuous Improvement: Castimoo invests in continuous improvement initiatives to enhance efficiency and reduce defects.

Custom Solutions: Tailored production strategies are employed to meet specific project requirements while maintaining quality benchmarks.

Conclusion

In the intricate world of iron casting, understanding and assessing production capacity are vital steps toward a successful project. The right iron casting manufacturer, with the appropriate production capacity, can make all the difference in achieving your project goals on time and within budget. Castimoo’s commitment to efficiency, quality, and innovation positions it as a reliable partner for all your iron casting needs.

Make informed decisions, ask the right questions, and remember that quality should never be compromised for quantity. By following the methods outlined in this guide, you can unlock the efficiency you need for your next iron casting project.

Call to Action (CTA)

Ready to explore how Castimoo can meet your iron casting needs? Contact us today for a consultation or a quote. Let us help you bring your iron casting projects to life with precision, efficiency, and quality.