Instruction

Cast iron is a metal alloy composed of pig iron, carbon and silicon. It has a high melting point and can be used for a variety of applications, such as construction and automotive manufacturing.

Cast iron is an extremely important material in many construction and industrial projects. Its high strength, low cost and ease of production make it a popular choice for many applications.

However, the quality of cast iron can only be seen in the microstructure of its components. The microstructure affects the overall quality of the finished cast iron product and can determine how good it is.

To ensure the quality of cast iron products, it is important to test the microstructure of cast iron.

In this blog post, we will discuss different methods of testing the microstructure of cast iron and how to interpret the results.

Microstructure of Cast Iron

The microstructure of cast iron refers mainly to the internal grains, graphite grains, and other substances present in the material.

The grain size of cast iron is an important factor in its strength and ductility. Smaller grains will produce higher strength, while larger grains will produce greater ductility.

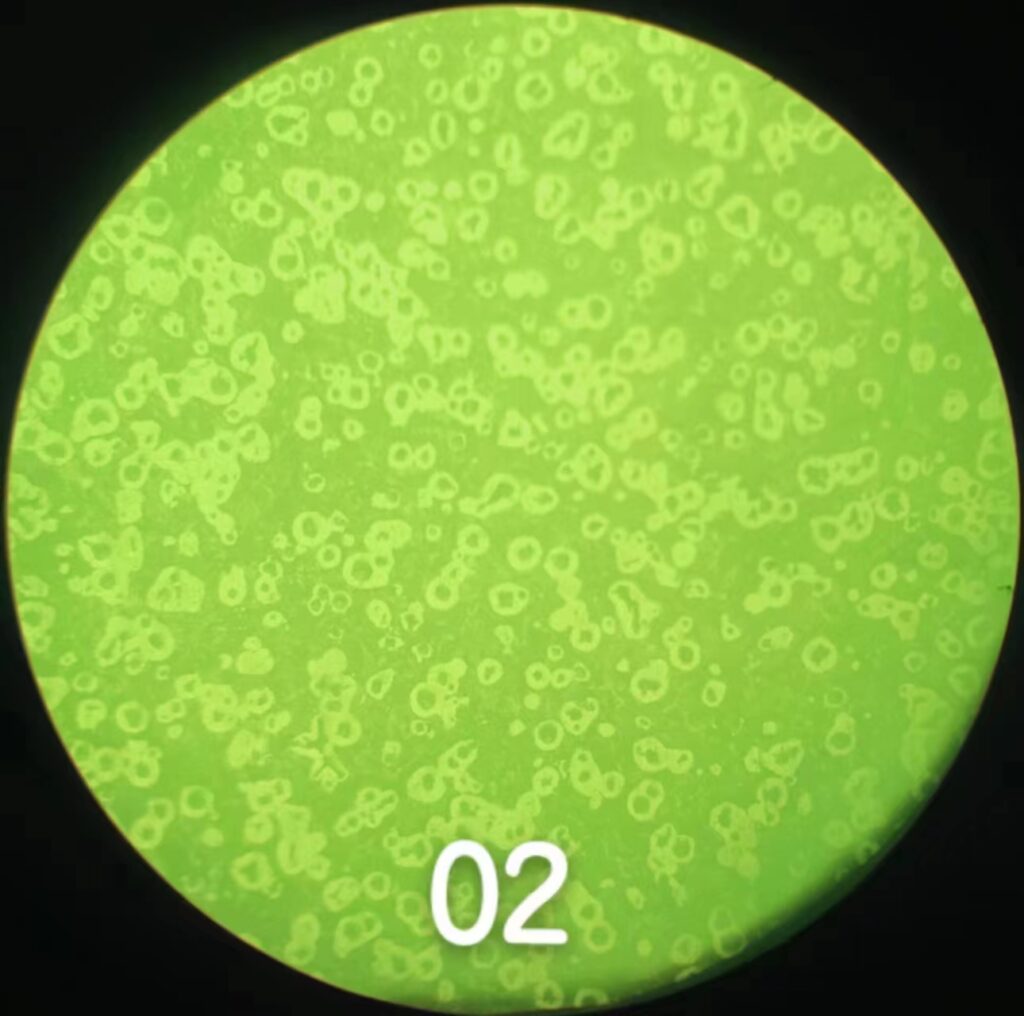

The shape and size of the graphite grains directly affect the strength, hardness and wear resistance of cast iron. The shape and size of the graphite can be determined by looking at the microstructure using a microscope. Well formed graphite grains will create a stronger material than those that are poorly formed.

Other substances present in the material, such as pearlite and ferrite. These substances contribute to the strength, hardness and wear resistance of cast iron. Depending on the percentage of pearlite and ferrite present in the microstructure, these materials can affect the overall quality.

Methods of Detecting Microstructure

1. Optical microscope

One way to test the microstructure is through the use of an optical microscope. This involves looking at the specimen under an optical microscope at a high magnification (up to 1000x).

The optical microscope works by focusing light onto the specimen and magnifying this image for observation through the eyepiece.

Through careful observation, microstructural features such as carbide morphology, the presence of graphite in gray cast iron, and grain size and type can be identified.

The optical microscope enables us to determine the size and shape of the grains, as well as the inclusions in the iron casting.

Depending on the application, the need for different grain sizes and shapes can be easily determined by examining the sample under an optical microscope.

2. Scanning Electron Microscopy

Another way to test the microstructure of cast iron is through the use of a scanning electron microscope (SEM). This is a powerful tool that allows us to see microscopic details at very high magnifications (up to 50,000x).

Scanning electron microscopy provides a more detailed examination of the microstructure, allowing us to see individual grains and inclusions.

This can be used to determine how well the individual grains are bonded together and whether there are any defects in the iron casting.

SEM uses a focused beam of electrons to scan the surface of the sample. The electrons interact with the atoms in the sample and produce images that can be used to diagnose defects in the microstructure.

The process begins with the sample being prepared for inspection, which involves cleaning, polishing, and then applying a thin layer of gold or platinum. Once the sample has been prepared, it can be placed in an electron microscope for examination.

The SEM produces high-resolution images that provide detailed information about the microstructure of the cast iron. By examining these images, we can identify any signs of microstructural defects such as porosity, segregation, etc.

This method is fast and non-destructive and can be used to check the quality of cast iron parts before they are put into service. It is also useful for troubleshooting problems or investigating the cause of failures in existing components.

3. Metal microscopy

Metallographic observation using a metal microscope is another method that can be used to test the microstructure of cast iron. It is commonly known as the metallographic method.

This involves taking a sample of the casting material and grinding it into a very thin sheet. The specimen is then placed on a glass sheet and examined under a microscope.

By looking at the different grain sizes, shapes and orientations present in the specimen, the microstructure of the metal can be observed and analyzed.

Using this test method provides an understanding of how the metal is formed during the casting process. This information is very useful for analysis and problem solving.

When a part fails, metallography can be used to determine the cause and help make improvements.

In addition, metallographic testing is useful for determining the strength of casting materials.

In order to improve the strength of cast iron, different heat treatments are often applied to it. Metallographic analysis allows engineers to measure the success of these treatments.

This information can then be used to optimize future treatments and improve the performance of the cast iron.

It is important to note that metal microscopy is only suitable for specimens that are thin enough for light to pass through them. If the specimen is too thick, it will not be possible to accurately observe the microstructure.

In addition, certain areas of the sample may need to be etched to obtain a clear view. Metal microscopy allows us to determine the grain size, shape, distribution, orientation and other properties of cast iron.

The metal microscope is a useful tool for examining the microstructure of cast iron. It provides insight into how the material responds to different casting processes and heat treatments, which can be used to optimize production, troubleshoot and improve performance.

Conclusion

Overall, these three methods are most commonly used to test the microstructure of cast iron.

By examining a sample with an optical microscope, scanning electron microscope or metal microscope, we can determine the quality of the iron casting and ensure that it meets all specifications.

By understanding the microstructure, we can ensure the quality and performance of cast iron parts before they are put into service.

If you are looking at the Chinese market and want to source iron castings from China to bring revenue to your project, remember to have your iron casting supplier provide you with a microstructure test report on your iron castings during the sample testing, and mass production phase. This is a very critical part of guaranteeing the quality of your iron casting products.

We are Castimoo, specializing in the design and production of iron castings. We have an independent laboratory, equipped with perfect quality testing instruments and quality control system.

We issue professional test reports on material, structure and hardness to provide you with high quality gray iron and ductile iron products and bring greater benefits to your projects.

Welcome to contact us now!