Introduction

Iron castings are a popular choice for manufacturing due to their strength, durability, and versatility. They can be found in a variety of industries, including automotive, construction, and manufacturing.

However, not all iron castings are created equal. Customizing and personalizing iron castings offers a range of benefits that can make them even more valuable for your specific needs.

Here are just a few of the benefits of customizing and personalizing with iron castings:

1. Tailored to Your Exact Specifications

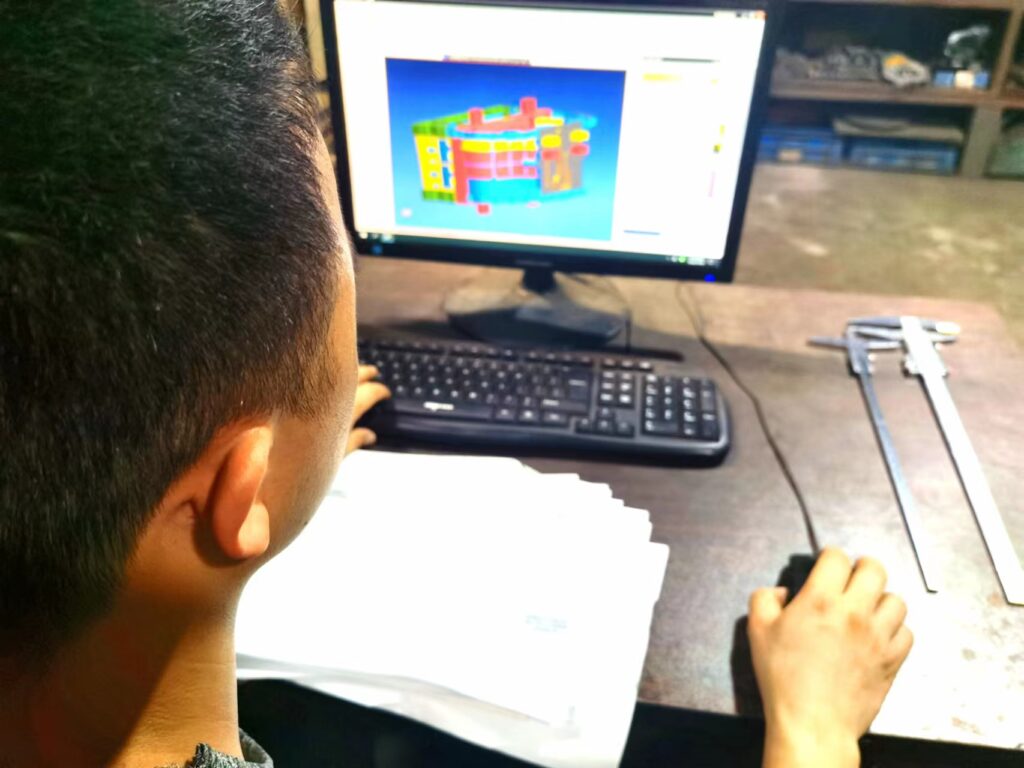

When you work with a manufacturer to customize and personalize your iron castings, you have the ability to tailor them to your exact specifications. This means you can choose the size, shape, and design that best fits your needs. By doing so, you can ensure that your iron castings will work seamlessly with your existing equipment, reducing the likelihood of errors or accidents.

For example, if you’re manufacturing a specialized piece of machinery that requires a specific shape of iron casting, customization allows you to produce a casting that fits perfectly into the design, without requiring additional modifications or workarounds. This can lead to better overall functionality and a more streamlined manufacturing process.

2. Improved Quality and Performance

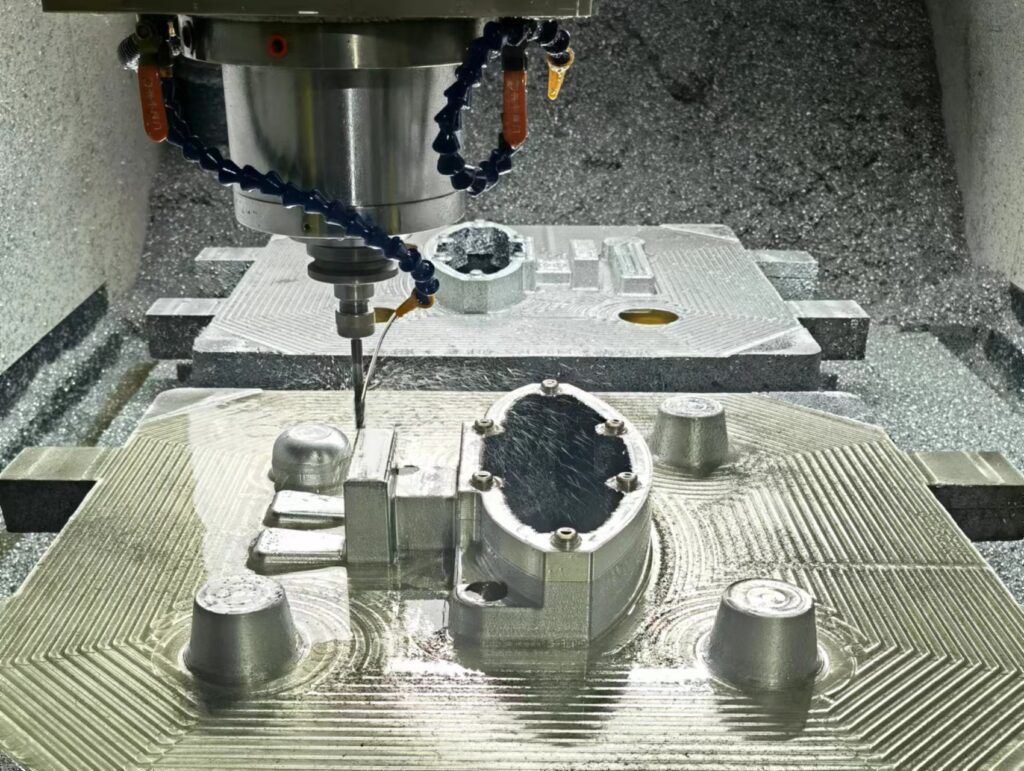

Customizing and personalizing your iron castings can also lead to improved quality and performance. By working closely with your manufacturer to create a design that meets your specific needs, you can ensure that your iron castings are built to the highest standards of quality. This can translate into better performance, increased efficiency, and reduced downtime.

If you require a complex shape or design for your iron casting, customization can ensure that the casting is produced to precise specifications, which can lead to improved accuracy and a better overall finish. This can improve the durability of the casting, reduce the likelihood of damage, and ultimately lead to better overall performance.

3. Enhanced Branding Opportunities

Customizing and personalizing your iron castings also offers enhanced branding opportunities. You can choose to have your company logo or name stamped onto the castings, which can help increase brand recognition and awareness. This can be particularly useful if your castings are visible to customers or clients.

If you’re manufacturing a piece of equipment that will be visible to end-users or installed in a public space, adding your branding to the casting can help to create a stronger brand identity and reinforce your company’s presence in the market.

4. Cost-Effective Solutions

Contrary to what you might think, customizing and personalizing your iron castings doesn’t have to be expensive. In fact, it can be a cost-effective solution. By tailoring your castings to your specific needs, you can reduce waste, improve efficiency, and ultimately save money in the long run.

If you require a specific size or shape of iron casting that is not readily available on the market, customization can allow you to create a casting that fits your needs, without requiring the purchase of expensive machinery or tooling. This can be particularly useful for small production runs or specialty applications where the cost of custom tooling would be prohibitively expensive.

5. Increased Customer Satisfaction

Customizing and personalizing your iron castings can lead to increased customer satisfaction. By providing products that are tailored to their needs and specifications, you can create a positive experience for your customers. This can lead to increased loyalty, repeat business, and positive word-of-mouth referrals.

If you’re manufacturing a piece of equipment for a customer, customization allows you to create a product that fits their exact requirements, which can lead to greater satisfaction with the final result. This can help to build a strong, long-lasting relationship with your customers, which can lead to increased business opportunities and a more stable revenue stream.

6. Improved Productivity

Customizing and personalizing your iron castings can improve your overall productivity. By tailoring your castings to your specific needs, you can create products that are more efficient and easier to use. This can help to reduce the time and resources required to produce your products, which can lead to increased productivity and profitability.

For example, if you’re producing a piece of equipment that requires a custom iron casting, customization can allow you to create a casting that is specifically designed for that application. This can lead to improved productivity and reduced downtime, which can ultimately lead to increased profitability.

7. Greater Design Flexibility

Customizing and personalizing your iron castings offers greater design flexibility. You can create castings that have complex shapes and features that might not be possible with off-the-shelf castings. This means that you can create products that are more visually appealing, more functional, and more efficient.

If you’re designing a piece of equipment that requires a unique shape or design, customization can allow you to create a casting that perfectly matches your vision. This can lead to greater design flexibility and more efficient use of space and resources.

8. Reduced Maintenance Costs

Customizing and personalizing your iron castings can also lead to reduced maintenance costs. By creating a design that is tailored to your specific needs, you can ensure that your castings are more durable and require less maintenance over time. This can save you money in the long run and reduce downtime due to maintenance issues.

9. Faster Turnaround Time

Customizing and personalizing your iron castings can lead to faster turnaround times. By working closely with your manufacturer, you can ensure that your castings are produced quickly and efficiently. This means that you can get your products to market faster, which can give you a competitive advantage.

If you need a custom iron casting for a prototype or a small production run, customization can allow you to quickly produce the casting and get it to market faster than if you were using off-the-shelf castings. This can help you stay ahead of the competition and take advantage of new opportunities as they arise.

10. Improved Safety and Durability

Customizing and personalizing your iron castings can also lead to improved safety and durability. By creating a design that is tailored to your specific needs, you can ensure that your castings are more resistant to wear and tear, which can reduce the risk of accidents or failures. This can be particularly useful in industries where safety is a critical concern, such as construction or transportation.

11. Increased Innovation

Customizing and personalizing your iron castings can lead to increased innovation. By working closely with your manufacturer to create custom castings, you can explore new design ideas and technologies. This can lead to products that are more innovative, more efficient, and more effective.

For example, if you’re designing a new piece of equipment, customization can allow you to explore new design ideas and technologies that might not be possible with off-the-shelf castings. This can lead to products that are more innovative and more competitive in the marketplace.

12. Increased Environmental Sustainability

Finally, customizing and personalizing your iron castings can lead to increased environmental sustainability. By tailoring your castings to your specific needs, you can reduce waste and minimize the environmental impact of your manufacturing process. This can be particularly useful in industries where environmental sustainability is a key concern, such as renewable energy or green technology.

Conclusion

In conclusion, customizing and personalizing with iron castings offers a range of benefits that can make them even more valuable for your specific needs. By tailoring your castings to your exact specifications, you can improve quality, performance, branding opportunities, cost-effectiveness, customer satisfaction, improved efficiency, greater design flexibility, reduced maintenance costs, faster turnaround time, improved safety and durability, increased innovation, and increased environmental sustainability. So, if you’re in need of iron castings, consider working with a manufacturer who offers customization and personalization services.

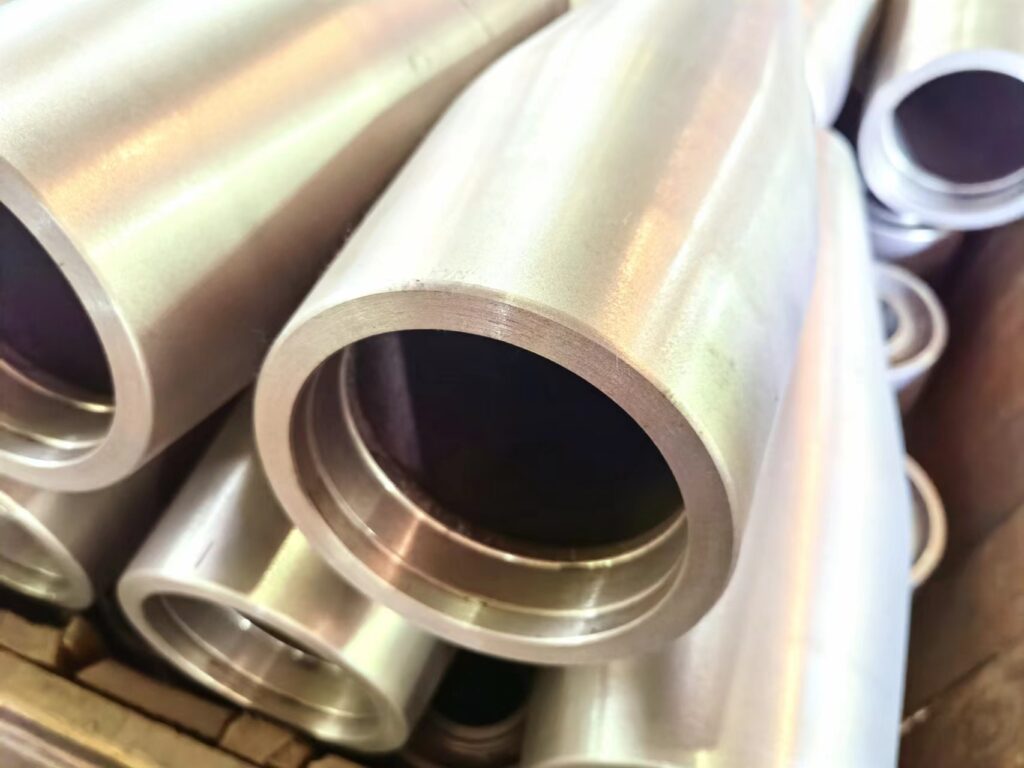

We are Castimoo, a supplier dedicated to the production of gray iron and ductile iron castings. We have over 30 years of experience in the iron casting industry. We specialize in custom iron castings for customers at home and abroad, and our products are well accepted by our customers. If you have plans to customize iron castings, please feel free to contact us. We are always here for you.