Introduction

Iron casting is an essential part of many industries, from automotive and aerospace to construction and infrastructure. However, the environmental impact of iron casting is significant, as it involves the use of large amounts of energy, water, and raw materials. Additionally, the waste generated during the casting process can have harmful effects on the environment if not managed properly.

As a result, many foundries and iron casting suppliers are looking for ways to reduce their environmental impact and adopt sustainable practices. In this blog post, we will explore some of the sustainable practices that iron casting suppliers can implement to minimize their environmental impact.

1. Energy Efficiency

One of the most significant contributors to the environmental impact of iron casting is the amount of energy consumed during the casting process. Foundries typically use large amounts of electricity and natural gas to melt iron, and this energy consumption can be reduced by implementing energy-efficient practices. One example is the use of high-efficiency furnaces, which can significantly reduce energy consumption while maintaining the quality of the casting.

Another approach to increasing energy efficiency is the use of waste heat recovery systems. These systems capture the heat generated during the casting process and use it to preheat air or water, which reduces the energy required to heat these materials. Some foundries also use renewable energy sources, such as solar or wind power, to reduce their reliance on fossil fuels.

2. Water Conservation

Water is another essential resource used in the iron casting process, and foundries can minimize their water usage by implementing water conservation measures.

For example, foundries can recycle and reuse water instead of using fresh water for every casting. They can also implement measures to prevent leaks and spills and reduce the amount of wastewater generated during the casting process.

Another approach to reducing water usage is the use of dry sand molds instead of traditional green sand molds. Dry sand molds do not require water to create the mold, which can significantly reduce water usage and wastewater generation.

Additionally, foundries can use water treatment technologies to treat the wastewater generated during the casting process and minimize its environmental impact.

3. Raw Material Reduction

Iron casting involves the use of raw materials such as iron, coke, and limestone, and foundries can reduce their environmental impact by minimizing the amount of raw materials used.

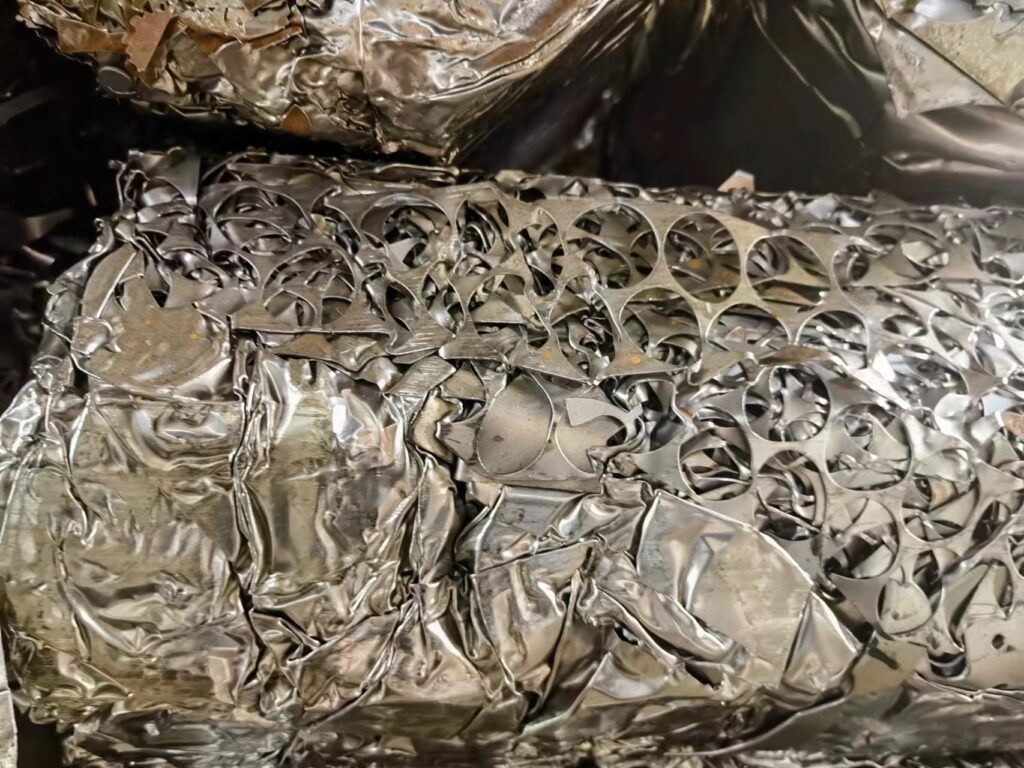

One approach is the use of recycled materials, such as scrap iron or steel, which can reduce the need for virgin materials.

Foundries can also implement process optimization and waste reduction measures to minimize the amount of material that is wasted during the casting process.

4. Emissions Reduction

Foundries emit a variety of pollutants, including particulate matter, volatile organic compounds (VOCs), and greenhouse gases. These emissions can have harmful effects on the environment and human health.

Foundries can implement measures to reduce emissions, such as using low-emission fuels or installing emissions control technologies, such as scrubbers or baghouses.

Another approach to emissions reduction is the use of process optimization and automation. By optimizing the casting process, foundries can reduce the amount of emissions generated while maintaining quality. Automation can also help reduce emissions by minimizing the need for manual interventions, which can result in process inefficiencies and increased emissions.

5. Waste Reduction

Iron casting generates a significant amount of waste, including slag, dust, and sand. This waste can have harmful effects on the environment if not managed properly. Foundries can implement measures to reduce waste generation, such as using reusable molds or reducing the amount of excess material used in the casting process.

Additionally, foundries can implement waste management systems, such as recycling or reusing waste materials or disposing of waste in an environmentally responsible manner.

6. Closed-Loop Systems

Closed-loop systems are a sustainable practice that involves using a closed-loop system for cooling and lubrication in the casting process. This system captures and recirculates cooling and lubricating fluids, reducing the need for fresh water and minimizing wastewater generation.

7. Lean Manufacturing

Lean manufacturing is a sustainable practice that involves optimizing the manufacturing process to eliminate waste, reduce costs, and improve efficiency. By implementing lean manufacturing principles, foundries can minimize their environmental impact by reducing material waste, energy consumption, and emissions.

8. Life Cycle Assessment (LCA)

Life cycle assessment is a sustainable practice that involves analyzing the environmental impact of a product or process throughout its entire life cycle, from raw material extraction to disposal. By conducting an LCA, foundries can identify areas of their process that have the highest environmental impact and implement targeted sustainability measures to minimize that impact. LCA can also help foundries identify opportunities for product or process redesign to improve sustainability.

9. Green Procurement

Green procurement is a sustainable practice that involves selecting environmentally friendly materials and suppliers. Foundries can adopt green procurement practices by choosing raw materials that are sustainably sourced or have a lower environmental impact.

They can also work with suppliers who have sustainable practices and certifications, such as ISO 14001, which indicates that the supplier has an effective environmental management system in place.

10. Employee Engagement

Employee engagement is a sustainable practice that involves involving employees in sustainability initiatives and providing them with the knowledge and tools they need to reduce their environmental impact.

Foundries can engage employees in sustainability by providing training and education on sustainability topics, encouraging employee suggestions and feedback on sustainability initiatives, and recognizing and rewarding sustainability efforts. Engaged employees can help identify areas of improvement and contribute to a culture of sustainability within the organization.

Conclusion

This blog post summarizes 10 tips for reducing environmental impact in the iron casting industry, which are Energy Efficiency, Water Conservation, Raw Material Reduction, Emissions Reduction, Waste Reduction, Closed- Loop Systems, Lean Manufacturing, Life Cycle Assessment (LCA), Green Procurement and Employee Engagement.

Iron casting is a vital industry that is essential for many modern applications. However, the environmental impact of iron casting can be significant, and foundries must take action to do their part to protect the environment.

We are Castimoo, a supplier dedicated to the production of iron castings. We respond to the national policy and give our action in energy saving and emission reduction. Especially in casting material, we use scrap steel and cast iron chips, which is not only environmental friendly, but also the cost of material is reduced down. If you need to purchase iron castings, please feel free to contact us.