Iron Casting With Comprehensive Solutions

Do you need to purchase gray iron and ductile iron casting products? Here is our one-stop service and the ultimate solutions for you.

Earthworks

Agriculture

Generators

Valves

Application Areas

The application of iron casting parts is very wide. Whether it is flying in the sky, running on the ground, swimming in the sea are closely related to the castings.

- Industry, Agriculture, Service

- Motor, Engine, Generator

- Pump, Valve, Equipment

- Airplane, Automotive, Ship

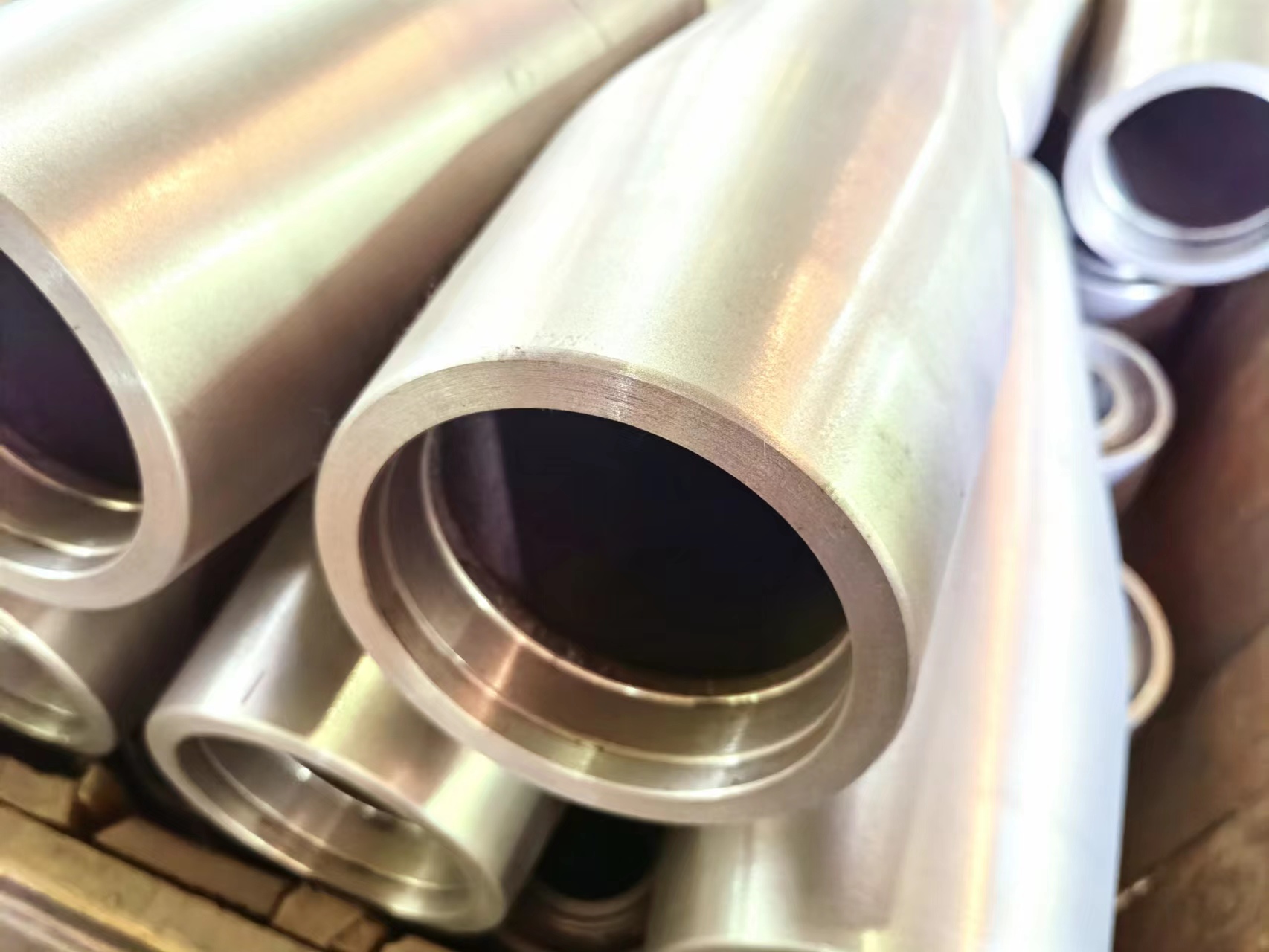

Successful Customized Projects

We customize gray iron 150 (20A) – 350 (50A) grades and ductile iron 400/18 (60-42-10) – 800/2 (120-90-02) grades. A full range of solutions to meet your needs.

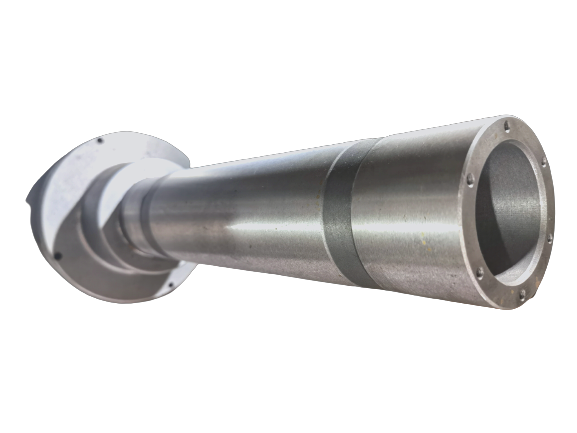

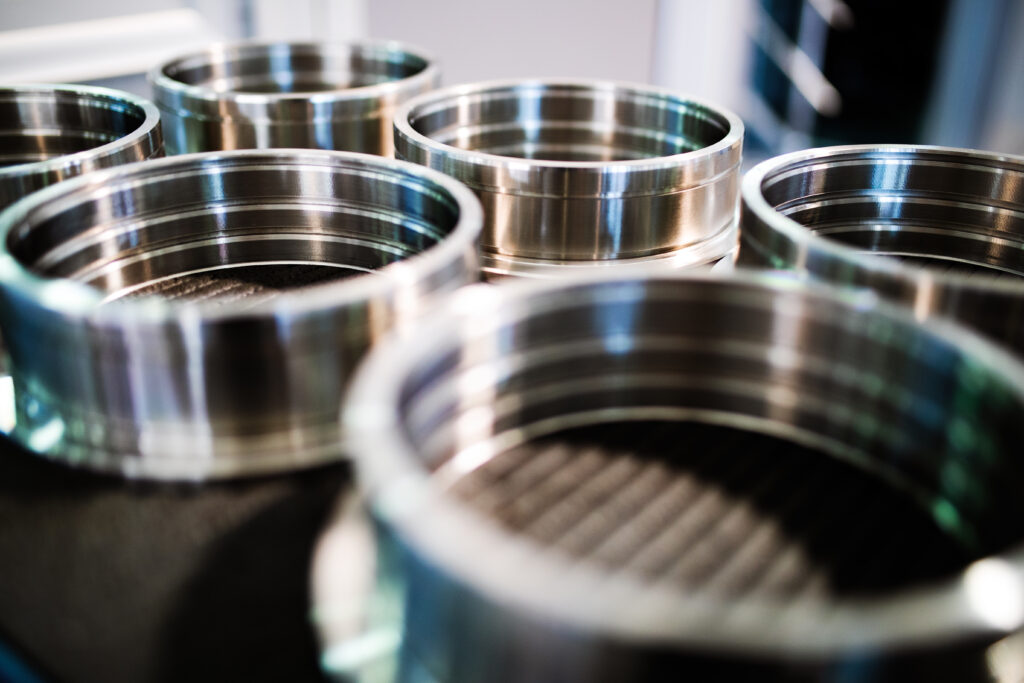

Alternator Cover

Gray Iron 250 (35A)

Motor bushing

Gray Iron 250 (35A)

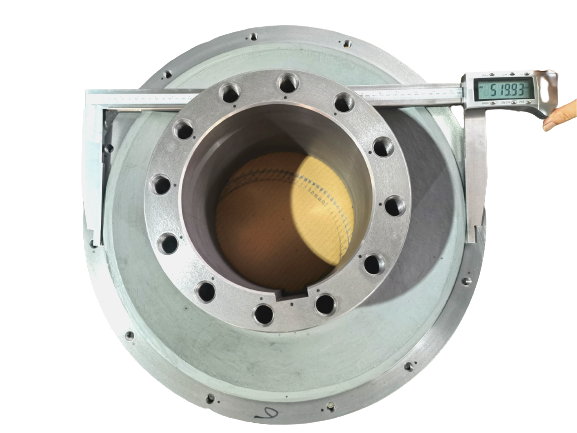

Generator housing

Gray Iron 250 (35A)

Rectifier support base

Ductile lron 400-15 (65-45-12)

Drive Tray

Ductile lron 400-15 (65-45-12)

Roller Sheave

Ductile lron 600-3 (80-60-03)

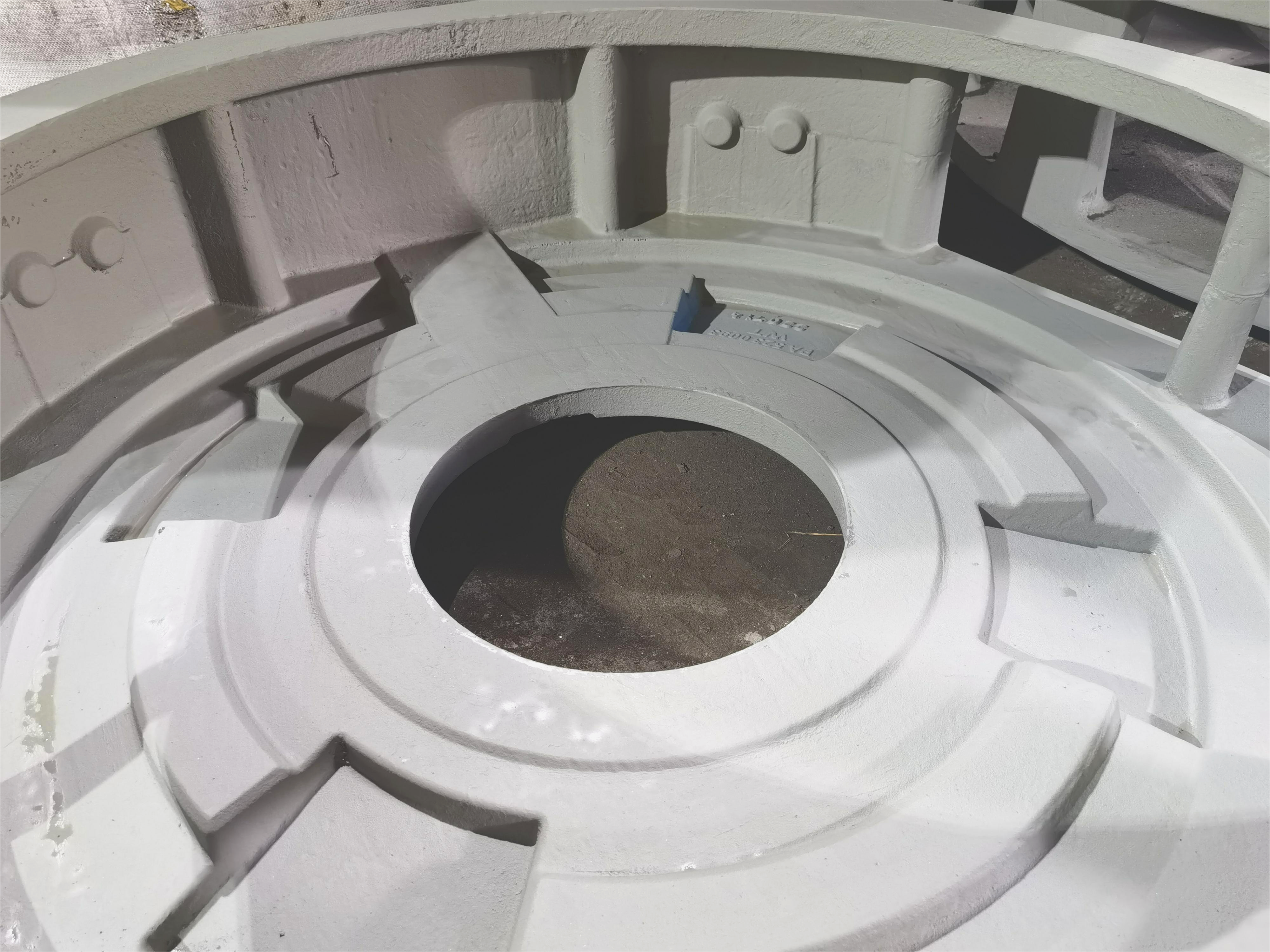

Sand Casting Services

2 green sand automatic molding lines and 1 resin sand molding line to provide you with the most complete casting service.

Green Sand Casting

We control the quality of the sand by 4 parameters. They are the effective bentonite content, compactability, wet compressive strength and moisture control.

Resin Sand Casting

It has high thermal stability and low permeability and is usually used for large precision castings with complex shapes. Its advantages include good surface finish, excellent dimensional accuracy and repeatability.

A complete set of professional Solution

From OEM drafting to tooling developing, from casting to machining, from packing to shipping, we have one-stop service to customize the best quality iron casting products for you.

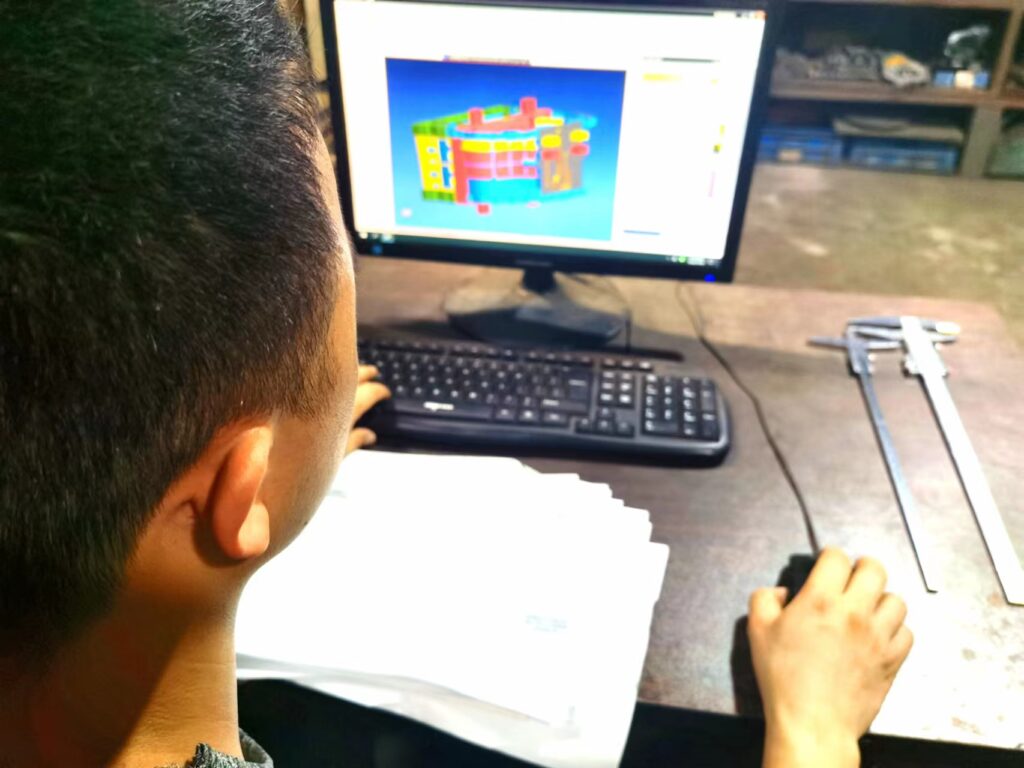

3D Drafting

The team led by university professors to design a reasonable pouring system for ductile iron, which means you no longer worry about shrinkage problem.

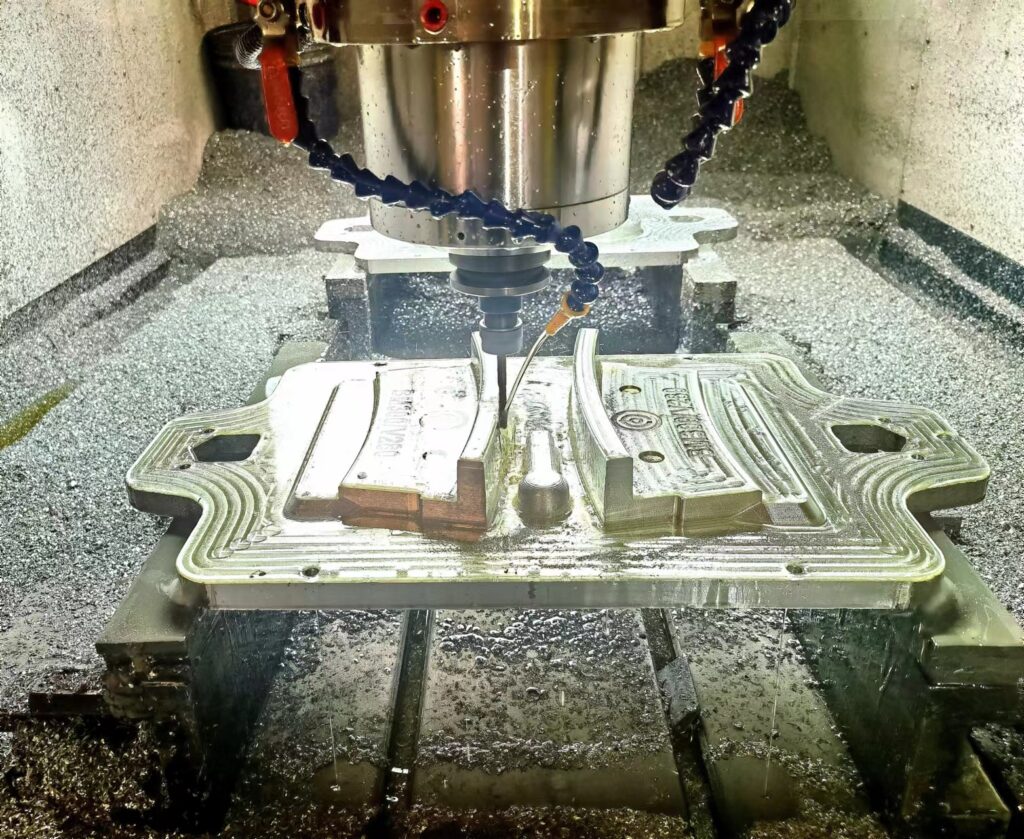

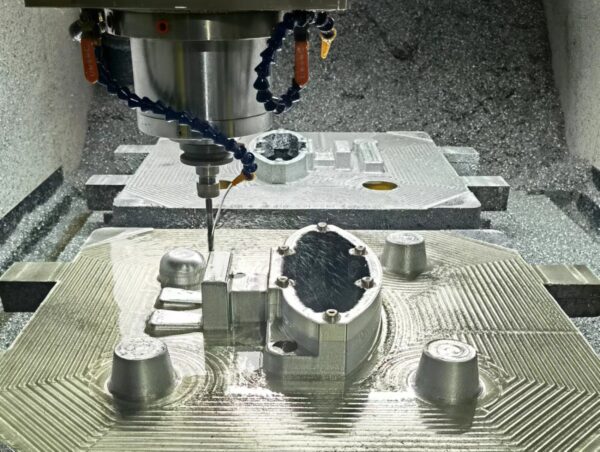

Tooling Fabricating

Just 10 days from designing the tooling to producing the sample, to ensure you can get the sample for evaluation in the shortest time and develop your customers quickly.

Casting

Two automatic molding lines, three sets of medium frequency electric furnace, with more than 50 professional workers working in two shifts at your service, to make sure that you can get the best service experience.

Machining

Professional machining team with 20+ years of experience. With 10+ NC and CNC machines, ensure on-time delivery. Quality inspection management system, strict control of processing accuracy.

Packing

Before packing, we will do a good job of rust prevention treatment, there are two kinds of water-based and oil-based rust prevention methods for your choice. The wooden boxes for export are also in accordance with the export regulations.

Shipping

We have been working with local logistics and freight forwarders for many years, to ensure that you receive your goods in the shortest time. And the best quality service and the most suitable price will be provided.

How we ensure the quality

ISO9001 quality management system, strict control of each step of iron casting production.

- Control of raw materials to ensure the stability of raw material composition

- Metallograph to observe graphite morphology.

- Hardness tester to measure the hardness of the casting.

- Spectrometer to detect the composition of the casting, the composition of each furnace must be recorded.

- Quality inspection management system, strict control of processing accuracy.

General Breakdown of Costs

All the money paid to Castimoo for purchasing their iron casting products is secure. A general breakdown of costs involved in importing goods from China as below.

Product Cost

This is the cost of the product you intend to purchase from the Chinese supplier, including the cost of tooling, manufacturing, packaging, and labeling.

Shipping Cost

This includes the cost of shipping the product from the supplier's location in China to your destination. The shipping cost may depend on factors such as the size and weight of the product, the shipping method (sea or air), and the distance between the supplier and your location.

Customs Duties and Taxes

When importing goods from China, you will be required to pay customs duties and taxes. The amount of duties and taxes you will be required to pay will depend on the country you are importing to and the product you are importing.

Insurance Cost

You may also need to pay for insurance to protect your product during transit.

Brokerage Fees

You may need to hire a customs broker to handle the customs clearance process. The broker will charge a fee for their services.

Bank Fees

You may also be required to pay bank fees for international wire transfers or currency exchange.

Estimated Lead Time

Time is money. Everything we do is for our customers to receive the highest quality products in the fastest possible time.

Sampling Time

We design and process the molds ourselves, and we can produce samples in just 15 days. Provide you with the most efficient design service.

Production Time

Mass production, strictly according to the production plan. Perfect production equipment and staffing to ensure timely and quick delivery.

Shipping Time

Cooperate with logistics and freight forwarding for many years, we can provide the safest and fastest transportation solution.

Knowledge of purchasing iron castings

These articles are some of the problems you will encounter when purchasing casting products and how to deal with them, for your reference.

Reducing Procurement Costs: A Guide to Affordable Iron Castings

In this comprehensive guide, we will explore the factors that affect the cost of iron castings and provide practical strategies to help you reduce procurement costs while maintaining quality and reliability.

How to Select the Right Metal Casting Process for Your Project: A Comprehensive Guide

In this comprehensive guide, we will walk you through the essential steps to make an informed decision when it comes to metal casting.

Unlocking Efficiency: How to Determine the Average Production Capacity of an Iron Casting Manufacturer

In this comprehensive guide, we’ll walk you through the process, helping you make informed decisions that can significantly impact your project’s success.

Mastering Sand Casting: Overcoming Common Challenges for High-Quality Iron Castings

In this comprehensive guide, we will delve into the common challenges encountered in sand casting and provide valuable insights on how to overcome them.

Simplified Shipping Solutions: How Castimoo Manages Logistics to Your Doorstep

In this article, we’ll explore how Castimoo handles logistics and shipping arrangements to your country, making the process hassle-free and efficient.

Ensuring Quality: Why Providing Samples Before Bulk Orders Matters in Iron Casting

In this article, we will delve deep into the significance of this practice and how it can make all the difference in your iron casting projects.

The FAQs through out the process

To save you from worries, here are some facts you need to know about our service.

It depends on products, generally speaking, it can be finished in 10 days.

1, We have a professional R&D and design team led by university professors.

2, Unique design of pouring system, which can solve the problem of shrinkage of ductile iron products.

3, Equipped with foam mold carving machine, machining center and other machines to process molds, guaranteeing that samples can be produced in 10 days.

1, We select high quality and stable raw material suppliers of scrap steel.

2, Testing laboratory equipped with testing instruments to strictly test the metallic image, composition and hardness of the material.

3, We record the temperature of iron in each furnace as well as the composition hardness to ensure the material stability.

1, We screen customers who reasonably match the needs of both parties and provide value to the counterpart.

2, Implementing a two-shift work system to control the production schedule according to the plan.

3, Equipped with two automatic molding lines and more than 10+ sets of NC processing equipment to guarantee production efficiency.

1, Of course you can, and you are very welcome to come to China.

2, But it’s still during the epidemic, and there are still strict restrictions on foreign arrivals.

3, If it is not convenient, we support online factory inspection.

1, If your product and needs are beyond our capabilities, I think this will happen. However, there are solutions.

2, We are the executive director of Fujian Province Foundry Association, and we interoperate with many quality foundry suppliers.

3, We will exchange experiences and opinions with each other and do our best to meet your needs.