Introduction

In the world of manufacturing, iron castings are essential components used in a wide range of industries, from automotive to construction. For businesses that rely on iron castings, managing procurement costs is a critical concern. Whether you operate in China, the USA, Japan, Europe, or any other part of the world, understanding how to reduce the cost of procuring iron castings can significantly impact your bottom line.

At Castimoo, we understand the importance of cost-effective solutions for iron castings. In this comprehensive guide, we will explore the factors that affect the cost of iron castings and provide practical strategies to help you reduce procurement costs while maintaining quality and reliability.

Understanding the Factors Affecting Procurement Costs

Before delving into cost reduction strategies, it’s crucial to understand the key factors that influence the cost of iron castings. These factors encompass various aspects of the casting process and can be categorized as follows:

- Material Selection:

The choice of material significantly impacts the cost of iron castings. Different types of iron alloys have varying costs, and selecting the appropriate material for your application is crucial. While cost considerations are important, it’s equally essential to ensure that the chosen material meets the performance and durability requirements of the end product. - Design and Specifications:

The design of the casting and its specifications play a vital role in cost management. Complex designs with intricate details can result in higher production costs. Therefore, it’s essential to strike a balance between design aesthetics and manufacturability. Often, simple and straightforward designs are more cost-effective to produce. - Production Volume:

Economies of scale come into play when ordering iron castings. Higher production volumes often lead to lower per-unit costs. Smaller quantities, on the other hand, may come with a premium. Hence, it’s advisable to plan for larger production runs to reduce unit costs over time. - Quality Standards and Certifications:

Adherence to quality standards and certifications can influence costs. Meeting industry standards ensures the production of reliable and safe iron castings. While achieving and maintaining these standards may involve some initial investment, the long-term benefits in terms of reduced defects and rejections can lead to substantial cost savings.

Optimize Design and Specifications

The design of your iron casting has a significant impact on its cost. While it’s important to create castings that meet your functional requirements, optimizing the design for manufacturability can help you reduce production costs. Here are some tips for achieving cost-effective designs:

- Simplify Geometry:

Complex shapes and intricate details may increase production costs. Simplifying the geometry of your casting can make it easier and less expensive to manufacture. Consider whether all the design elements are essential and whether there are ways to achieve the same function with a simpler design. - Use Standard Tooling:

Standardized tooling and molds can be more cost-effective than custom tooling. Where possible, design your casting to fit within existing tooling or molds to avoid additional setup costs. - Reduce Weight:

The weight of the casting directly affects material costs and transportation expenses. If possible, design your casting to be lighter while maintaining structural integrity. This can lead to significant savings in the long run. - Minimize Undercuts:

Undercuts in the design can make it more challenging to remove the casting from the mold, increasing production time and costs. Designing your casting with minimal undercuts can streamline the manufacturing process.

Sourcing the Right Supplier

Selecting the right supplier for your iron castings is a critical decision that can greatly impact procurement costs. At Castimoo, we prioritize cost-effective and reliable solutions. When choosing a supplier, consider the following factors:

- Reputation:

Research the reputation of potential suppliers. Look for reviews, testimonials, and case studies that demonstrate their track record of delivering quality products on time and within budget. - Location:

Proximity to your business can be a key factor in managing transportation costs. Local suppliers may offer advantages in terms of reduced shipping expenses and faster lead times. - Capacity:

Evaluate the supplier’s production capacity. A supplier with the capacity to handle your production volume efficiently is more likely to offer competitive pricing. - Flexibility:

Look for a supplier that is willing to work with you to optimize your design and find cost-effective solutions. A flexible supplier can help you achieve your cost reduction goals.

Volume Discounts and Consistency

One effective way to reduce procurement costs is by ordering in larger quantities. Here’s how this approach can benefit your business:

- Economies of Scale:

Ordering in bulk often leads to lower production costs per unit. Suppliers can spread fixed costs over a larger number of castings, resulting in savings that are passed on to you. - Reduced Setup Costs:

Suppliers often charge setup fees for each production run. By ordering larger quantities, you can amortize these setup costs over more units, reducing the cost per casting. - Improved Negotiation Power:

With larger orders, you gain stronger negotiation leverage with your supplier. You can negotiate better pricing, payment terms, and other favorable terms. - Consistency of Supply:

Long-term partnerships with suppliers can ensure a consistent and reliable supply of iron castings. This consistency can lead to better cost forecasting and planning for your business.

Material Selection and Cost Reduction Strategies

Material costs are a significant part of your procurement expenses. Selecting the right material for your iron casting is essential for cost reduction. Here are some strategies to consider:

- Material Alternatives:

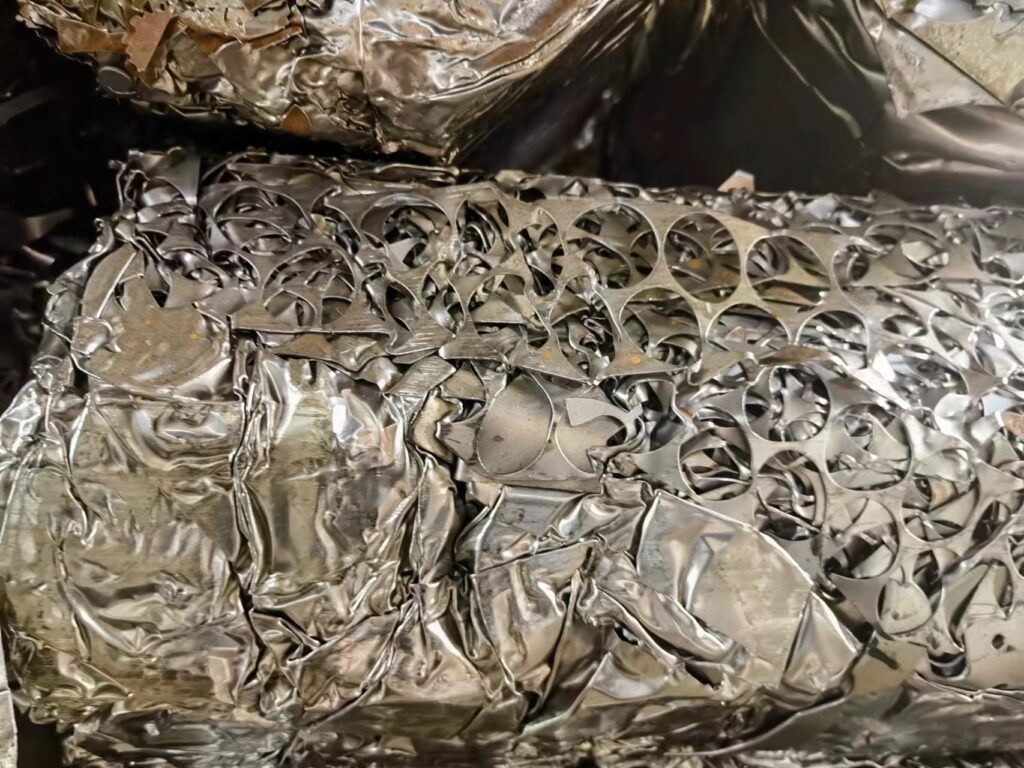

Explore alternative materials that meet your performance requirements. In some cases, a less expensive material may perform just as well as a costlier one, reducing overall costs. - Recycled Materials:

Some suppliers offer recycled or reclaimed iron, which can be more cost-effective than using only virgin materials. However, ensure that quality is not compromised when using recycled materials. - Minimize Material Waste:

Work with your supplier to minimize material waste during the casting process. Advanced molding and gating techniques can help reduce material usage, lowering costs. - Material Standardization:

Standardizing the materials you use for your iron castings can lead to cost savings by allowing for bulk purchasing and reducing the complexity of material inventory management.

Quality Control and Efficiency

Efficient production processes and stringent quality control measures are key to reducing procurement costs in the long run. Here are some strategies to consider:

- Lean Manufacturing:

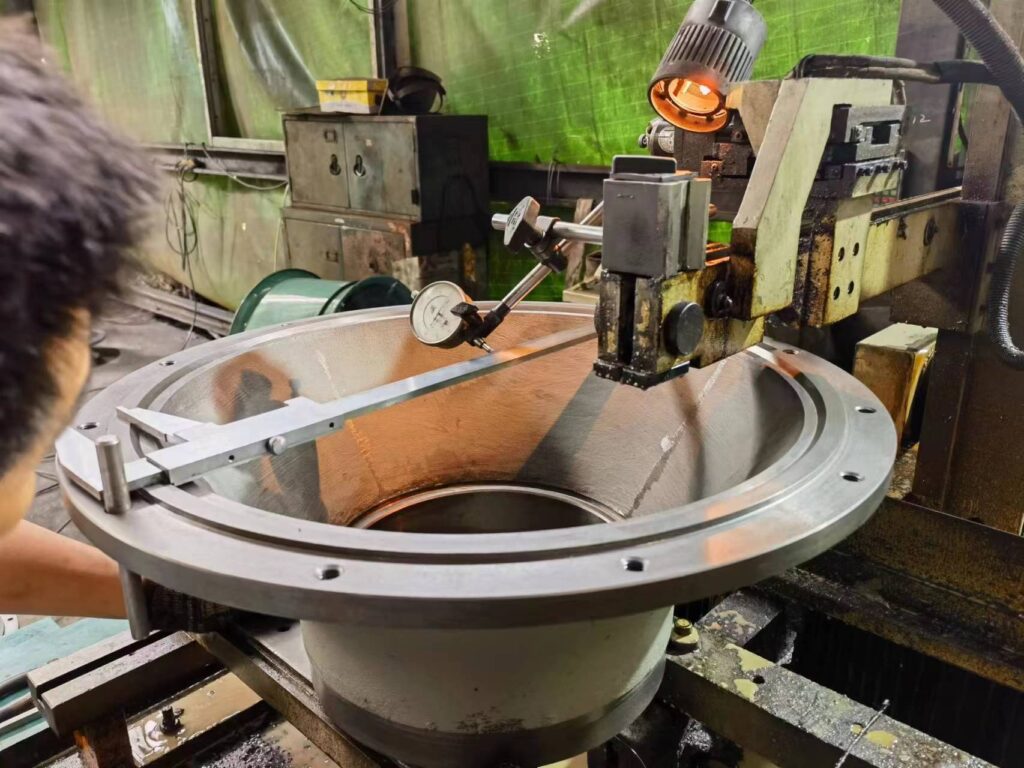

Implement lean manufacturing principles to streamline production processes. Reduce unnecessary steps and eliminate waste to lower production costs. - Quality Inspections:

Regular quality inspections can identify and address defects early in the production process, reducing the cost of rework and scrap. - Employee Training:

Well-trained and skilled employees are more efficient and produce higher-quality castings. Invest in employee training and development to improve efficiency and reduce defects. - Process Optimization:

Continuously evaluate and optimize your production processes to identify opportunities for cost reduction. Technology upgrades and automation can enhance efficiency.

Innovations and Technology

Staying up-to-date with technological advancements can lead to cost savings in the casting process. As an iron casting supplier, Castimoo prides itself on adopting innovative techniques and technologies. Here are some areas where technology can drive cost reduction:

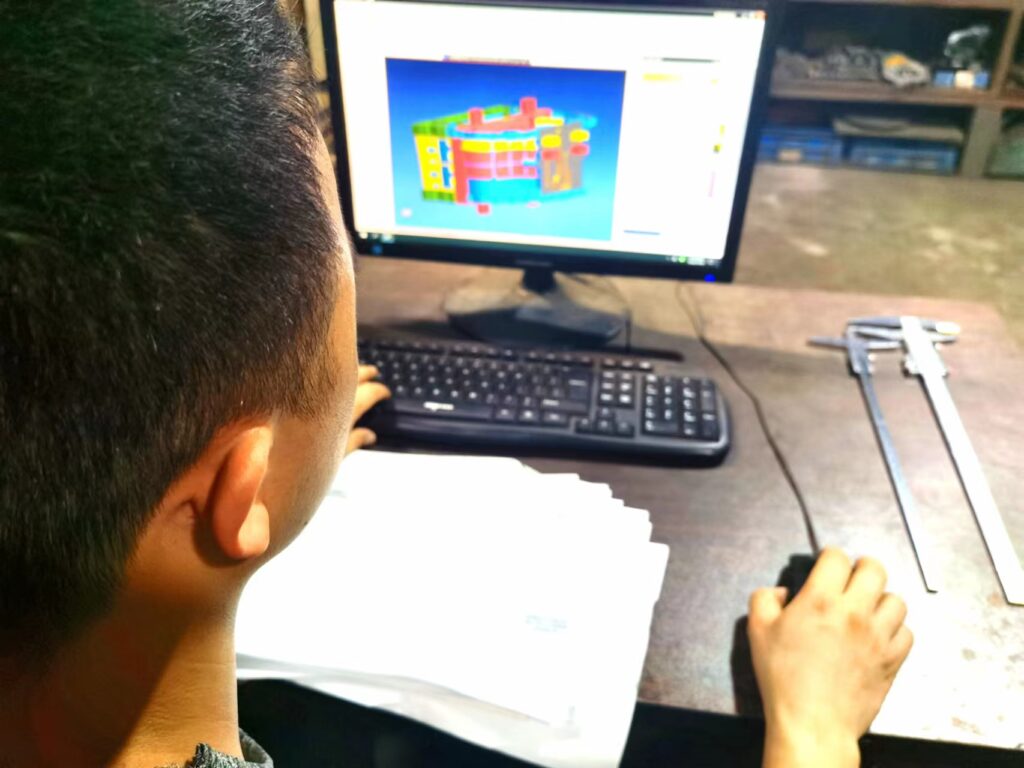

- Computer-Aided Design (CAD):

CAD software allows for precise and efficient casting design. It enables designers to make design modifications that reduce costs without compromising quality. - Simulation Software:

Casting simulation software can predict potential defects and issues in the design, allowing for adjustments before the casting is produced. This reduces the cost of rework and scrap. - 3D Printing:

3D printing can be used for creating prototypes and patterns, saving time and cost in the design and development phase. - Automation:

Automated manufacturing processes reduce the need for manual labor and can lead to significant cost savings over time.

Case Studies and Success Stories

To illustrate the practical application of these cost reduction strategies, here are a few case studies and success stories from Castimoo’s experience in the iron casting industry:

Case Study 1: Redesign for Cost Reduction

A client in the automotive industry approached Castimoo with a complex iron casting design. By collaborating with the client to simplify the design while maintaining its functionality, the cost of production was reduced by 15%. The client was able to order in larger quantities, further reducing costs, and resulting in significant long-term savings.

Case Study 2: Material Optimization

Another client in the construction industry was using a premium iron alloy for their castings. Castimoo worked with the client to identify an alternative material that met the necessary performance standards. This switch to a more cost-effective material resulted in a 10% reduction in material costs without compromising quality.

Case Study 3: Lean Manufacturing Implementation

A long-term partnership with a client in the agricultural machinery sector allowed Castimoo to implement lean manufacturing principles. By eliminating waste and optimizing processes, the client saw a 12% reduction in production costs and a 20% reduction in defects.

These case studies demonstrate how a strategic approach to iron casting procurement can yield substantial cost savings and improve overall business performance.

Conclusion

Reducing the procurement cost of iron castings is an ongoing process that requires careful consideration of various factors, from material selection and design optimization to choosing the right supplier and implementing cost-effective production methods. Castimoo is committed to helping businesses in China, the USA, Japan, Europe, and beyond achieve affordable and high-quality iron castings.

By understanding the factors that impact costs and implementing the strategies outlined in this guide, you can drive down procurement expenses, enhance your competitive edge, and ensure the continued success of your business.

Call to Action

Ready to reduce your iron casting procurement costs? Contact Castimoo today to discuss your specific needs and discover how our cost-effective solutions can benefit your business. We’re here to help you achieve your cost reduction goals and provide reliable, top-quality iron castings for your projects.