Introduction

In the world of manufacturing, quality is king. Whether you’re producing intricate automotive parts, sturdy construction materials, or any other iron castings, ensuring that each piece meets strict quality standards is paramount.

For businesses in need of iron castings, this raises an important question: Can the manufacturer provide samples for quality evaluation before placing a bulk order? In this article, we will delve deep into the significance of this practice and how it can make all the difference in your iron casting projects.

The Significance of Quality Assurance in Iron Casting

Before we dive into the specifics of sample evaluation, let’s first understand why quality assurance is so crucial in the iron casting industry.

1. Safety and Reliability

Iron castings often find their way into applications where safety and reliability are paramount. Think about the automotive industry, where critical components like engine blocks and brake rotors must perform flawlessly to ensure driver and passenger safety. In such applications, any compromise in quality can have catastrophic consequences.

2. Performance and Durability

In industries like construction and agriculture, iron castings play a pivotal role in heavy machinery. These machines endure harsh conditions and heavy loads, and their performance and durability depend on the quality of the cast components. Low-quality castings can lead to frequent breakdowns, downtime, and increased maintenance costs.

3. Cost Efficiency

Quality isn’t just about safety and reliability; it’s also about cost-efficiency. High-quality iron castings tend to last longer, require less maintenance, and offer better performance, ultimately saving businesses money in the long run.

4. Reputation and Customer Trust

A single quality issue can tarnish a manufacturer’s reputation and erode customer trust. Companies that consistently deliver high-quality products build strong, long-lasting relationships with their customers.

In light of these factors, it becomes evident that maintaining rigorous quality standards is non-negotiable in the iron casting industry. This is where the practice of providing samples before bulk orders comes into play.

Understanding the Sample Evaluation Process

At Castimoo, we understand the paramount importance of quality assurance in iron casting. That’s why we offer our customers the opportunity to evaluate samples before committing to bulk orders. But what exactly does this process entail?

When you express interest in our iron casting services, we’ll work closely with you to determine your specific requirements. We’ll consider factors such as the type of casting, the material composition, dimensional tolerances, and surface finish. Once we have a clear understanding of your needs, we’ll proceed to create samples that accurately represent the quality and characteristics of the final product.

Our sample evaluation process includes the following steps:

1. Sample Preparation

Our team of skilled technicians will meticulously craft a small batch of iron castings based on your specifications. This involves setting up the casting molds, melting the iron, and pouring it into the molds to create the samples.

2. Quality Control

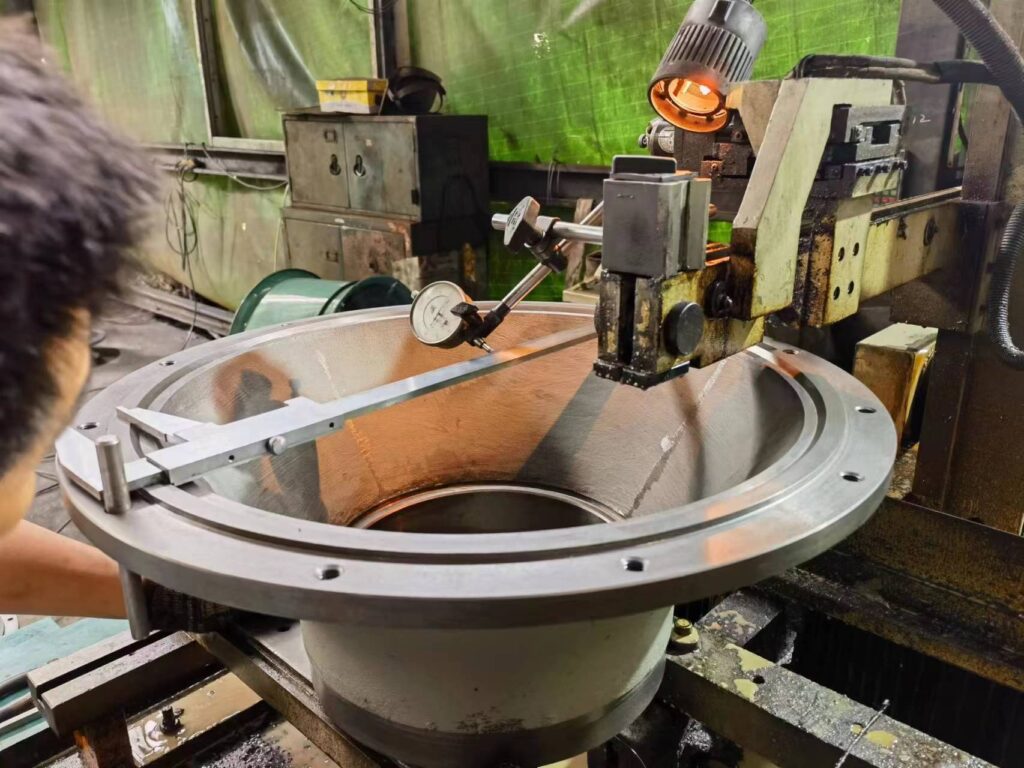

During and after the casting process, our quality control team conducts thorough inspections to ensure that each sample meets the agreed-upon standards. This includes dimensional checks, visual inspections, and material testing.

3. Surface Finish

Depending on your requirements, we will finish the samples to achieve the desired surface quality, which may involve processes like shot blasting, sanding, or painting.

4. Packaging and Shipping

Once the samples pass our stringent quality checks, we carefully package them to prevent damage during transit and ship them to your location.

5. Consultation and Feedback

After receiving the samples, we encourage open communication with our customers. We want to ensure that the samples align with your expectations and requirements. If any adjustments or refinements are needed, we’re here to accommodate your feedback.

By offering this sample evaluation process, we provide our customers with a tangible preview of the quality and craftsmanship they can expect from our iron castings.

Benefits of Requesting Samples Before Bulk Orders

Now that we’ve outlined the sample evaluation process, let’s explore the tangible benefits of requesting samples before placing bulk orders:

1. Risk Reduction

Requesting samples is a proactive step in risk mitigation. It allows you to assess the quality and suitability of the iron castings before committing to a large-scale production run. If the samples don’t meet your expectations, you can address the issues and make necessary adjustments without incurring significant costs.

2. Confidence in Quality

By evaluating samples, you gain confidence in the quality of the final product. You can visually inspect the castings, perform material tests, and ensure that they meet your dimensional requirements. This confidence is especially valuable for industries where precision and consistency are critical.

3. Peace of Mind

Knowing that you have thoroughly evaluated and approved the samples can provide peace of mind. It eliminates the uncertainty that often accompanies large orders and minimizes the chances of unpleasant surprises down the road.

4. Customization and Fine-Tuning

Samples offer an opportunity for customization and fine-tuning. If you have specific design or performance requirements, you can work with the manufacturer to make adjustments based on the sample evaluation.

5. Cost-Efficiency

While producing samples incurs some initial costs, it can lead to significant cost savings in the long term. Discovering quality issues after a bulk order has been manufactured can be far more expensive to rectify.

6. Alignment with Standards

Samples ensure that your iron castings align with industry standards and regulatory requirements. This is especially crucial in sectors like aerospace and defense, where adherence to strict standards is non-negotiable.

Case Studies: The Power of Sample Evaluation

To illustrate the real-world impact of sample evaluation, let’s explore a couple of case studies where this practice played a crucial role:

Case Study 1: Automotive Component Manufacturer

A leading automotive component manufacturer was in the process of selecting a supplier for their critical engine block castings. Given the high-stakes nature of the automotive industry, they requested samples from several potential suppliers, including Castimoo.

After evaluating the samples we provided, the manufacturer chose Castimoo as their trusted partner. Our samples showcased not only the high quality of our castings but also our commitment to precision and consistency. As a result, we secured a long-term partnership and became the sole supplier of engine block castings for their flagship models.

Case Study 2: Construction Equipment Supplier

A construction equipment supplier needed a reliable source of iron castings for their heavy-duty excavator components. They had previously experienced quality issues with a different supplier and were hesitant to repeat the same mistake.

Upon receiving samples from Castimoo, they were impressed by the quality and durability of our castings. The sample evaluation process allowed them to verify that our castings met their stringent requirements for dimensional accuracy and material strength. This gave them the confidence to place a substantial bulk order, and we have since become their preferred supplier for iron castings, contributing to the success of their equipment.

These case studies highlight how the sample evaluation process can serve as a catalyst for building trust and long-term partnerships in the manufacturing industry.

How Castimoo Ensures Sample Accuracy

Ensuring that samples accurately represent the quality and characteristics of bulk production is a top priority at Castimoo. Here are some of the key methods and technologies we employ to guarantee sample accuracy:

1. Precision Casting Techniques

Our experienced technicians use precision casting techniques to create samples that closely mimic the final product. This includes using the same molds, materials, and processes that will be used in bulk production.

2. Advanced Quality Control

Our quality control team employs advanced testing and inspection methods to verify the quality of each sample. This includes dimensional checks, non-destructive testing (NDT), and material analysis.

3. Prototyping and Simulation

Before casting the samples, we often create prototypes and conduct simulations to fine-tune the design and casting parameters. This iterative process ensures that the samples meet your exact specifications.

4. Dedicated Sample Team

We have a dedicated team responsible for sample preparation and evaluation. Their expertise in crafting and inspecting samples contributes to the accuracy of the evaluation process.

5. Transparent Documentation

We provide detailed documentation and reports for each sample, including material certificates, inspection results, and photographs. This transparency allows you to make informed decisions based on concrete data.

Our commitment to precision and accuracy in sample preparation is a testament to our dedication to quality assurance.

Addressing Common Concerns and Questions

We understand that, as a customer, you may have specific concerns and questions when it comes to requesting samples before bulk orders. Let’s address some of the common ones:

1. Is there an additional cost for sample evaluation?

While there may be some nominal costs associated with sample production and shipping, these costs are typically minimal compared to the potential savings and risk mitigation benefits. Castimoo is committed to providing competitive pricing for both samples and bulk orders.

2. How long does the sample evaluation process take?

The duration of the sample evaluation process can vary depending on factors such as the complexity of the casting and your specific requirements. However, we strive to expedite this process to ensure that you can make timely decisions.

3. What if I have design changes after evaluating the samples?

We understand that design refinements may be necessary after evaluating the samples. We work collaboratively with our customers to accommodate such changes and ensure that the final product aligns with your updated specifications.

4. Can I request samples for different casting options?

Yes, you can request samples for different casting options to explore various design possibilities and materials. We are flexible and can provide samples for different configurations to help you make an informed choice.

5. Are there any quantity limitations for sample requests?

We can accommodate sample requests for a wide range of quantities, from a single sample to a small batch. Our goal is to meet your specific needs and preferences.

6. What if I have specific material requirements or certifications?

Castimoo is well-equipped to meet specific material requirements and provide the necessary certifications to ensure compliance with industry standards and regulations.

Testimonials and Success Stories

The best way to understand the impact of sample evaluation is to hear from our satisfied customers. Here are a few testimonials and success stories that showcase the value of this practice:

Testimonial 1

“Castimoo’s sample evaluation process was a game-changer for our business. We needed precision-crafted iron castings for our specialized machinery, and the samples they provided exceeded our expectations. This level of confidence allowed us to streamline our supply chain and reduce downtime significantly.”

Testimonial 2

“As an aerospace manufacturer, precision and quality are paramount for us. Castimoo’s dedication to providing accurate and reliable samples helped us ensure that our iron castings met the stringent standards of the aerospace industry. Their attention to detail and commitment to quality assurance set them apart.”

Success Story

“We were on the lookout for a new iron casting supplier, but past experiences had left us skeptical. Castimoo’s willingness to provide samples gave us the reassurance we needed. Not only did the samples meet our requirements, but their team also collaborated with us to make design improvements that enhanced the overall performance of our equipment. It’s been a win-win partnership ever since.”

These testimonials and success stories emphasize the transformative effect of sample evaluation on businesses across various industries.

Conclusion – Partnering for Quality

In the world of iron casting, quality isn’t just a buzzword—it’s the foundation upon which successful projects and businesses are built. At Castimoo, we understand the critical role that quality plays in your operations, and we’re committed to delivering iron castings that meet and exceed your expectations.

The practice of providing samples before bulk orders is not merely a service; it’s a testament to our dedication to transparency, precision, and customer satisfaction. It’s a tangible demonstration of our promise to deliver iron castings of the highest quality.

So, the next time you’re considering an iron casting project, remember the power of sample evaluation. It’s your gateway to risk reduction, confidence in quality, and the peace of mind that comes from partnering with a manufacturer who prioritizes your success.

Call to Action (CTA)

Ready to experience the difference that sample evaluation can make in your iron casting projects? Contact Castimoo today to discuss your requirements, request samples, and embark on a journey toward unparalleled quality and reliability. Your success is our mission.