Introduction

In the world of manufacturing and industrial production, sourcing the right materials is a crucial decision that can significantly impact the quality, cost, and efficiency of your products. When it comes to iron castings, businesses have various options, but two regions often stand out: China and Southeast Asia.

Castimoo, a trusted Chinese iron casting supplier, invites you on a journey to explore the advantages and disadvantages of sourcing iron castings from China compared to sourcing from Southeast Asian countries like Vietnam and Malaysia. This comprehensive guide will help you make informed decisions that align with your business needs and goals.

1. The Advantages of Sourcing Iron Castings from China

1.1. Quality and Expertise

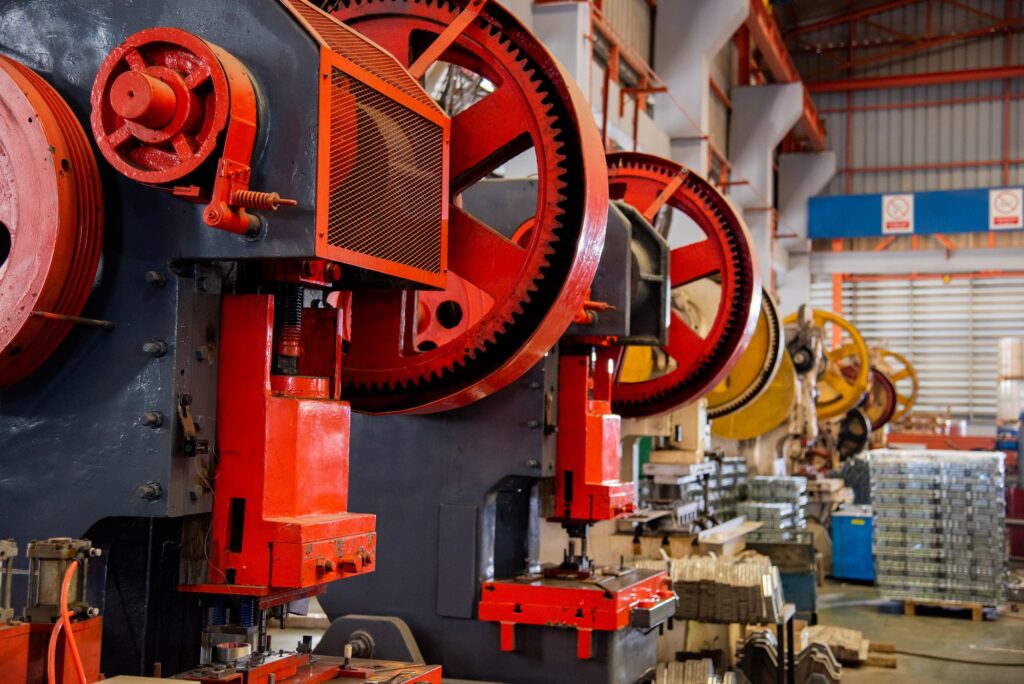

China has a rich history in the art of iron casting, dating back thousands of years. This heritage has cultivated a highly skilled and experienced workforce in the country’s iron casting industry.

Chinese foundries have mastered the craft and developed high-quality standards that are on par with international expectations. When you source iron castings from China, you can benefit from this deep pool of expertise.

The quality assurance processes in Chinese foundries are rigorous, ensuring that the finished products meet stringent quality standards. This commitment to quality is vital for industries where precision and durability are paramount.

1.2. Cost Efficiency

China’s iron casting industry enjoys significant economies of scale and efficiency in production processes. Large-scale production, combined with advanced manufacturing techniques, allows Chinese suppliers to offer competitive pricing. Whether you need standardized components or custom-designed castings, China can often provide cost-efficient solutions.

The cost savings extend to both labor and raw materials. While labor costs have risen in recent years, they are still relatively lower compared to many Western countries, making China an attractive choice for cost-conscious businesses.

1.3. Diverse Product Range

One of the advantages of sourcing iron castings from China is the vast array of products and capabilities available. Chinese foundries can cater to a wide range of casting requirements, from basic components to highly specialized, custom products. Whether you’re in the automotive, construction, or any other industry, you can find a reliable supplier in China to meet your specific needs.

Additionally, the versatility of Chinese manufacturers can be a valuable asset for businesses with evolving requirements. As your projects change and grow, having a supplier with a diverse product range can simplify your sourcing process.

1.4. Complete Industrial Supply Chain

A key advantage of sourcing iron castings from China is the completeness of its industrial supply chain. China has a well-established infrastructure that encompasses every stage of the casting process. This includes access to raw materials, state-of-the-art foundries, precision machining capabilities, and finishing processes.

Having all these elements within reach creates a seamless and integrated production process. It reduces lead times and minimizes the risks associated with coordinating various suppliers in different locations. This completeness is a testament to China’s commitment to maintaining a competitive edge in the global manufacturing landscape.

2. The Advantages of Sourcing Iron Castings from Southeast Asian Countries

2.1. Competitive Labor Costs

Countries in Southeast Asia, such as Vietnam and Malaysia, offer competitive labor costs, making them attractive destinations for businesses looking to reduce production expenses. The availability of skilled labor in these regions can further enhance their appeal. Many workers in Southeast Asian countries have experience in the manufacturing industry, making it easier to find qualified personnel for your projects.

2.2. Proximity to Key Markets

One of the strategic advantages of sourcing iron castings from Southeast Asian countries is their proximity to key markets. For businesses with a significant customer base in Asia, such as Japan, being closer to these markets can lead to shorter lead times and reduced shipping costs. This can translate into faster delivery and potentially lower logistics expenses.

2.3. Favorable Trade Agreements

Several Southeast Asian countries have established trade agreements and incentives to attract foreign businesses. These agreements can lead to reduced import/export tariffs and facilitate smoother trade processes. For companies seeking cost-effective solutions and simplified international transactions, these agreements can be a significant advantage.

3. Disadvantages of Sourcing Iron Castings from China

3.1. Language and Communication Barriers

While China’s iron casting industry is renowned for its quality and efficiency, language and communication can sometimes pose challenges. Dealing with suppliers who speak a different language can lead to misunderstandings and miscommunications. However, many Chinese suppliers have recognized this issue and employ multilingual staff or work with international clients to bridge the gap.

To overcome language barriers, it’s essential to establish clear communication channels, provide detailed specifications, and maintain open lines of dialogue with your Chinese suppliers.

3.2. Longer Lead Times

Sourcing iron castings from China may result in longer lead times compared to local suppliers. International shipping and customs processes can introduce delays, especially if not managed effectively. Businesses must factor in these lead times when planning production schedules and order quantities.

To minimize lead time challenges, consider working closely with your Chinese supplier to optimize shipping logistics and explore air or sea freight options for time-sensitive projects.

3.3. Intellectual Property Concerns

Intellectual property (IP) protection can be a concern when sourcing from China. While the country has made strides in strengthening IP laws and regulations, instances of IP infringement still occur. It’s crucial for businesses to take proactive steps to protect their designs and technology when working with Chinese suppliers. This may involve legal safeguards, non-disclosure agreements, and vigilant monitoring of production processes.

4. Disadvantages of Sourcing Iron Castings from Southeast Asian Countries

4.1. Limited Product Range

One limitation of sourcing from Southeast Asian countries is the relatively limited product range and capabilities of some suppliers. While these countries excel in certain areas, they may not offer the same diversity as Chinese manufacturers. This can pose challenges for businesses with highly specialized or complex casting requirements.

To address this limitation, businesses can consider a hybrid approach, where they source standard components from Southeast Asian suppliers and partner with Chinese manufacturers for custom or specialized castings.

4.2. Quality Assurance

Quality control and assurance can be a concern in some Southeast Asian regions. While many suppliers maintain high standards, others may not have the same level of quality control processes in place. Businesses must carefully vet potential suppliers, conduct quality audits, and establish clear quality specifications to ensure consistent product quality.

4.3. Political and Economic Stability

Political and economic stability can vary among Southeast Asian countries. Some regions may experience political unrest or economic fluctuations, which can disrupt the supply chain. It’s essential for businesses to consider these factors when choosing a sourcing destination and have contingency plans in place to mitigate potential risks.

Conclusion

In the world of iron casting sourcing, both China and Southeast Asia offer distinct advantages and disadvantages. Understanding these factors and aligning them with your business needs and priorities is essential for making informed decisions.

China, with its rich history in iron casting, quality expertise, cost efficiency, and complete industrial chain, remains a formidable choice for many businesses. The country’s ability to provide a wide range of products and integrated production processes adds to its appeal.

On the other hand, Southeast Asian countries offer competitive labor costs, proximity to key markets, and favorable trade agreements. These advantages can be particularly attractive to businesses with specific logistical and cost considerations.

Ultimately, the choice between China and Southeast Asia as a sourcing destination for iron castings depends on your unique requirements, industry, and long-term strategy. Castimoo, as a trusted Chinese iron casting supplier, is here to assist you in navigating these complexities and delivering high-quality solutions tailored to your needs.

Call to Action

If you’re ready to explore iron casting solutions that align with your business goals, we invite you to reach out to Castimoo. Our team of experts is committed to providing guidance and delivering top-tier iron casting products. Contact us today to start a partnership that enhances your manufacturing capabilities and drives your business forward.

Thank you for your time and interest in this comprehensive comparison of iron casting sourcing options. We look forward to serving your iron casting needs and helping you achieve excellence in your projects.