Introduction

As a reputable Chinese iron casting supplier, we understand the importance of managing costs in iron casting production. Whether you’re catering to the China domestic market or exporting to countries like the USA, Japan, Europe, and beyond, optimizing your budget can significantly impact your bottom line.

In this article, we will break down the costs associated with iron casting production and provide valuable insights on how you can effectively manage your budget.

The Basics of Iron Casting Production

Iron casting is a complex process that involves several stages, each contributing to the overall costs. The process typically includes pattern making, mold preparation, melting and pouring, cooling and solidification, shakeout, and finishing.

Each stage requires meticulous attention to detail and skilled labor to ensure high-quality castings. Understanding the significance of each stage is crucial for cost optimization.

Factors Influencing Iron Casting Production Costs

To effectively manage your budget, it’s important to identify and analyze the factors that influence iron casting production costs. Here are some key factors to consider:

Raw Materials

The choice of raw materials significantly impacts production costs. The quality and type of materials, such as pig iron, scrap metal, or alloys, can affect both the initial material cost and subsequent processing costs. Selecting suitable materials that meet the required specifications while considering their cost-effectiveness is essential.

Design Complexity

Intricate and complex designs require more time, effort, and resources to produce. Design intricacies often translate into increased material consumption, longer production cycles, and additional machining or finishing processes. Simplifying designs without compromising quality can lead to cost savings without affecting the functionality of the final product.

Production Volume

Economies of scale play a vital role in iron casting production costs. Producing larger quantities generally results in lower per-unit costs due to better resource utilization and reduced setup and tooling costs. By optimizing production volume, you can take advantage of economies of scale and minimize costs.

Equipment and Technology

Investing in advanced machinery and technology can optimize costs in the long run. Modern equipment offers greater efficiency, accuracy, and productivity, reducing labor requirements and minimizing errors. Upgrading your production facilities with state-of-the-art technology can lead to cost savings and improved overall performance.

Labor

Skilled labor is a crucial component of iron casting production. Highly skilled workers can ensure superior quality and efficiency, but they may come at a higher cost. Optimizing labor costs involves finding the right balance between skilled labor and automation, streamlining processes, and providing adequate training and support to enhance productivity.

Identifying Cost-saving Opportunities

To optimize your iron casting production budget, consider implementing the following strategies:

Material Selection

Collaborate with material suppliers to select cost-effective materials without compromising quality. Conduct thorough research and compare prices, ensuring that the selected materials meet the required specifications and quality standards. Additionally, consider recycling or reusing scrap materials whenever possible to reduce waste and lower costs.

Design Optimization

Collaborate closely with designers and engineers to simplify complex designs. By reducing unnecessary intricacies, you can minimize material consumption, shorten production cycles, and reduce finishing requirements. Emphasize functionality and practicality while maintaining the desired aesthetic appeal.

Process Streamlining

Analyze each stage of the iron casting process to identify areas for improvement. Streamline the workflow, eliminate bottlenecks, and minimize non-value-added activities. Adopt lean manufacturing principles to optimize production efficiency, reduce waste, and enhance overall productivity. Implementing process improvements can have a significant impact on cost reduction.

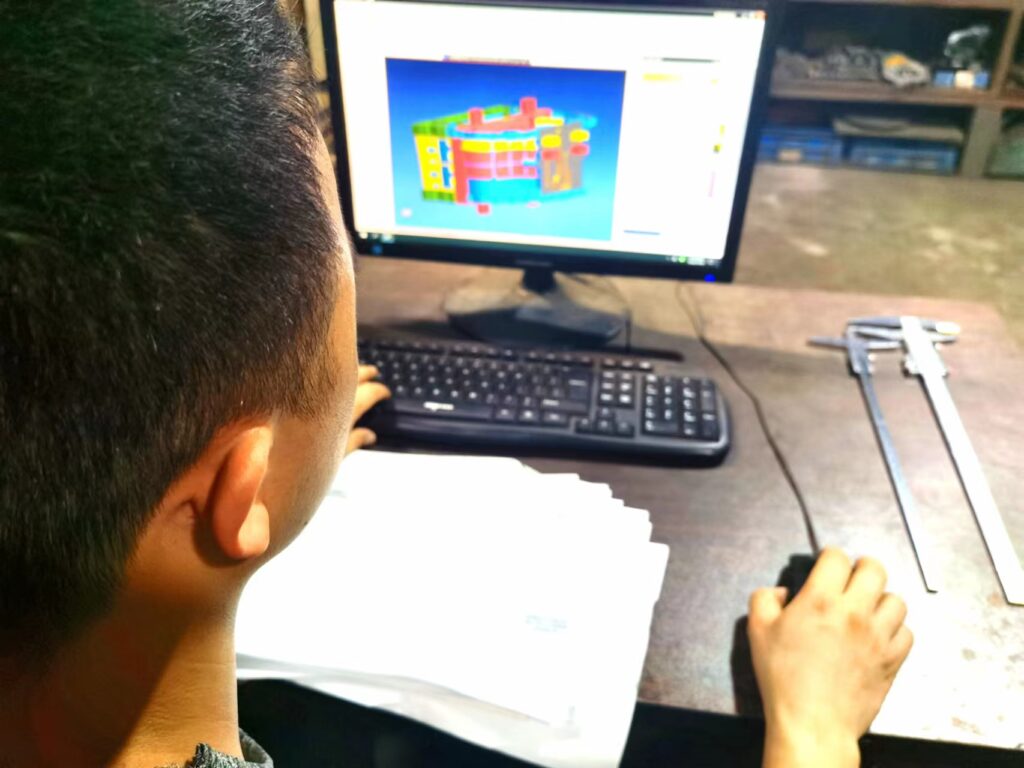

Automation and Technology

Evaluate opportunities to introduce automation and advanced technology into your production processes. Automated systems can increase productivity, minimize human error, and reduce labor costs. Invest in technologies such as computer-aided design (CAD), computer-aided manufacturing (CAM), and robotic systems to streamline operations and improve efficiency.

Supplier Selection

Choosing the right suppliers is essential for cost optimization. Research and identify reliable suppliers who offer competitive pricing, high-quality materials, and excellent customer service. Establish long-term relationships with trusted suppliers to negotiate favorable pricing agreements and ensure a consistent supply chain.

Case Studies

To illustrate the effectiveness of cost-saving measures in iron casting production, consider the following case studies:

Case Study 1: Company X reduced their iron casting production costs by 15% by optimizing their material selection and streamlining their manufacturing processes. By collaborating with suppliers to source cost-effective materials and implementing lean manufacturing principles, they achieved significant cost savings without compromising quality.

Case Study 2: Company Y improved their cost-efficiency by investing in advanced technology and automation. By incorporating robotics and advanced machinery into their production line, they achieved higher productivity, reduced labor costs, and minimized errors. As a result, their iron casting production costs decreased by 20%.

Conclusion

Understanding and effectively managing the costs of iron casting production is crucial for optimizing your budget. By considering factors such as raw materials, design complexity, production volume, equipment and technology, and labor, businesses can identify cost-saving opportunities. Implementing strategies such as material selection, design optimization, process streamlining, automation and technology, and supplier selection can lead to significant cost reductions. By optimizing your iron casting production budget, you can enhance your competitiveness, improve profitability, and deliver high-quality products to your customers.

Call-to-Action

We are Castimoo, an iron casting supplier in China. We specialize in custom gray and ductile iron castings for over 30 years. Contact us today to learn more about our high-quality iron casting products and how we can help you optimize your budget. Visit our website or reach out to our team for a personalized quote or further information.

One Response

I like this web site because so much utile stuff on here : D.