Introduction

At Castimoo, we understand that choosing the right metal casting process for your project is a critical decision. Whether you are in China, the USA, Japan, Europe, or any other part of the world, the success of your project largely depends on selecting the most suitable casting method.

In this comprehensive guide, we will walk you through the essential steps to make an informed decision when it comes to metal casting. From understanding your project’s unique requirements to exploring various casting processes and ensuring quality control, this article covers it all.

Understanding Your Project Requirements

The first and most crucial step in selecting the right metal casting process is understanding your project’s specific requirements. To do this effectively, you need to consider the following factors:

a. Materials

The choice of materials is fundamental in metal casting. Different materials possess distinct properties, such as strength, durability, and corrosion resistance. Consider the following:

Steel: Known for its strength, steel is often used in applications where durability is paramount.

Aluminum: Lightweight and corrosion-resistant, aluminum is ideal for various industries, including automotive and aerospace.

Iron: Cast iron offers excellent wear resistance and is commonly used in heavy machinery and engine components.

The material you select will have a significant impact on the overall performance of your project. Ensure that you choose a material that aligns with your project’s specific needs.

b. Design

The design of your component or product plays a critical role in determining the casting process. Features like wall thickness, undercuts, and draft angles must be considered. A well-thought-out design ensures that the casting process is both efficient and cost-effective.

c. Quantity

The volume of components you need can also influence your casting process choice. For small quantities, rapid prototyping methods like investment casting might be appropriate. On the other hand, high-volume production often favors die casting or sand casting.

Exploring Different Metal Casting Processes

Once you have a clear understanding of your project requirements, it’s time to explore the various metal casting processes available. Each process has its own advantages and limitations. Let’s take a closer look at some of the most common casting methods:

a. Sand Casting

Advantages: Suitable for both small and large parts.

Versatile and cost-effective for low to medium production runs.

Minimal tooling and equipment costs.

Limitations: Surface finish is not as smooth as other methods.

Tolerances may not be as tight.

b. Investment Casting (Precision Casting)

Advantages: Excellent surface finish and intricate detail.

Suitable for small to medium production runs.

Ideal for complex geometries.

Limitations: Longer production cycle compared to other methods.

Higher per-unit cost for large quantities.

c. Die Casting

Advantages: High production rates for large quantities.

Precise and repeatable results.

Excellent surface finish.

Limitations: Higher tooling and equipment costs.

Limited to specific alloys.

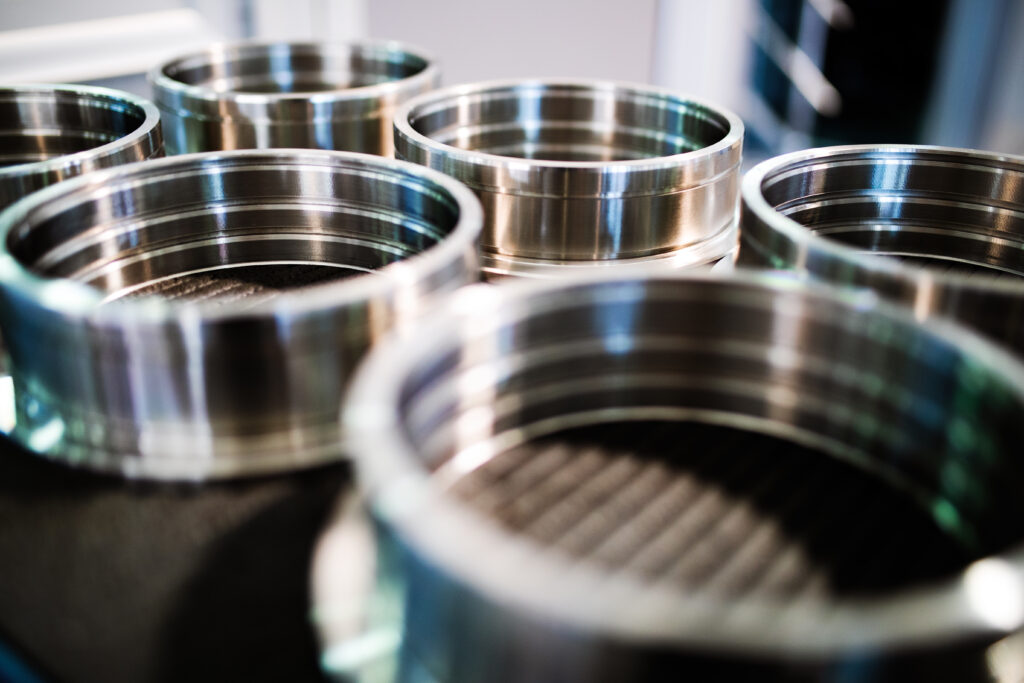

d. Centrifugal Casting

Advantages: Suitable for cylindrical and symmetrical parts.

High density and minimal defects.

Limitations: Limited to specific shapes.

Not ideal for complex geometries.

e. Continuous Casting

Advantages: Efficient for producing long, continuous lengths of metal.

High quality and consistent results.

Limitations: Limited to specific applications like metal sheets, rods, and pipes.

Not suitable for complex parts.

Each of these casting methods has its own set of advantages and limitations. Your choice should be based on your project’s unique requirements and goals.

Material Selection: Choosing the Right Alloy

Selecting the appropriate metal alloy is paramount in the metal casting process. The alloy you choose should align with your project’s specific requirements. Here are some considerations for various alloys:

a. Steel Alloys

Steel is a versatile material known for its strength and durability. It is commonly used in industries that require robust components. Different steel alloys have varying properties, such as:

Carbon Steel: Offers high strength and is cost-effective.

Stainless Steel: Resistant to corrosion, making it ideal for marine and food industry applications.

Alloy Steel: Enhanced strength and hardness, suitable for demanding applications.

The selection of a steel alloy depends on your project’s requirements, including strength, corrosion resistance, and cost constraints.

b. Aluminum Alloys

Aluminum is a lightweight, corrosion-resistant material that finds applications in various industries. Some common aluminum alloys include:

6061 Aluminum: Known for its general-purpose strength and corrosion resistance.

7075 Aluminum: Offers high strength, ideal for aerospace and high-stress applications.

A380 Aluminum: Excellent castability and heat resistance, suitable for die casting.

Consider the specific characteristics of each aluminum alloy to determine which one suits your project best.

c. Iron Alloys

Iron alloys, such as gray iron and ductile iron, are commonly used in heavy machinery, engine components, and construction equipment. Key considerations when choosing iron alloys include:

Gray Iron: Provides good wear resistance and is ideal for applications with heavy loads.

Ductile Iron: Known for its ductility and impact resistance, making it suitable for automotive and machinery components.

Understanding the properties and advantages of different iron alloys is essential for making the right selection.

Design Considerations for Casting

The design of your component or product has a significant impact on the success of the casting process. When designing for casting, consider the following factors:

a. Wall Thickness

Optimal wall thickness is essential for ensuring successful metal casting. Thick walls may lead to defects, while thin walls may not provide adequate strength. Striking the right balance is key.

b. Draft Angles

Incorporating draft angles into your design allows for easy removal of the casting from the mold. Without draft angles, the casting can become stuck, leading to defects and complications.

c. Fillets and Radii

Smooth transitions between surfaces, especially in sharp corners, help prevent stress concentrations and potential defects.

d. Undercuts

Minimize or eliminate undercuts in your design to simplify the casting process. Undercuts can make it challenging to remove the casting from the mold.

e. Filtration and Feeding Systems

Consider the placement of gates and runners to facilitate the flow of molten metal and reduce the risk of defects.

f. Tolerances

Specify appropriate tolerances for your design to ensure the casting meets your project’s requirements. Tighter tolerances may require additional processing.

To design effectively for casting, it’s crucial to work closely with experienced engineers and pattern makers who understand the intricacies of the casting process.

Cost and Efficiency Factors

Cost and efficiency considerations are integral to selecting the right casting process. Balancing cost-effectiveness with the required quality and production efficiency is essential.

a. Tooling and Equipment Costs

Different casting processes may require specific tooling and equipment. Evaluate the upfront costs associated with each process and consider factors like mold setup, maintenance, and replacement.

b. Material Costs

The cost of the material, especially in larger production runs, can significantly impact the overall project budget. Consider the cost per unit and the overall project cost when choosing the material.

c. Labor Costs

Labor costs are a significant part of any manufacturing process. Consider the skill level and number of personnel required for the chosen casting method.

d. Production Efficiency

Consider the production rate of the chosen casting process. High-volume production runs may favor processes like die casting, while low-volume runs might benefit from investment casting or sand casting.

e. Lead Times

Evaluate the lead times associated with each casting process. Some methods may offer shorter lead times, while others may require longer production cycles.

It’s important to strike a balance between cost, efficiency, and quality when making your casting process decision. Remember that a well-planned approach can often yield significant long-term cost savings.

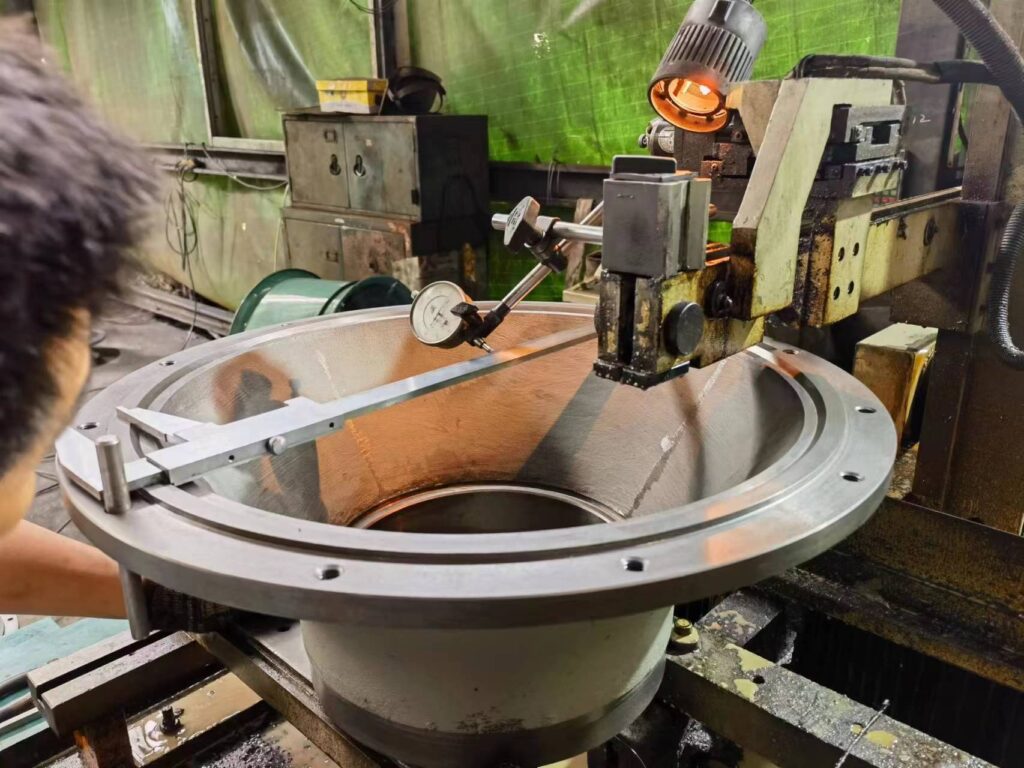

Quality Control and Testing

Quality control is a critical aspect of the metal casting process. Ensuring the integrity of your cast components is essential for the success of your project. Here are key elements of quality control:

a. Inspection and Testing

Regular inspection and testing during the casting process help identify defects and discrepancies early. Non-destructive testing methods, such as X-rays, ultrasonic testing, and magnetic particle testing, can provide valuable insights into the quality of your castings.

b. Dimensional Accuracy

Maintaining tight tolerances and dimensional accuracy is crucial to meeting your project’s specifications. Coordinate measuring machines (CMMs) are often used to ensure precise dimensions.

c. Surface Finish

The surface finish of your cast components can impact their aesthetics and performance. Polishing, shot blasting, and other finishing techniques can enhance the surface quality.

d. Material Testing

Material testing, including tensile testing, hardness testing, and impact testing, is essential to verify the mechanical properties of your castings.

Quality control measures should be established and maintained throughout the casting process. This ensures that any defects are identified and addressed promptly.

Environmental Considerations

In today’s world, environmental considerations are paramount. The metal casting industry has made significant strides in adopting eco-friendly practices. When selecting a casting process, consider the environmental impact and sustainability:

a. Energy Efficiency

Some casting methods are more energy-efficient than others. Evaluate the energy consumption of the chosen process and consider greener alternatives.

b. Waste Reduction

Efforts to minimize waste, such as recycling sand in sand casting or optimizing gating systems to reduce scrap, can contribute to a more sustainable casting process.

c. Emissions

Consider the emissions generated by the casting process. Modern foundries employ technologies to reduce emissions and minimize their environmental footprint.

d. Sustainable Materials

Some materials used in metal casting may be more sustainable than others. Explore the use of recycled or sustainable materials when possible.

By considering these environmental factors, you can make a positive contribution to sustainability while meeting your project’s needs.

Case Studies

Let’s explore some real-world case studies where the right metal casting process selection led to successful outcomes:

a. Aerospace Component

In a project requiring lightweight, high-strength components for aerospace applications, the choice of precision investment casting proved ideal. The intricate geometries and tight tolerances were easily achievable, resulting in components that met the stringent requirements of the aerospace industry.

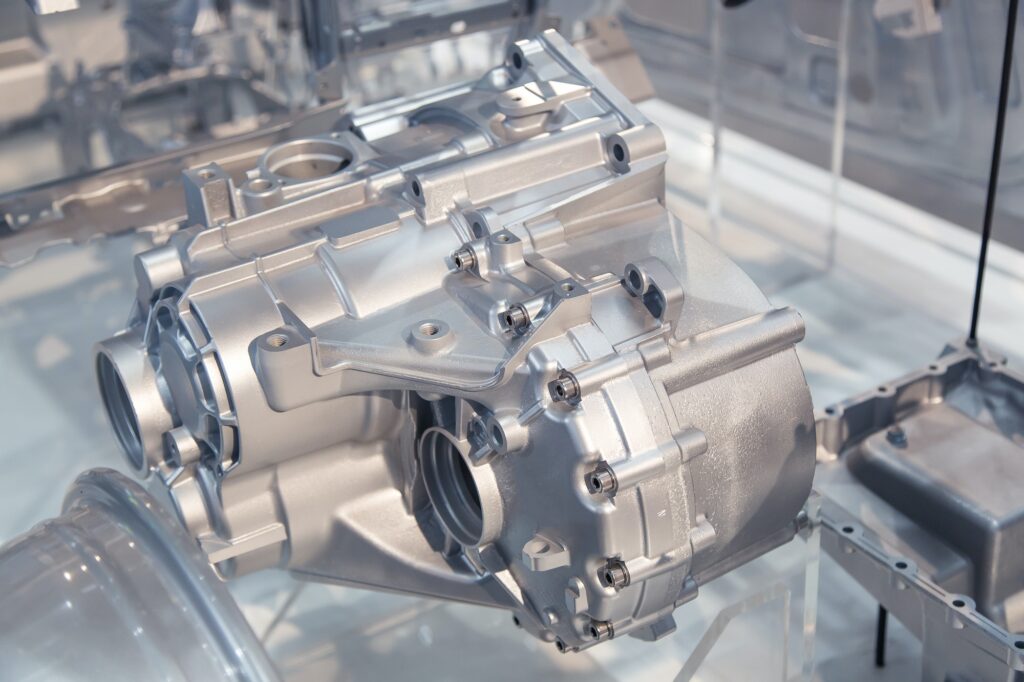

b. Automotive Transmission Housing

For a high-volume production of automotive transmission housings, die casting was the preferred choice. The die casting process allowed for the rapid production of complex parts with excellent surface finishes. The efficiency and cost-effectiveness of this method made it the perfect solution for this automotive project.

c. Architectural Ironwork

A project involving intricate and ornate ironwork for architectural purposes required the use of sand casting. The sand casting method allowed for the production of customized, artistic designs with excellent detail. This project exemplified the versatility of sand casting for decorative and ornamental applications.

d. Pump Casings

In the manufacturing of pump casings, ductile iron casting was chosen due to its combination of strength and corrosion resistance. The ductile iron casings proved highly durable and cost-effective for applications where high reliability was crucial.

These case studies demonstrate how the right casting process can lead to success in a wide range of applications. By carefully analyzing your project requirements and considering various casting methods, you can achieve outstanding results.

Conclusion

Selecting the right metal casting process is a critical decision that can significantly impact the success of your project. It involves a comprehensive evaluation of your project’s requirements, the exploration of different casting processes, and considerations related to materials, design, cost, quality control, and sustainability.

At Castimoo, we are committed to helping you make informed decisions when it comes to metal casting. Whether your project is in China, the USA, Japan, Europe, or any other part of the world, we are here to provide expert guidance and support throughout the entire casting process.

We understand that each project is unique, and our experienced team is dedicated to delivering the highest quality cast components that meet your specific requirements. Contact us today to discuss your project, and let us help you choose the right metal casting process for your success.

Call to Action

Ready to start your project with Castimoo? Contact us today for expert guidance on selecting the right metal casting process. Our team of experienced professionals is here to assist you every step of the way.