Introduction

In today’s dynamic global market, the demand for high-quality iron casting products is soaring. Manufacturers like Castimoo have risen to the challenge, supplying bespoke iron casting solutions to clients across China, the USA, Japan, Europe, and beyond. A defining hallmark that distinguishes a reputable iron casting supplier is their unwavering commitment to providing comprehensive documentation, including material certificates and inspection reports.

In this comprehensive article, we will delve into the profound significance of these documents in upholding regulatory compliance, fostering customer trust, and fortifying Castimoo’s position as an industry leader.

1. The Vital Role of Material Certificates

Material certificates stand as testament to the integrity and quality of iron casting products. These certificates, often accompanied by a unique identification number, offer a detailed breakdown of the composition and origin of materials used in the casting process. By tracing the material’s journey from raw form to final product, material certificates provide invaluable insights into the manufacturing process.

1.1 Defining Material Certificates

Material certificates, also known as mill test reports or material test certificates, offer a comprehensive overview of the materials used in iron casting. These certificates include details such as chemical composition, mechanical properties, heat treatment, and more.

1.2 Enhancing Traceability

The traceability of materials is crucial for quality control and regulatory compliance. Material certificates offer a verifiable trail, ensuring that the materials used align with specified requirements and standards. This is particularly significant when catering to different regulatory demands across various markets.

1.3 Meeting Regulatory Requirements

Material certificates serve as a bridge between iron casting manufacturers and regulatory bodies. They provide the necessary documentation to demonstrate compliance with international and regional standards, ensuring that the produced components meet safety and quality benchmarks.

1.4 Building Customer Confidence

Transparency is a cornerstone of customer satisfaction. By providing material certificates, Castimoo empowers clients to make informed decisions. The availability of these certificates enhances trust, reassuring clients that the products they receive adhere to stringent quality control measures.

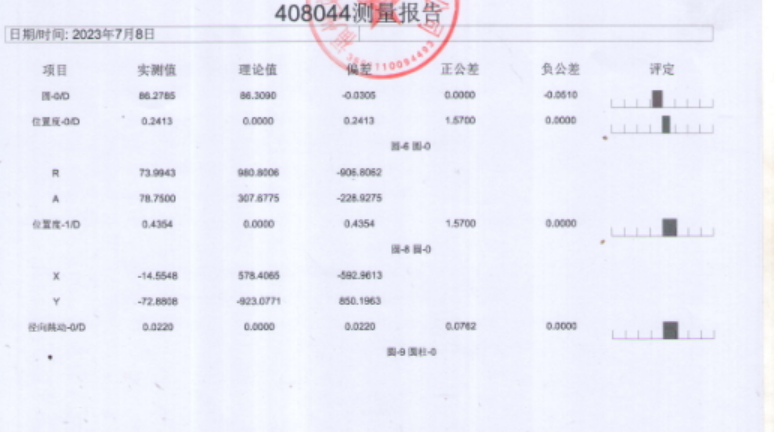

2. The Weighty Significance of Inspection Reports

Inspection reports contribute significantly to the quality assurance process, verifying that iron casting products meet predetermined specifications. These reports, generated after rigorous testing, provide an objective evaluation of product attributes and performance.

2.1 Unveiling Inspection Reports

Inspection reports encapsulate the outcomes of comprehensive assessments conducted during and after the iron casting process. These assessments cover dimensions, tolerances, surface finish, mechanical properties, and more.

2.2 Ensuring Product Quality

Quality is the cornerstone of Castimoo’s operations. Inspection reports play a pivotal role in verifying that iron casting products align with predefined quality benchmarks, offering a tangible demonstration of adherence to excellence.

2.3 Complying with Industry Regulations

Iron casting is subject to stringent industry regulations and guidelines. Inspection reports serve as a mechanism to ensure compliance, as they substantiate that products meet safety and performance criteria set forth by regulatory bodies.

2.4 Fortifying Product Reliability

The longevity and dependability of iron casting products hinge on consistent quality. Regular inspections, accompanied by detailed reports, bolster the reliability of Castimoo’s offerings, translating into sustained customer satisfaction.

3. Navigating Global Regulatory Requirements

The diverse international markets served by Castimoo bring with them a tapestry of regulatory expectations. Successfully navigating these multifaceted requirements is a testament to Castimoo’s adaptability and commitment to quality.

3.1 Market-Specific Regulations

Different regions boast distinct regulations and standards governing iron casting products. From China to the USA, Japan to Europe, Castimoo’s ability to harmonize its practices with varying expectations is integral to its global success.

3.2 Overcoming Compliance Challenges

Addressing the challenges presented by diverse regulatory landscapes requires meticulous planning and execution. Castimoo’s strategic approach ensures seamless adherence, assuring clients of products that meet and exceed legal stipulations.

3.3 Bridging Cultural and Legal Disparities

Cultural nuances and legal disparities can pose hurdles in the realm of international business. Castimoo’s proficiency in navigating these complexities underscores its commitment to building enduring partnerships on the bedrock of mutual respect and compliance.

4. Castimoo’s Pledge to Regulatory Compliance

Castimoo’s dedication to regulatory compliance is a cornerstone of its brand identity. This commitment is evident across every facet of its operations, fostering transparency, accountability, and client satisfaction.

4.1 A Transparent Approach

Castimoo’s emphasis on transparency extends beyond the casting process. The provision of accurate material certificates and detailed inspection reports exemplifies its pledge to openness, allowing clients to make informed decisions.

4.2 Customer-Centric Philosophy

Customers lie at the heart of Castimoo’s operations. The availability of material certificates and inspection reports aligns with Castimoo’s customer-centric ethos, instilling confidence and solidifying long-term relationships.

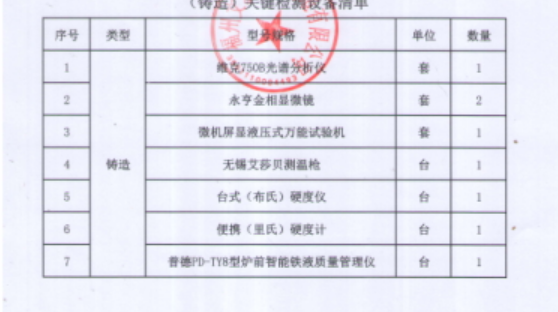

4.3 Quality Assurance Ecosystem

Regulatory compliance is intertwined with quality assurance. Castimoo’s ecosystem of quality control measures, including inspections and documentation, engenders products that are as reliable as they are compliant.

5. Paving the Way Forward: Future of Regulatory Compliance in Iron Casting

As the iron casting landscape continues to evolve, the future of regulatory compliance holds intriguing prospects. Castimoo’s proactive stance positions it to seize emerging opportunities and surmount challenges that lie ahead.

5.1 Anticipating Industry Trends

The iron casting industry is witness to constant innovation. Castimoo’s vigilant monitoring of industry trends enables it to stay ahead of the curve, evolving its compliance practices to align with the changing terrain.

5.2 Technological Advancements

Digitalization and technological advancements are reshaping manufacturing paradigms. Castimoo’s exploration of advanced tracking methods and digitized documentation heralds a future where compliance is seamlessly integrated into the production process.

5.3 Upholding Excellence

Castimoo’s dedication to regulatory compliance is unwavering. By adapting to evolving regulatory landscapes and embracing cutting-edge technologies, Castimoo is poised to maintain its reputation as a trusted iron casting supplier.

Conclusion

In the complex realm of iron casting, regulatory compliance is an irreplaceable linchpin. Castimoo’s steadfast commitment to providing accurate material certificates and comprehensive inspection reports underscores its mission to deliver products of unparalleled quality.

As the industry continues its forward march, Castimoo’s vigilance, adaptability, and customer-centric approach will undoubtedly pave the way for a future where regulatory compliance and excellence stand hand in hand. Through transparency, accountability, and unwavering dedication, Castimoo has etched its mark as a true champion in the realm of iron casting.