Introduction

Iron castings play a crucial role in various industries worldwide, offering a multitude of applications and benefits. With their versatility, durability, and cost-effectiveness, iron castings have become a preferred choice for manufacturers in diverse sectors.

In this article, we will delve into the wide-ranging applications of iron castings and explore the industries that heavily rely on them. By understanding the versatility of iron castings, we can appreciate their significance and impact on numerous sectors.

Understanding Iron Castings

Iron castings are products formed by pouring molten iron into molds and allowing it to solidify into the desired shape. This casting process provides several advantages, including cost-effectiveness, design flexibility, and exceptional durability. By manipulating the composition and structure of the iron, manufacturers can create iron castings with specific properties suitable for different applications.

Gray iron, ductile iron, and white iron are commonly used types of iron in casting processes, each offering unique characteristics that cater to various industry requirements. The exceptional strength, heat resistance, and machinability of iron castings make them a superior choice compared to other materials.

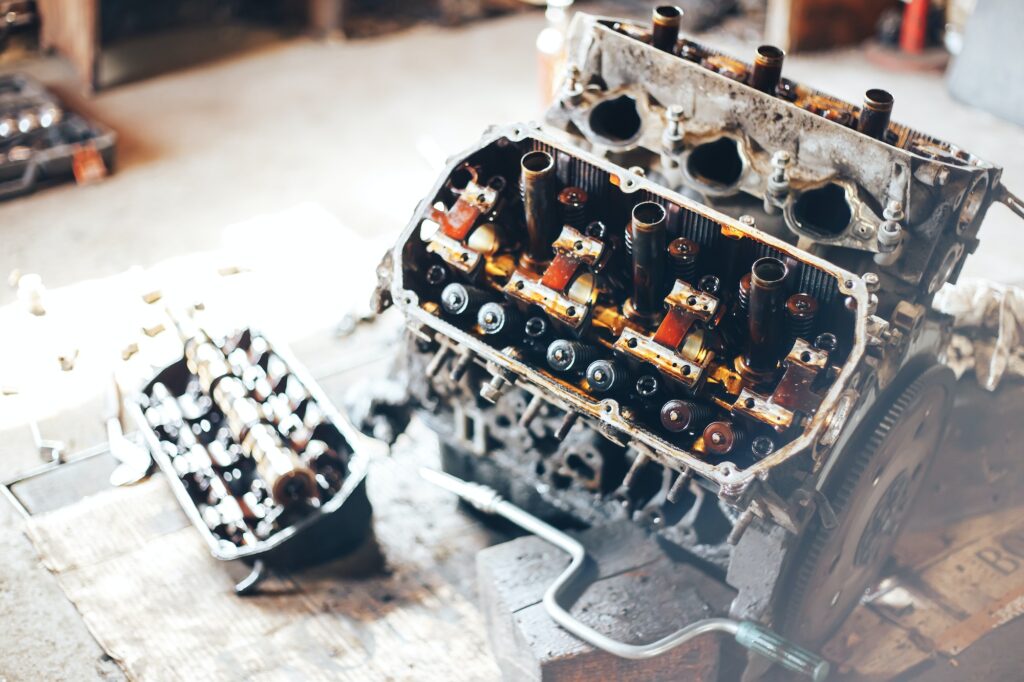

Automotive Industry Applications

The automotive industry heavily relies on iron castings for numerous components. Engine blocks, transmission cases, brake components, and suspension parts are just a few examples of critical applications of iron castings in vehicles.

Iron castings excel in automotive manufacturing due to their ability to withstand high temperatures, absorb vibrations, and provide structural integrity. The superior strength of iron castings ensures the longevity and reliability of automotive components, contributing to the overall performance and safety of vehicles.

Construction and Infrastructure Applications

In the construction and infrastructure sectors, iron castings find extensive use in various applications. Manhole covers, pipes, drainage systems, and architectural components are commonly made from iron castings.

Iron castings excel in these applications due to their load-bearing capacity, corrosion resistance, and longevity. They provide robust solutions for infrastructure development, ensuring the durability and safety of structures. Iron castings are especially valuable in environments where exposure to heavy loads, extreme weather conditions, and corrosive substances is a concern.

Machinery and Equipment Applications

Iron castings are essential in machinery and equipment manufacturing, finding application in diverse industries. Machine frames, gears, pulleys, and agricultural machinery components heavily rely on iron castings.

The versatility and strength of iron castings contribute to the performance and reliability of machinery. These castings provide stability, wear resistance, and the ability to handle heavy loads, making them indispensable for a wide range of equipment across industries.

Energy and Power Industry Applications

The energy and power sectors also benefit significantly from the use of iron castings. Wind turbines, power generation plants, and transmission systems utilize iron castings in various components.

Iron castings excel in these industries due to their ability to withstand extreme conditions, dissipate heat, and maintain structural integrity. They play a crucial role in ensuring the efficiency and reliability of energy production and distribution systems.

Other Industries and Miscellaneous Applications

Apart from the aforementioned industries, iron castings find applications in several other sectors as well. In the defense and military industries, iron castings are vital for manufacturing tanks, armored vehicles, artillery, and ammunition components. The strength, protection, and reliability offered by iron castings make them indispensable for these applications.

Iron castings also play a significant role in the mining and quarrying industry, where heavy machinery components like crusher parts, conveyor systems, and mineral processing equipment require robust materials. With their ability to withstand harsh conditions and heavy-duty requirements, iron castings contribute to the efficiency and safety of mining operations.

Additionally, the oil and gas industry relies on iron castings for producing valves, pumps, pipelines, and drilling equipment. Iron castings offer corrosion resistance, high-pressure capabilities, and the ability to handle demanding environments in this sector.

Conclusion

The versatility of iron castings across industries is truly remarkable. From automotive manufacturing and construction to machinery, energy, and other sectors, iron castings continue to be the material of choice for a wide range of applications. The unique properties of iron castings, including strength, durability, and cost-effectiveness, make them an indispensable solution for numerous industries.

When selecting an iron casting supplier, it is crucial to prioritize reliability and quality to ensure the best results for specific requirements. As we have explored the diverse applications and industries that rely on iron castings, it is evident that their versatility and widespread use will continue to play a vital role in shaping various sectors across the globe.

Choosing a Reliable Iron Casting Supplier

When it comes to harnessing the full potential of iron castings for your industry, it is crucial to partner with a reliable and experienced iron casting supplier. The quality of iron castings directly impacts the performance, durability, and safety of your products or projects. Here are a few key factors to consider when choosing an iron casting supplier:

Expertise and Experience

Look for a supplier with a proven track record in iron casting manufacturing. A supplier with extensive experience and expertise can better understand your specific requirements and deliver high-quality castings that meet your standards.

Quality Assurance

Ensure that the supplier follows strict quality control processes to guarantee the integrity of their iron castings. They should have certifications and adhere to industry standards to provide you with castings that meet or exceed your expectations.

Customization and Flexibility

Every industry and application has unique requirements. A reliable supplier should be able to offer customized solutions tailored to your specific needs. They should have the capability to handle complex designs, provide flexibility in production quantities, and accommodate any necessary modifications.

Timely Delivery

Time is often a critical factor in industrial projects. Choose a supplier that can meet your deadlines and provide timely delivery of iron castings without compromising on quality.

Excellent Customer Support

A reputable supplier values customer satisfaction and provides exceptional support throughout the process. They should be responsive to your queries, offer technical assistance when needed, and maintain clear communication throughout the project.

Call to Action

Ready to explore the versatility of iron castings for your industry? Contact us at Castimoo, your trusted iron casting supplier, today. With our extensive experience, commitment to quality, and dedication to customer satisfaction, we can provide you with top-notch iron castings that meet your specific requirements. Visit our website or reach out to our knowledgeable team to discuss your project and discover how iron castings can elevate your products and projects to new heights.