Introduction

Custom iron castings play a pivotal role in various industries, providing durable and versatile solutions for complex projects. When it comes to meeting unique requirements, custom iron castings offer unparalleled flexibility and innovation. In this article, we will explore the world of custom iron castings and how they can address your specific needs with their innovative solutions.

Understanding Custom Iron Castings

Custom iron castings are metal components created through a meticulous process that involves designing, pattern making, molding, and casting. These castings are tailored to match individual project specifications, offering a level of precision and customization that standard options cannot match.

The Custom Iron Casting Process

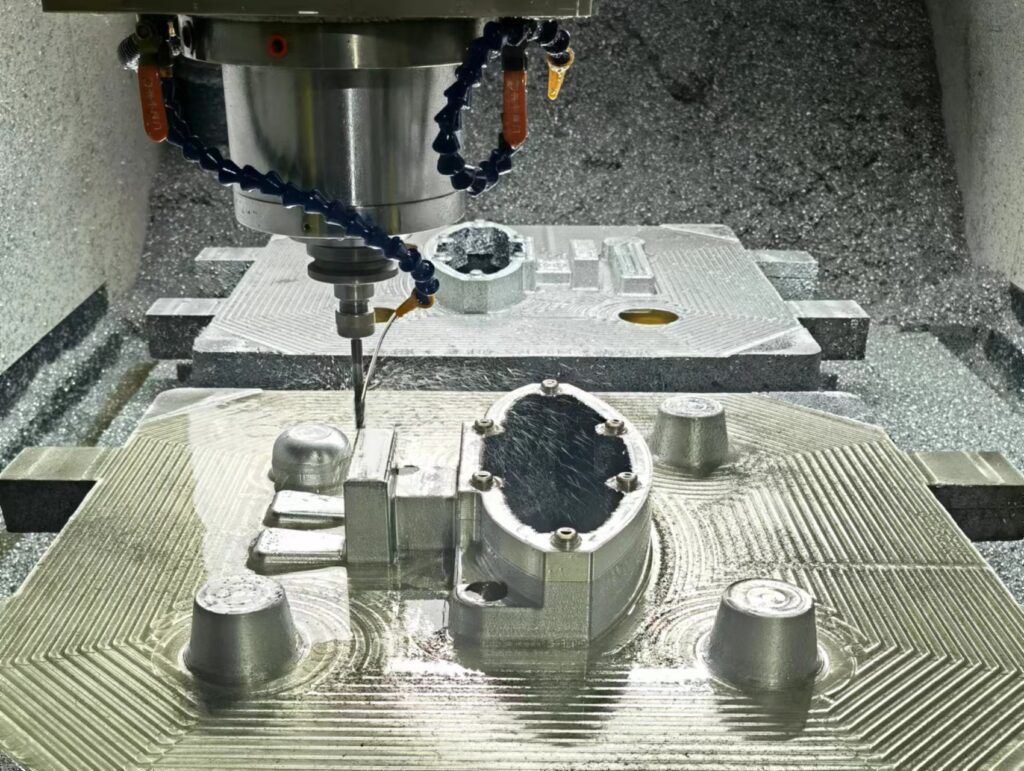

Design: The custom iron casting process begins with the design phase. Skilled engineers work closely with clients to understand their unique requirements, including desired shapes, dimensions, and material specifications. Advanced computer-aided design (CAD) software is used to create detailed 3D models of the casting.

Pattern Making: Once the design is finalized, patterns are created. Patterns are replicas of the final casting that are used to create the molds. Skilled pattern makers craft patterns using various materials such as wood, plastic, or metal. The patterns are precisely constructed to capture all the intricate details of the casting.

Molding: The next step is molding, where the patterns are used to create molds. Molds can be made from different materials, such as sand, ceramic, or shell. The pattern is placed inside the mold cavity, and the molding material is packed around it to create a negative impression of the casting.

Melting and Casting: Once the mold is ready, the casting process begins. Molten iron is prepared by melting iron in a furnace at high temperatures. The molten iron is then poured into the mold cavity, allowing it to fill the void left by the pattern. As the iron cools and solidifies, it takes the shape of the desired casting.

Cooling and Solidification: After the molten iron is poured into the mold, it undergoes a cooling and solidification process. As the iron cools, it transitions from a liquid to a solid state, forming the final shape of the casting. Proper cooling and solidification are critical to ensure the desired mechanical properties and dimensional accuracy of the casting.

Finishing: Once the casting has cooled and solidified, it undergoes various finishing operations. These operations may include removing excess material, trimming, grinding, sandblasting, shot blasting, and heat treatment processes like annealing, quenching, or tempering. Finishing operations ensure the casting meets the required specifications and surface finish standards.

Quality Control: Throughout the custom iron casting process, strict quality control measures are implemented. Inspections and tests are conducted at various stages, including pattern inspection, mold inspection, casting inspection, and finishing inspection. Non-destructive testing methods such as visual inspection, X-ray, ultrasonic testing, or magnetic particle inspection may be used to ensure the integrity and quality of the castings.

Delivery: Once the custom iron castings pass all quality checks, they are ready for delivery. The castings are carefully packaged to prevent damage during transit and shipped to the customer’s location. The supplier ensures timely and efficient delivery to meet project deadlines.

The entire process of custom iron casting requires skilled craftsmanship, advanced technology, and meticulous attention to detail. It is a collaborative effort between the client and the iron casting supplier to achieve the desired results.

By understanding the intricacies of the custom iron casting process, clients can appreciate the craftsmanship involved and have confidence in the quality and precision of the final castings.

Advantages of Custom Iron Castings

The advantages of choosing custom iron castings are numerous. First and foremost, their design flexibility allows for the creation of intricate shapes and sizes, enabling you to bring your unique vision to life.

Additionally, custom iron castings offer exceptional material strength, ensuring durability and reliability in demanding applications. Moreover, their cost-effectiveness and scalability make them a viable choice for projects of all sizes.

Applications of Custom Iron Castings

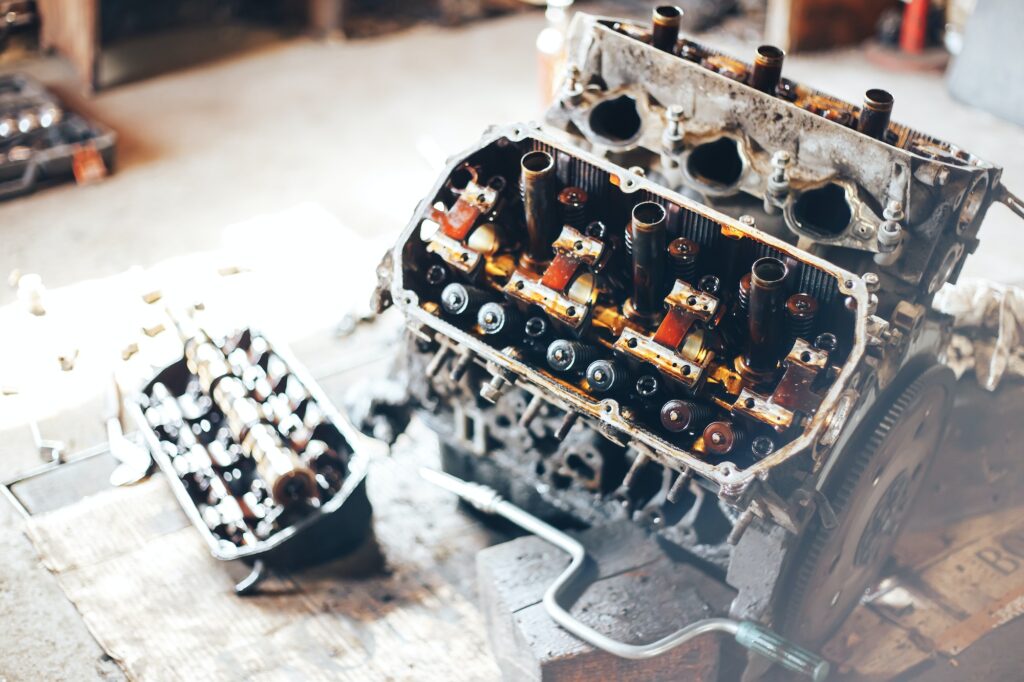

Custom iron castings find applications across a wide range of industries. In the automotive sector, they are utilized in engine components and structural parts. In the machinery industry, custom iron castings form the backbone of heavy equipment and machinery. Similarly, construction, agriculture, and many other sectors benefit from the versatility and strength of custom iron castings.

Meeting Unique Requirements

One of the standout features of custom iron castings is their ability to meet unique and specific project requirements. Whether it’s an unusual shape, a specific alloy composition, or a challenging design, custom iron castings can accommodate your needs. Collaborating closely with an iron casting supplier, you can discuss your requirements and tap into their expertise to develop tailored solutions that precisely match your project specifications.

Collaboration and Consultation

Successful implementation of custom iron castings relies on effective collaboration between the customer and the iron casting supplier. Through consultations, you can communicate your project’s unique requirements and constraints, allowing the supplier to provide expert guidance and recommendations. This collaborative approach ensures that the resulting custom iron castings not only meet your expectations but exceed them.

Quality Assurance and Precision

Custom iron castings undergo rigorous quality control measures to ensure precision and adherence to specifications. Advanced technologies and techniques are employed to guarantee accurate dimensions, surface finishes, and material properties. Look for suppliers with appropriate certifications and a track record of delivering high-quality custom iron castings.

Case Studies or Customer Testimonials

Real-life examples and customer testimonials highlight the success stories of using custom iron castings. These case studies demonstrate how custom iron castings have solved specific challenges and met unique requirements. By showcasing successful projects, you can gain insights into the possibilities that custom iron castings offer for your own ventures.

Conclusion

When it comes to addressing unique requirements, custom iron castings emerge as an innovative solution that offers unmatched flexibility, durability, and precision. By collaborating with an experienced iron casting supplier, you can harness the potential of custom iron castings to elevate your projects to new heights. Embrace the world of custom iron castings and discover the endless possibilities they bring to your industry.

Call-to-Action

We are Castimoo. Over 30 years of experience for gray iron casting and ductile iron casting. We have customized over 1000 kinds of iron casting products for domestic and overseas (including USA, France, Japan) customers.

To explore the innovative solutions of custom iron castings for your unique requirements, visit our website www.castimoo.com or contact us today. Our team of experts is ready to assist you in realizing your vision with precision-engineered custom iron castings.