Introduction

Iron casting has been a crucial component of industrial manufacturing for centuries. It has been used to create everything from machinery parts to household items. However, as technology advances and the demands of consumers change, the future of iron casting is looking to be an exciting one. In this blog post, we will explore the trends and innovations that are shaping the future of iron casting.

Green Casting

One trend that is gaining traction in the iron casting industry is green casting. Green casting involves using environmentally friendly materials and processes to create iron castings. The use of green sand, which is a type of sand that is made from natural materials, is a popular choice for green casting.

Green sand is not only more environmentally friendly than traditional sand, but it is also more cost-effective. In addition to green sand, other materials like water-based binders and organic additives are used to make green castings.

Green casting is gaining popularity due to its reduced carbon footprint and the fact that it produces less waste. As consumers become more environmentally conscious, the demand for products that are made using sustainable materials and processes is growing. Green casting is poised to become a major trend in the iron casting industry in the coming years.

Automation

Another trend that is shaping the future of iron casting is automation. Automation involves using machines and robots to perform tasks that were traditionally done by humans.

In the iron casting industry, automation is being used to improve efficiency and reduce costs. Automation can also improve safety in the workplace by reducing the number of workers needed to perform dangerous tasks.

One area where automation is being used in the iron casting industry is in the molding process. Automated molding machines can create molds more quickly and accurately than humans can. This can result in a higher quality product and faster production times. In addition, automation is being used in the finishing process to reduce the time and labor required to finish castings.

3D Printing

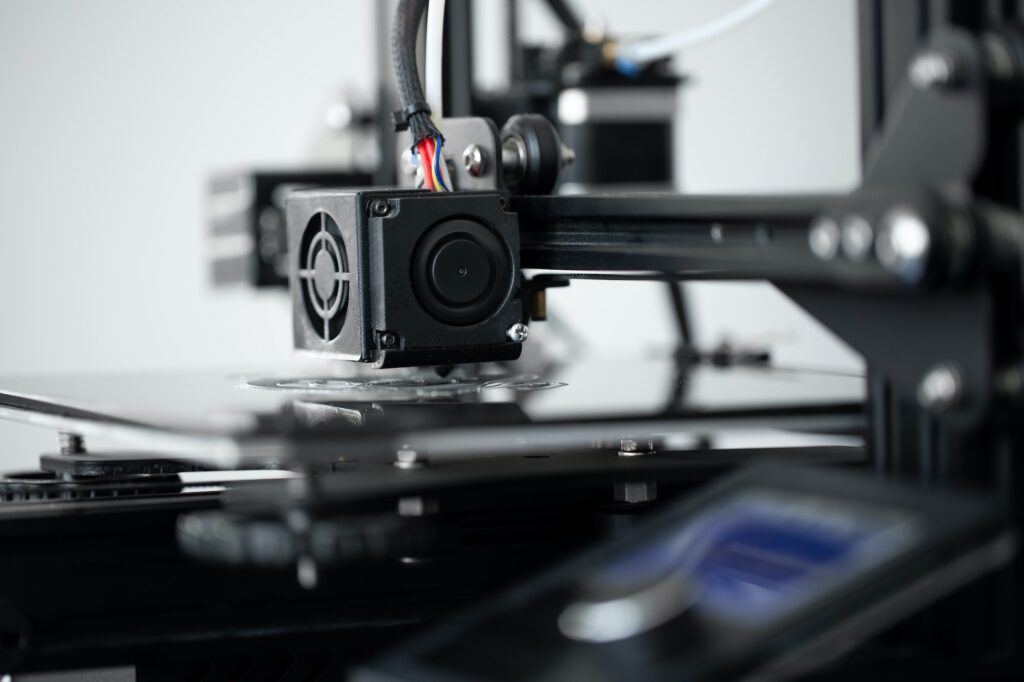

3D printing is a technology that is already being used in a variety of industries, including aerospace, automotive, and medical. It involves creating three-dimensional objects from digital designs.

In the iron casting industry, 3D printing is being used to create patterns for molds. This can reduce the time and cost associated with traditional pattern-making methods.

3D printing is also being used to create sand molds for iron castings. The use of 3D printed molds can result in a more accurate and consistent product. In addition, 3D printing can reduce waste by only creating the necessary amount of sand for each mold.

Simulation Software

Simulation software is another trend that is shaping the future of iron casting. Simulation software allows manufacturers to create virtual models of their products and test them in a simulated environment. This can help manufacturers identify and correct design flaws before physical production begins.

In the iron casting industry, simulation software is being used to optimize the casting process. By simulating the casting process, manufacturers can identify potential defects and make adjustments before production begins. This can result in a higher quality product and reduced costs associated with rework and scrap.

Alloy Development

Finally, alloy development is another trend that is shaping the future of iron casting. Alloy development involves creating new combinations of metals to improve the properties of iron castings.

By creating alloys that are stronger, lighter, or more corrosion-resistant, manufacturers can create products that meet the changing needs of consumers.

One area where alloy development is being used in the iron casting industry is in the automotive sector. The demand for lighter, more fuel-efficient vehicles is driving the development of new alloys that can withstand the high temperatures and stresses of modern engines.

In addition, alloy development is being used to create castings for renewable energy applications, such as wind turbines and solar panels.

Conclusion

This article we discussed the future of the casting industry from the five aspects of green casting, automation, 3D printing, simulation software and alloy development together. The future of iron casting is looking bright. With the continuous development of new technologies, the future of the casting industry will enter a new era, worthy of our expectations.

We are Castimoo, a supplier dedicated to the production of ductile iron and gray cast iron. We have more than 30 years of experience in the casting industry. We are very willing to discuss with you the design and production of iron castings, and hope we can be your partner in your business and bring you more benefits.