Introduction

Iron casting is a standard production process for various industrial parts and components. Iron casting is a reliable and cost-effective way of producing high-quality parts for multiple industries, from construction equipment to automobile parts.

Choosing a reliable iron casting supplier should be distinct from selecting a source for industrial equipment or office supplies. While some might consider machined iron casting a commodity, it is far from it, and choosing the right source for a specific application needs careful analysis.

In this blog post, we will introduce you how to identify the reliable iron casting suppliers through some aspects. We believe that we can bring you valuable references for your purchasing projects.

The most significant aspect of the purchasing process is supplier qualification. Traditionally, the primary duty of a purchaser was to identify a qualified, responsive, and reliable iron casting supplier. In certain circumstances, buyers assumed that any supplier willing to meet the purchase criteria contractually was qualified. On the other hand, using low-cost and unqualified suppliers can result in high quality and save time and money in the long run.

Factors To Consider When Choosing A Reliable Iron Casting Supplier

When choosing a reliable iron casting supplier to get iron castings for your manufacturing project or another purpose, the following factors should be considered.

Review the most critical factors when looking for a reliable iron casting supplier!

- Supplier Reliability of Casting Products

Locating and working with a reliable and experienced iron casting supplier is critical. Ideally, customers should pick a few iron casting suppliers and review their product/service portfolios to understand their specializations and strengths thoroughly. Information on the high quality standards maintained, the required manufacturing capacity, turnaround times, and customer support service must also be requested.

Also, a customer should request past job references and suggestions from the iron casting products supplier. Doing business with a company with relevant experience is always a good option. Whenever iron castings are required, it must be verified that the cast iron foundries can design them. Before the buyer makes a purchasing decision, any questions about delivery timelines, transportation expenses, casting gradation, and other associated issues must be entirely handled.

- Expertise in the Industry and Market Reputation

It is critical to recognize that iron casting goods are different from other types of mechanical equipment. These iron casting products must be created to meet the needs of the underlying applications, which highlights the need to collaborate with an iron casting supplier with extensive industry knowledge.

A top iron casting supplier is familiar with the various customer requirements and the potential challenges that the latter may encounter when using iron casting products. It is usually preferable to engage with an iron casting supplier who fully understands the nature of the requirements and provides solutions accordingly.

The necessity to be able to choose and use a reliable and quality-assured iron casting supplier is critical for improving overall performance and efficiency. Demand for iron casting products is steadily increasing in line with global trends. Choosing a reliable iron casting source is simple; keeping these considerations in mind will assist consumers in picking the most reliable iron casting company.

- Production Capacity

Production capacity is essential when looking for a reliable iron casting supplier. The supplier’s production capacity should align with your business requirements to ensure they can meet your demand for iron casting components. Seek a supplier with the production capability to handle your requests on schedule.

A reliable supplier should have current equipment and technologies to produce high quality iron casting parts efficiently. Consider the supplier’s lead and turnaround timeframes as well. A supplier who can deliver components fast will help you keep your production schedule constant and prevent downtime. A supplier with a flexible production capacity can also add value to their clients.

They should be able to scale up or down production based on your company’s needs without sacrificing high quality. You can ensure that you obtain high-quality iron casting components consistently and on schedule by selecting a supplier with a manufacturing capacity that matches your company’s requirements.

- The Supplier’s Quality Control

Because quality is always the most significant concern for both the iron casting supplier and the consumer, the buyer must evaluate the iron casting suppliers’ high quality control capacity. You may assess this point by discussing quality issues with iron casting suppliers.

This will allow you to determine whether the iron casting supplier is professional and whether they have suitable inspection techniques for material high quality, dimensions, and faults, among other things.

- Diversity In Process

Businesses aim to sell their products, and some iron casting suppliers only offer one casting method. For example, a company solely using the investment casting technique will try to convince you that it is the best option for your application.

But what if using the metal casting technique is the most incredible option for you and your requirements? Instead, look for an iron casting supplier who provides a variety of casting procedures so that the best solution for YOU is chosen.

If your components have a variety of designs, applications, and sizes, the ideal iron casting technique is likely to be different for each part. If having a single source for all of your iron casting needs is crucial, a reputable iron casting supplier should have a wide range of capabilities. Combined with other integrated capabilities, this can aid in simplifying and compressing the supply base.

- Testing and Certification

Is it necessary for your application for the iron casting supplier to have proper certifications, such as ISO 9001 or TS 16949, indicating that they have implemented quality control systems? If this is the case, ensure that your reliable iron casting supplier has the necessary certifications.

True, a reputable iron casting supplier could go through the process of obtaining the required certifications, but time is likely off their side. Most trustworthy metal casting suppliers will show their credentials on their websites, and companies can be searched by accreditation. Be careful.

Is non-destructive testing (NDT), mechanical testing, or chemical testing required? While all grey iron castings vendors can outsource any necessary testing, some have all of those skills in-house, which can save time and money. If your application does not necessitate testing, a reliable iron casting supplier specializing in high compliance work with in-house skills might not be the best match.

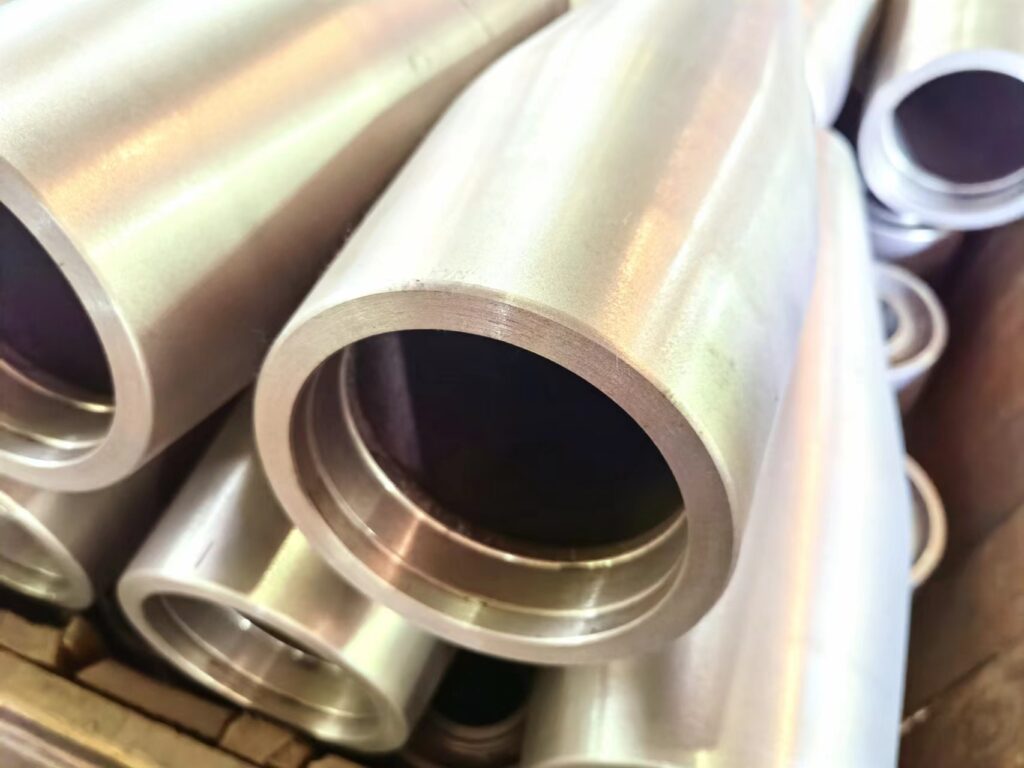

- Capabilities for Machining

Customers are increasingly looking for iron casting suppliers with machining skills. If faults are found during machining, this can help to avoid disputes. When a third party is machining, it may lead to “finger-pointing” regarding who is to blame.

Is it a problem with the iron castings or with the machining? If the iron casting supplier discovers an issue during machining, the problem is rectified sooner, and there is no argument about who is to blame.

Because the cast iron foundries “owns it,” processing, shipping, handling, and replacement take less time. Whether a problem exists, integrated machining simplifies the supply chain by reducing handling time and shipping costs before the product reaches the consumer.

- Mechanical Testing

Do you want an iron casting supplier who can review your material selection and suggest how to help your products last longer or save money? Iron casting companies may excel at delivering a product to specification but have limited other capabilities. Some will go above and beyond the letter of the Rules to save you time and money.

Do you have specifications for both ferrous and non-ferrous iron casting? Some cast iron foundries have restricted or specialized capabilities. To avoid the need for several suppliers, ensure that a reliable iron casting supplier can meet all of your material or alloy requirements.

- Product Delivery Capability

The iron casting supplier you choose should be able to supply the required items within the timeframes you specify. Any consumer’s two most significant concerns are timely delivery and cast iron quality – and the iron casting supplier should match these expectations.

You may also inquire about the mould design procedures used by casting manufacturers supplier. Check that the molds have the proper thickness and robust matching surfaces. Learn about the materials used in mould design. Many best iron casting manufacturers suppliers use rapid prototyping to speed up manufacturing. Simulations and performance analyses should be performed in-house as needed.

Ensure that quality checks are performed at each level. Seek a reliable iron casting supplier who also serves as an expert in a firm. That way, you can be confident that your machining needs will be met quickly and expertly. Enquire about the metal alloys used in gray iron castings. To eliminate doubts, a good list of deliverables should be provided.

When it comes to iron casting applications, safety is of the utmost importance. To keep the dangers of unforeseen mishaps and downtimes, you should inquire about the safety requirements of the items. Visit the company’s manufacturing facility if at all possible. This will allow you to assess the supplier’s skills accurately.

- Visit Their Facilities

What better approach to assess whether someone is the reliable iron casting supplier than to take a plant tour? Most cast iron casting manufacturers will gladly have you as a guest to gain your business. If you have any reservations about their operations, capability, or culture by the end of the trip, there are probably better suppliers for you.

- Customization and Flexibility

When selecting an iron casting supplier, flexibility and customization are critical. A reliable supplier should be able to manufacture items to your exact requirements and be willing to work with you to make changes as needed. They should be able to create pieces in various shapes, sizes, and materials as required.

When assessing a supplier’s flexibility and customization capabilities, inquire about their capacity to make unique parts, whether they stock a variety of materials, and whether they offer extra services such as machining or finishing.

- Costs and Estimates

Price shouldn’t be the sole consideration for suitable iron casting manufacturers. But, you must exercise caution to avoid spending more money than is necessary. Create a list of the suppliers that appear to be the best fit to provide your required answers. Compare their cast iron product portfolios, expertise industries/sectors, quality metrics, and other crucial factors.

Get a detailed quote from these businesses. The section should include a breakdown of ALL costs (and not just the price of the iron casting product). There should be no hidden costs at all. Instead of seeking a ‘cheap’ cast iron casting product supply manufacturers suppliers, look for a company that can provide total value.

Partnering with a correctly chosen manufacturers suppliers should result in a good ROI. The iron casting supplier you select should be committed to quality control, be diverse enough in its operations to service many sectors/applications, and produce the best goods at competitive prices.

Finding and employing reliable and quality-assured iron casting solutions is critical for improving overall performance and efficiency. Demand for iron casting products is steadily increasing in line with global trends. Locating a reliable iron casting manufacturer is simple; keeping these considerations in mind will assist consumers in selecting the most reliable iron casting supplier.

- A Commitment To Providing Excellent Customer Service

A reliable iron casting supplier should give outstanding customer service and keep lines of communication open with their clients. Seek a supplier who responds to your wants and concerns and will collaborate to solve any emerging problems.

Consider elements such as response times, availability, and desire to communicate when evaluating a supplier’s customer service and communication. Seek a supplier who updates you on the status of your purchase frequently and is available to answer any queries you may have.

After signing the contract, it is also critical for the reputable iron casting supplier and buyer to view each other as partners. The reliable iron casting supplier should perform as an extension of the buyer’s producing companies.

It is also critical at this time for the buyer to avoid prospecting other suppliers and instead focus on strengthening the connection with the chosen supplier. It is usually beneficial to draught an agreement with a trusted iron casting supplier indicating that quick delivery is part of the contract and that he will supply the desired quality castings at the previously negotiated fee.

Questions You Should Consider

- Is the supplier familiar with your products and markets?

- Can the supplier meet several of your gray cast iron products criteria, reducing the required vendors?

- Is there anything you value most? Is it of high quality? Price? What about customer service? Is there anything else? How do the strengths of your suppliers compare to your requirements?

- Does the supplier currently hold the necessary certifications?

- Is the supplier’s testing capability adequate?

- Do they deal with the alloys regularly?

- What further services do you require? Is this something the supplier provides?

- Is the company stable, with a solid history and a promising future?

- What are their values, and do they correspond to yours?

- Do you think your company will do business with them? Can you establish a rapport with them?

- What are the casting products offered by the supplier?

Conclusion

Iron castings are not a commodity, despite what some may think; therefore, choosing the best supplier for your particular application requires careful thought. Finding a reliable iron casting supplier needs a detailed check of various factors.

When selecting a supplier, consider the supplier’s quality, experience, manufacturing capacity, flexibility, pricing, customer service, certifications, and reputation, and ask many questions. You can ensure that you acquire high-quality machined iron casting parts that fit your standards and help your manufacturing process by researching and selecting a supplier who fulfills your needs.

We are Castimoo, specializing in the design and production of iron castings. We are able to custom produce grey cast iron and ductile iron products for you and have over 30 years of experience in this industry.

We are ISO 9001 certified. Our clients are from France, USA, Japan, etc. We have been working together for more than 10 years. They are very satisfied with our products and services. We believe that our iron casting products will bring you greater profit. Contact us now!