Introduction

Iron castings are a great choice for many different applications. They are strong, durable and can withstand a lot of wear and tear.

If your business needs high quality iron casting parts, it is important to find a supplier that can provide you with what you need.

China is a great source for these types of parts and there are many suppliers that can meet your needs.

In this article, we will discuss what are the benefits of importing iron castings from China and some things you should keep in mind when choosing a supplier.

1. What are iron castings and what are their main uses?

Iron castings are made by pouring molten iron into a mold. It is a very old process that has been used for centuries to make all kinds of objects, from tools to buildings.

Iron castings are strong and durable, making them ideal for many different applications.

Cast iron is a type of iron made from pig iron. It has a higher carbon content than other types of iron, which makes it harder and more brittle.

Iron castings can be used for a variety of applications, including:

–Engine parts. Because cast iron is durable, it can withstand high temperatures.

–Machinery parts. Cast iron is also commonly used for mechanical parts because it is strong and wear resistant.

–Construction materials. Cast iron is used to make building materials such as beams, columns and stairs.

–Fixings. Cast iron can also be used to make fixtures such as door handles and lamps.

If your business needs high quality iron castings, China is a great source. There are many casting suppliers in China that can provide you with the products and services you need.

2. What are the benefits of importing iron castings from China?

When you need high quality iron castings for your project, it is important to source from a reputable supplier.

Here are five reasons why importing iron castings from China, a country with one of the world’s leading suppliers of iron castings, can be beneficial.

- Quality castings at competitive prices

China is known for producing high quality iron castings at competitive prices. By importing iron castings from China, you get the best of both worlds – high quality parts at a fraction of the cost of buying from Western suppliers.

- A wide variety of casting options

There are a large number of foundries in China, each with its own expertise and strengths in terms of casting types as well as materials.

This means that you can find any iron casting you need in China, including specialized parts that are not easily found elsewhere.

- Fast turnaround times

Chinese suppliers are known for their fast turnaround times, often delivering orders in a matter of weeks.

This means you can get your parts faster, assemble them into your product, and quickly capture your local market. Instead of having to wait for big months to ship from other countries.

- Smooth and efficient communication

When working with a Chinese supplier, you will appreciate the smooth, efficient and professional communication channels. This will help ensure that your order runs smoothly from start to finish.

- A reliable supplier with years of experience

Last but not least, sourcing iron castings from China allows you to benefit from the years of experience that Chinese suppliers have in the field.

With a reliable supplier who has a good track record of production and delivery, you can rest assured that your order will be handled efficiently and delivered on time.

3. How to find a good iron casting supplier in China?

- Do your research

When looking for a supplier in China, it is important to do your research and compare different suppliers. Ask for samples to ensure the quality of the iron castings before you make a purchase.

- Check their qualifications

Look for a supplier that has experience producing quality iron castings and has a good reputation in the industry. Check that they are certified by a recognized organization, such as ISO 9001 or SGS.

- Consider the cost

When choosing a supplier, it is important to compare prices, but don’t forget to take the quality of the castings into account as well. If the quality of the iron castings is not good, a lower price is not necessarily the best choice.

- Production capacity

The supplier’s foundry should have the capacity to produce the number of iron castings you need. Ask the supplier to show you their production capacity to ensure they can meet your needs.

- Quality assurance procedures

The supplier’s foundry should have a strict quality assurance program to ensure the quality of their iron castings. Ask the supplier to show you their quality assurance procedures to ensure that they meet your standards.

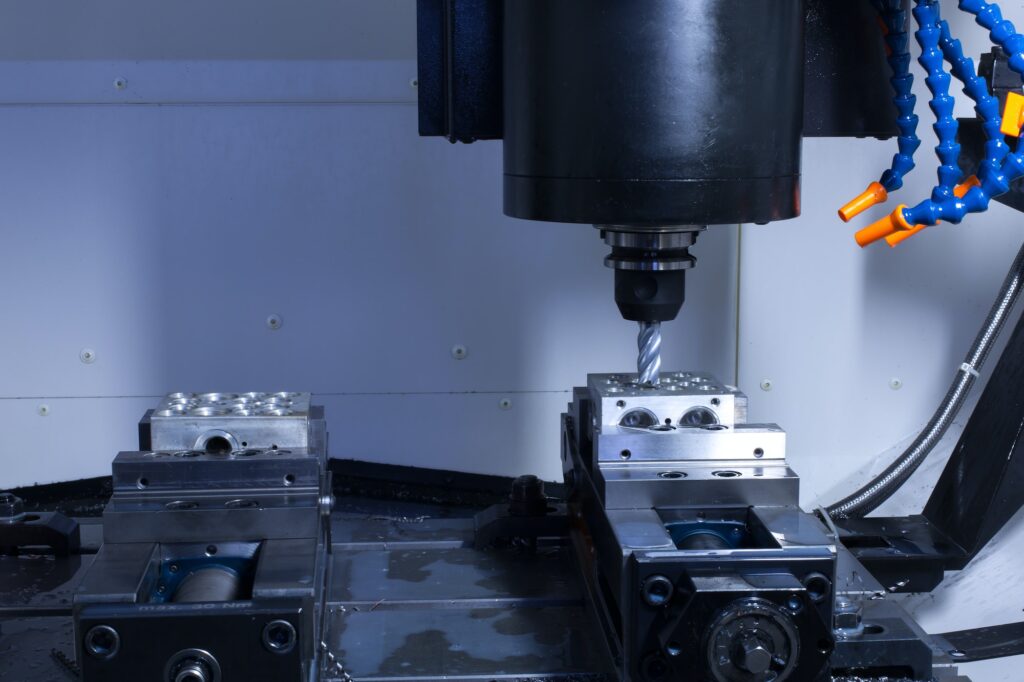

- Manufacturing Equipment

The supplier’s factory should be equipped with advanced manufacturing equipment capable of producing high quality iron castings. Ask the supplier to show you their manufacturing equipment to ensure they meet the standards.

- Staffing and training level

The supplier’s foundry should have a well-trained workforce capable of producing high quality iron castings. Ask the supplier to provide you with a roster of employees so that you can assess their qualifications.

4. What are some common mistakes people make when importing iron castings from China?

When importing iron castings from China, there are several things to keep in mind to avoid costly mistakes.

- Not verifying the quality of the castings before shipping.

This can result in parts that are defective or out of specification.

- Not verifying that the supplier has the ability to produce the casting to specification.

Some suppliers may not have the necessary equipment and experience to produce quality parts.

- Failure to verify that the supplier is qualified to produce iron castings.

China’s environmental requirements are increasing, and some non-compliant foundries are no longer qualified to continue producing castings.

If the foundry does not have an emissions permit, there are likely to be potential hazards that must be implemented.

- No procurement plan is set up in advance.

Especially during the epidemic, the impact of ship schedules is huge. Delays in ship schedules happen from time to time.

Therefore, when purchasing iron castings, please take into account the delay of shipping time as well.

- Not understanding Chinese customs and traditions.

In China, there is Lunar New Year (usually from the end of January to the beginning of February), and Chinese manufacturers usually take a half month or even a month off during this time.

Therefore, for orders during the Lunar New Year, please communicate with your suppliers to arrange production plans in advance to avoid delays.

5.Which is more advantageous, the sourcing company or the casting manufacturer?

- Purchasing company

When importing iron castings from a sourcing company, you may get a lower price point than if you import from a casting manufacturer.

This may be more than you think, due to the fact that sourcing companies have worked with factories for many years, often purchasing parts in large quantities from them, and therefore can get lower prices.

However, there are some drawbacks to importing iron casting parts in this manner. First, the quality of the parts may not be as good as if they were purchased directly from the foundry.

In addition, while the services of a sourcing company are relatively more professional, it can be difficult to find a reputable sourcing company that you can trust to provide high quality parts.

- Casting Manufacturers

Importing iron casting parts from a foundry has several advantages.

First, the quality of the parts is usually much better than if they were sourced from a sourcing company.

Second, finding a reputable casting manufacturer is usually easier than finding a reputable sourcing company.

Finally, because casting manufacturers are experts in their field, they are often able to provide customized services that a sourcing company cannot provide.

6. Tips to ensure your order arrives safely and on time

- Plan ahead

Iron castings are not always in stock, so it is important to plan your order well in advance.

- Check the quality of your suppliers

Make sure the supplier you choose is reputable and has a good track record for quality and capacity.

- Inspect parts before shipping

Once your parts are cast and shipped, they must be carefully inspected for any defects or damage.

- Use a freight forwarder

Using a freight forwarder can help ensure that your parts arrive safely and on time.

- Communicate with your suppliers

Maintain close communication with your suppliers, especially in the event of any delays or problems with your order.

7. What are the common problems that may occur during import and customs clearance and how can I avoid them?

When importing iron castings, it is important to be aware of the problems that can occur during the customs clearance process. By following these five tips, you can help ensure a smooth and hassle-free import process.

- Make sure you have the correct documentation.

Iron castings must be accompanied by a commercial invoice, packing slip and certificate of origin. If any of these documents are missing or incorrect, it can cause delays in customs clearance.

- Verify that the supplier is reputable.

Not all suppliers are reputable, and some may try to defraud importers by selling counterfeit or low-quality parts. It is important to do your research and only work with suppliers who have a good reputation and are known for producing high quality iron castings.

- Check the quantity and quality of parts before shipping.

It is important to inspect parts before shipping to ensure they meet your expectations. Any problems with the quantity and quality of the parts may cause delays in customs clearance.

- Make sure the shipping company is reliable.

If iron castings are damaged in transit, it may be difficult to file a claim with the appropriate parties. It is important to work with a reliable shipping company with a proven track record of delivering goods without damage.

- Be prepared for customs clearance delays.

Due to the complex nature of customs clearance, there is always the possibility of delays. Make sure you have enough time in your schedule to account for possible delays in receiving cast iron shipments.

Conclusion

To summarize, in this article we discussed the main uses of iron castings, the benefits of importing iron castings from China, how to find a good iron casting supplier in China, common mistakes made when importing iron castings from China, the pros and cons of sourcing companies vs. casting manufacturers, tips to ensure your order arrives safely and on time, and how to avoid common problems during the import and customs clearance process.

China is a great source channel for iron castings. Castimoo is a Chinese manufacturer of iron castings. Specializing in the design and production of gray cast iron and ductile iron parts with 30 years of experience.

Our products are exported to Japan, France, USA, etc. and are well received by foreign customers. We hope that through our experience and technology, we can also help you.