Introduction

If you’re in the market for iron castings, there’s no doubt that you’ve considered sourcing from China.

After all, China is responsible for 80% of the world’s iron casting production.

But if you’re new to sourcing in China, it can be a daunting task.

There are countless suppliers to choose from, and it can be difficult to determine which one is the right fit for your business.

In this blog post, we’ll give you 10 tips on how to source iron castings in China.

We’ll discuss consider your casting requirements, do your research, evaluate potential suppliers carefully, check whether the supplier is certified, get quotes from multiple suppliers, negotiate, place a small order first, control quality, be wary of intellectual property theft, and be patient.

By the end of this post, you’ll have a better understanding of how to source iron castings from China and be on your way to getting the best products for your business.

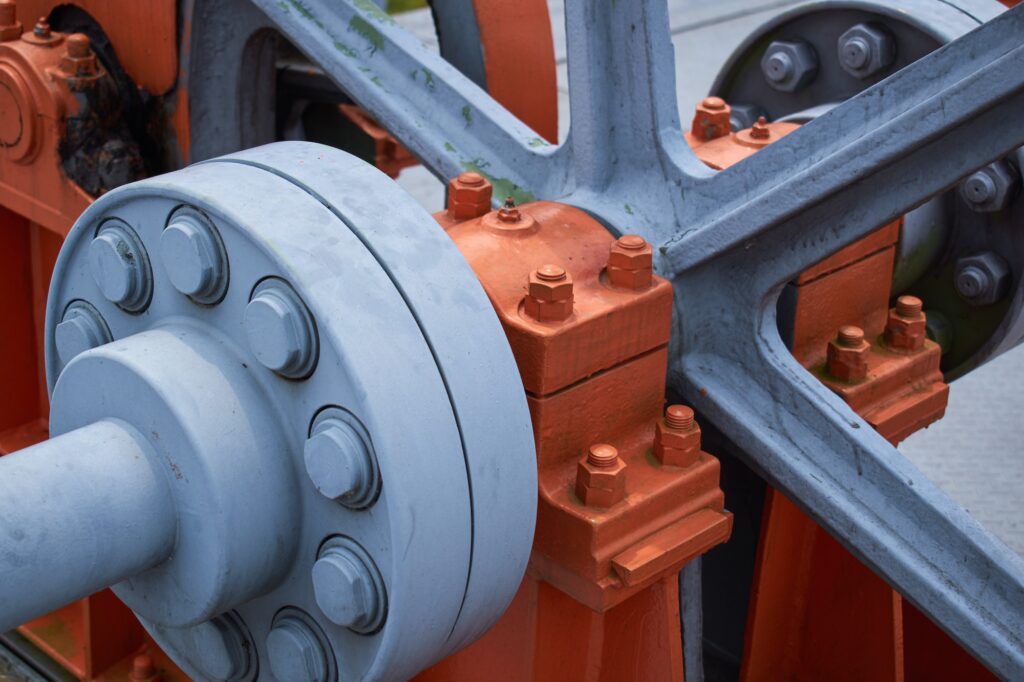

1. Consider Your Casting Requirements

When sourcing iron castings in China, it’s important to first consider your project requirements in terms of the size, shape, and weight of the casting you need.

You’ll also want to think about the desired surface finish and any special tolerances that need to be met.

Once you have a clear understanding of your project requirements, you can start evaluating potential suppliers.

There are also numerous types and grades of cast iron, and each has its own advantages and disadvantages.

For instance, gray iron casting is well suited for applications where high strength is not required but good machinability is needed, while ductile iron casting is ideal for applications that require high strength and impact resistance.

It’s important to know which type of iron is best suited for your project in order to select a supplier that can meet your material needs.

If you don’t know much about the types or grades, it doesn’t matter. You can also ask your supplier to provide a suitable solution for selection.

2. Do Your Research

When it comes to sourcing from China, the first step is always to do your research.

This means taking the time to learn about the Chinese market and understanding the unique challenges that come with doing business in China.

We recommend speaking to other buyers who have sourced from China in the past, as they will be able to give you first-hand insights into what to expect.

You should also consider retaining the services of a sourcing agent.

As they will have local knowledge and connections that will be invaluable in helping you navigate the Chinese market.

3. Evaluate Potential Suppliers Carefully

When sourcing iron castings in China, it’s important to take the time to evaluate potential suppliers carefully.

There are many fly-by-night operations in China that are looking to take advantage of unsuspecting buyers.

To avoid being scammed, make sure that you do your due diligence when vetting potential suppliers.

Check out online reviews, ask for references, and visit the supplier’s facility in person.

If at all possible, try to visit the foundry or factory before placing an order.

This will give you a chance to see firsthand how the operation runs and meet the people who will be working on your project.

Not only will this help put your mind at ease, but it also might give you some bargaining power when it comes time to negotiate pricing!

4. Check Whether the Supplier is Certified

The first thing you should look for when sourcing iron castings in China is experience.

You want to make sure that the supplier has experience in manufacturing cast iron parts, as this experience helps to ensure that they understand the quality standards that need to be met.

In addition, experienced suppliers are likely to have established relationships with other companies in the supply chain, which can help keep costs down.

The important thing to look for is certification.

Iron cating is a specialized process, so it’s important to work with suppliers that have been certified by the Chinese government.

China’s social and economic development has been so fast that environmental protection has been fully integrated into the national policy.

As a result, the number of factories that are harmful to the environment has decreased dramatically over the years.

A discharge permit is a basic requirement for operating a foundry.

If your potential foundry supplier is not equipped with this document, there is a risk of stopping production in the middle of the process, so you need to pay more attention.

Castimoo has 30 years of casting experience and is fully documented, stable operation, as a foreign buyer can feel safe to place orders.

5. Get Quotes from Multiple Suppliers

Once you’ve identified a few potential suppliers, the next step is to get quotes.

When requesting a quote, be sure to specify exactly what you need in terms of materials, dimensions, and quantity.

It’s also helpful to provide drawings or sketches so there’s no confusion about what you’re looking for.

Of course, it is totally possible for you to not provide any drawings and let the suppliers provide you with the appropriate solutions.

Castimoo is led by a professor from a local university specializing in casting, and a professional design and development team provides you with designs and solutions, as well as quotations.

Once you have the quotes in hand, it’s time to select the best option based on service, quality and price.

6. Negotiate

In China, negotiation is expected—so don’t be afraid to haggle a bit.

When it comes to iron castings, there are two main areas where you can try to negotiate: price and delivery time.

Regarding price, it’s important to remember that the quoted price is almost never the final price.

There’s always room for negotiation, so try to get the best price possible without jeopardizing the quality of the product.

As for delivery times, Chinese suppliers often underestimate the amount of time it takes them to produce an order.

Therefore, if a supplier promises you a particularly short delivery time that seems too good to be true, it is best to check with them for a daily, weekly production schedule or to work out a more realistic delivery date.

7. Place a Small Order First

Before placing an order, you will want to request a sample of the supplier’s work.

This will help you confirm that the supplier can meet your quality requirements.

Once you find a supplier that meets all of these standards, you can move forward with confidence knowing that you are working with a reputable company.

If everything goes well, place a small order with your chosen supplier before committing to a larger quantity or longer-term contract.

This will give you an opportunity to test-drive the supplier and make sure they meet your quality standards.

If everything goes well with your initial order, then you can proceed with confidence knowing that you’re working with a reputable supplier who can provide the products and services you need at a fair price.

8. Control Quality

Quality control (QC) is always important when sourcing manufacturing products, but it’s especially critical when sourcing from China.

This is because Chinese manufacturers have a reputation for producing products of varying quality.

So it’s important that you have systems and procedures in place to ensure that the goods you receive meet your standards.

By the way, if you are planning to visit a cast iron foundry or iron casting manufacturer in China, the following 3 points as important signs to judge whether a foundry is qualified or not for your reference.

1. Testing equipment

The composition inside the cast iron parts is related to the quality of the castings.

Therefore, whether the foundry is equipped with the appropriate testing equipment, such as hardness tester, metallograph, spectrometer, etc.

If the foundry has these main testing instruments, it means they have requirements for quality.

If even these instruments are not available, it is better to change one.

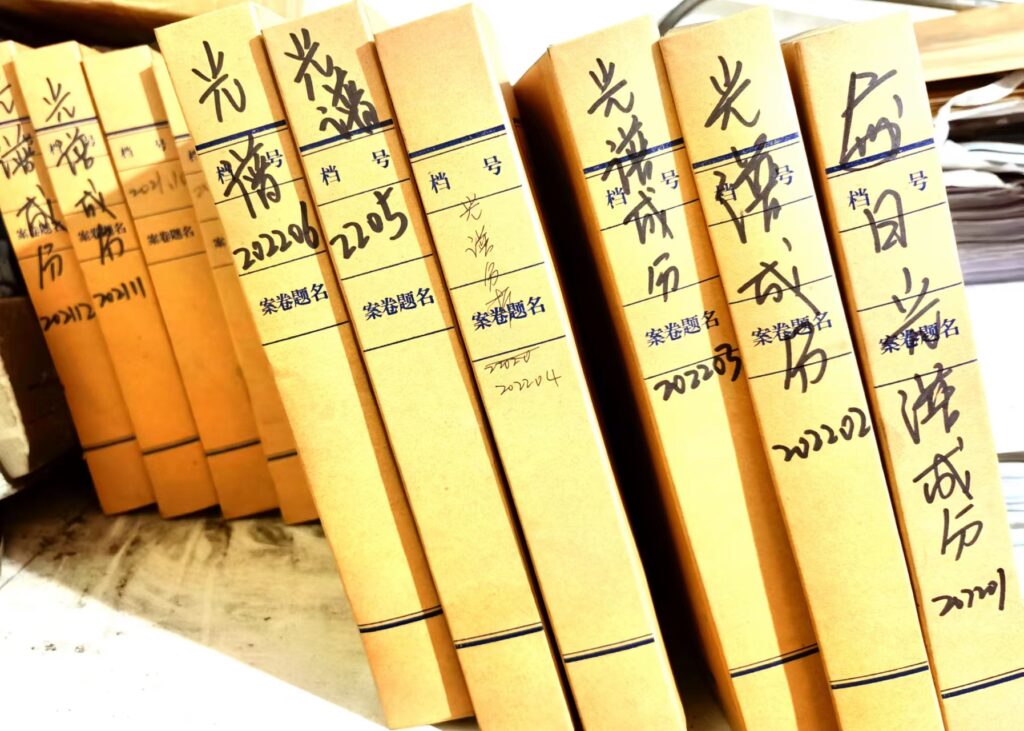

2. Quality management

Have these testing instruments is enough? Far from enough.

Are they serious in the use of these instruments? If it is just decorative, even the use of the method will not be, all in vain.

How to identify that they are using it?

For example, the spectrometer, first of all, to see whether it is always on.

Second, whether the composition is recorded.

Third, whether the records are available every day.

Especially the last point, some suppliers will bring you the data they have recorded, but then you have to pay attention that this does not mean they have records every day.

Therefore, you have to spot check.

Name a random time, like August 1 to take out the records and see. If they can’t get it out, that means the composition records are not being made every day.

3. Site organization

The third factor is whether the site is planned and organized.

For a foundry, it has to deal with molds, sand, and dust every day.

If they can plan the site clearly, it means that the foundry has the strength and ability to make production as much as they can master, at ease.

If the site is cluttered and disorganized, it will definitely affect productivity.

We recommend conducting thorough QC inspections at multiple stages of production, as well as performing final inspections before release of payment.

By taking these steps, you can minimize the risk of receiving subpar goods and having to deal with customer complaints down the line.

9. Be Wary of Intellectual Property Theft

It’s important to be aware of the risk of intellectual property theft when sourcing from China.

Unfortunately, intellectual property theft is fairly common in China, so it’s important to take steps to protect your intellectual property before entering into an agreement.

One way to do this is by signing a nondisclosure agreement (NDA) with your supplier—this will help ensure that they don’t steal your designs or technology.

10. Be Patient

Finally, it’s important to be patient.

Many Chinese suppliers operate on a “just in time” basis, so they may not have the product you’re looking for in stock at all times.

This means that your order may take longer to arrive than if you were sourcing from another country.

We recommend placing your order well in advance of when you need, or provide a quarterly or annual procurement plan to the supplier.

So that they can schedule production and make the appropriate amount of cast iron parts stock to ensure on-time shipments.

Conclusion

Casting is a popular manufacturing process for creating metal parts and products.

Iron castings are especially popular due to their low cost and high strength.

Sourcing iron castings in China can be a complex process, if you’re looking for tips on how to source iron castings in China, this blog post is for you!

We hope that these tips will help you save time and money on your next project.

Self-recommendation

If you’re looking for a reliable partner for your next iron casting project, look no further than Castimoo!

We specialize in gray iron and ductile iron castings, and can provide a one-stop service from mold design to finished product manufacturing.

Castimoo has 30 years of experience in the industry, so you can rest assured that we know our stuff.

And because we’re a one-stop shop, we can save you time and hassle in sourcing your casting needs from multiple suppliers.

We encourage you to get in touch with us today.