Introduction

When looking for a foundry, there are a few details that you need to pay attention to.

In this blog post, we will discuss the most important factors you need to consider when choosing a foundry. We will also provide some tips on how to evaluate a foundry and make sure it is the right fit for your business.

1. Is it a real foundry?

First, you want to make sure that the foundry you choose can provide you with the products you need. That means it is a foundry that produces castings, not other kinds of products.

For example, if you are examining a foundry, but the supplier is indeed a factory that makes sheet metal, it is not a match at all. It would be a waste of time to make an examination.

Besides, there are many types of castings, such as gray cast iron, ductile iron, white cast iron, malleable cast iron, peristaltic cast iron, etc. Different types require different production processes.

You need to confirm whether the foundry is good at making the product you need, and whether it has the process to make this product and can meet your needs.

2. Is there qualification?

Whether there is a business license, this is the most important prerequisite for you to work with this foundry.

Some small workshops are likely to be in the condition of unlicensed production, and such a workshop should definitely not be considered.

In addition, some countries are increasing their efforts to improve environmental protection, especially in China, and the penalties for factories that pollute the environment have been increasing in recent years.

Therefore, you also need to check whether the foundry has an environmental permit, or a discharge permit. This is not only to protect the environment, but also for your own products.

Because if the products are made in an unlicensed workshop, once they are found, they will probably be forced to stop production, which will cause trouble for your own business.

In addition, you need to find out if the foundry has obtained the ISO 9001 quality management system certification and if it has the relevant product certification.

This is very important because it can give you a guarantee of product quality.

3. How about the scale of production?

The scale of the foundry is also an important factor to consider.

A large-scale foundry usually has advanced production equipment and comprehensive quality control measures. They can provide you with high quality products and better after-sales service.

Even so, large-scale foundries have weaknesses. The biggest factor is price. Labor costs, overhead costs, equipment maintenance, etc. can all contribute to higher production costs.

Another factor is lead time. Large-scale foundries usually have a large number of orders and tight schedules.

Sometimes your order is very urgent and you need to deliver the product as soon as possible, but a large foundry may not be able to meet your short lead time needs.

On the other hand, small and medium-sized foundries are not as stable as large foundries in terms of production capacity and quality control, but they have their own advantages.

Small and medium-sized foundries are more flexible in production and can often meet your short lead time needs.

In addition, the prices of small and medium-sized foundries are usually more competitive than large foundries.

Therefore, when choosing a foundry, you need to find a balance between price, quality and lead time.

If your schedule is extremely tight, you may need to choose a small or medium-sized foundry that will provide you with a quicker response.

4. Does it pay attention to safety and security?

It is easy to overlook the importance of examining whether the foundry has taken appropriate safety measures to protect its workers.

These measures may include installing safety equipment, such as fire extinguishers and alarms, and having workers receive safety training, wear safety gear, etc.

Perhaps you think this is an internal management issue within the foundry itself and has nothing to do with me buying hands. Internal or external, that is a question.

First, if the foundry has safety equipment, it means that it is a formal, legal and compliant enterprise.

Second, the importance of safety protection also reflects that the owner of this enterprise cares more about loving employees, and attaches great importance to the life and safety of employees, and is an enterprise with humanistic care.

Third, if the employees’ safety awareness is enhanced, they can better protect themselves, which will also reduce the probability of product defects, improve the quality of products, and It is an efficient and highly competitive enterprise.

So when you visit the foundry, you must pay attention to whether the foundry has done the appropriate safety measures.

If the safety measures are not perfect, the foundry can be guided and explained accordingly, so that the foundry can raise awareness of safety and security.

5. How about the production environment?

When visiting a foundry, the production environment of the foundry is an important object to examine.

As a buyer you should look at the quality of the air, water and soil in the surrounding area, and how waste and emissions are managed, all with care for the environment.

Inside the foundry, if there is too much dust in the air, it not only affects the sight line and leads to lower quality of product production, but also causes pollution to the lungs and other respiratory diseases.

Therefore whether there are reasonable exhaust channels, this is something to look out for.

In addition, for a foundry, it has to deal with molds, frames, sand molds and blanks every day.

If they can plan the site clearly, it means that the foundry has the strength and ability to make the production as much as possible and at ease.

If the site is cluttered and disorganized, it will definitely affect the production efficiency.

6. How to control the quality of products?

I bet that whoever it is, will not want to buy products with questionable quality. Cast iron parts are more quality first.

Especially how to control the composition, whether the ductile iron is spheroidal, whether the hardness is up to standard, etc., these are the points that need attention.

The internal composition structure of cast iron parts is closely related to the quality of castings.

If the foundry is equipped with corresponding testing equipment, such as spectrometer, metallograph, hardness tester, etc., it means that they have requirements on quality.

If even these basic measuring instruments are not available, and all rely on the staff’s feeling to operate, it is recommended that it is better to change one.

Is it enough to have these testing instruments? Far from enough.

Quality control personnel are using these instruments every day? If the instrument is just for show, and even the use of the method will not be, all in vain.

How to identify these instruments have in use?

For example, the spectrometer, first, to see whether it is always on; second, to see whether the composition of the records; finally, to see whether these records are available every day.

Especially the last point, some foundries will give you their recorded data, but at this point you have to be aware that this does not mean that they have records every day.

Therefore, you must perform spot checks. Specify a random time, for example, “Please show me the records for November 8”. If they can’t bring it out, it means they don’t have records every day.

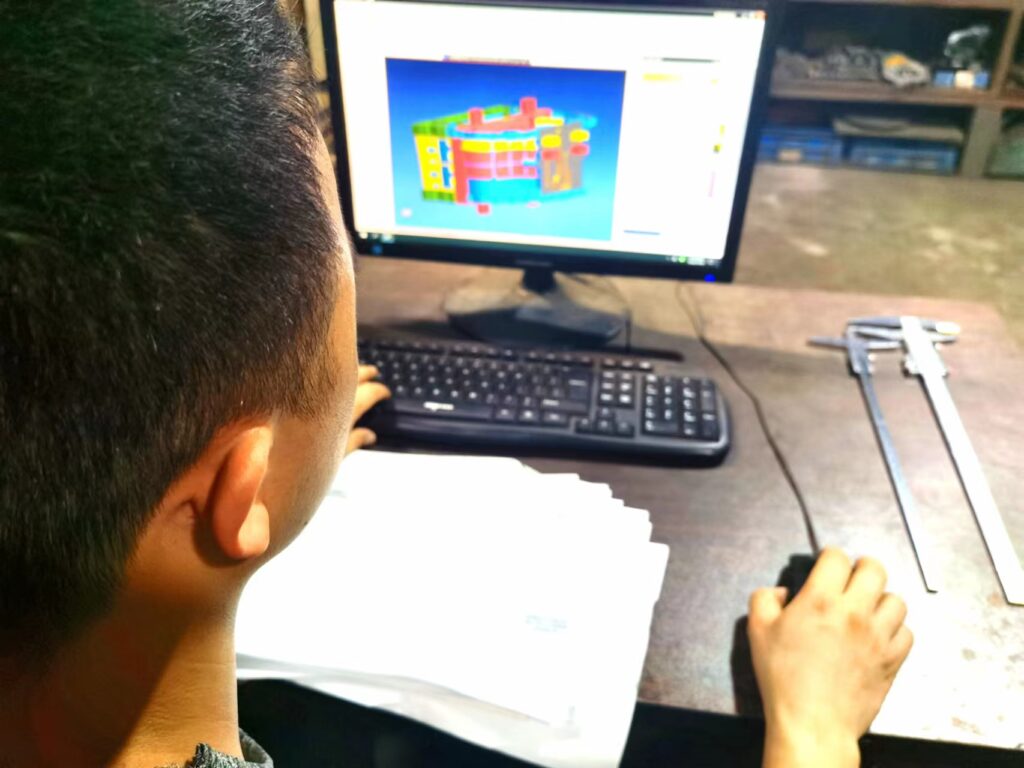

7. Can they design molds?

When visiting a foundry, the buyer needs to make sure that the mold design is appropriate for the type of casting to be done.

The design should also be suitable for the size and shape of the part to be cast.

If the mold is poorly designed, the location, size and shape of the gate and riser are not reasonable, which can lead to major defects in the casting.

Therefore, the presence of a professional design department is also a key point to be examined when examining.

If necessary, you can let the designer live operation demonstration once the 3D design process.

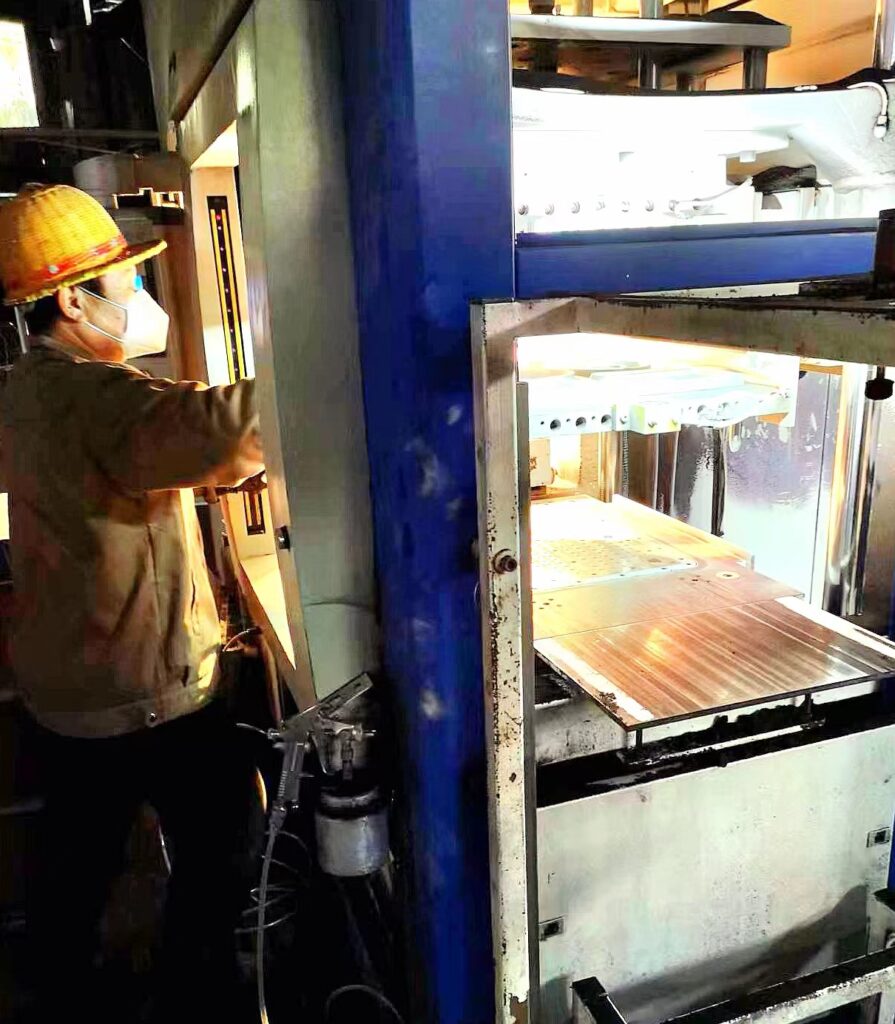

8. Whether to use automatic molding machine?

For small pieces of castings, the use of automatic molding machine to model is the most efficient choice.

Compared with manual molding, automatic molding machine not only high efficiency, but also more tightly pressed, producing better casting results.

Therefore, when examining a foundry, it is also important to evaluate the foundry equipment.

Depending on the needs of the buyer, a foundry with an automatic molding machine can guarantee capacity without fear of not being able to deliver on time if the castings needed are small and in large quantities.

In addition, it is important to consider the age of the equipment when evaluating a foundry’s equipment.

If a foundry uses very old and outdated equipment, this can also affect the quality of its castings.

Therefore, when examining equipment, it is important to ask about the age of the foundry’s equipment.

9. Is it capable of mechanical processing?

If you just need to purchase iron casting blanks, the foundry is able to do it.

But if you need further mechanical processing, pay attention to how the foundry is doing in terms of mechanical processing.

Foundry without mechanical processing area, need to outsource the processing of this piece to another processing plant, the invisible cost will increase.

It is recommended that the buyer choose a foundry with mechanical processing support, not only to save costs, and problems in processing can be found immediately and solved in a timely manner.

When examining the machining workshop, do not forget to assess the processing equipment, capacity, process, quality control and other aspects.

10. How is the quality of the responsible person?

This is the last point of the examination of the foundry, but also the most important factor. The responsible person here refers to the manager.

The quality includes whether they have a good idea of the technology of the product, whether they are willing to consider the buyer and cooperate fully to facilitate collaboration.

For example, the experience and ability to adjust the composition structure for a specific type of casting; the willingness to spend time and cost to conduct tests for completely new requirements; and the willingness to be able to actively cooperate in the face of the buyer’s customer’s needs and problems.

All these can be felt in the conversation with the responsible person, from their words and actions.

The quality of the person in charge is also the most important factor in assessing the success of future cooperation.

Conclusion

To sum up, this article summarizes the details to keep in mind when examining a foundry.

They are whether it is a foundry, whether it is qualified, what is the scale of production, whether it pays attention to safety and security, how is the production environment, how the quality of the product is controlled, whether it can design molds, whether it uses automatic molding machines, whether it can do mechanical processing, and what is the quality of the person responsible, in ten areas.

Castimoo is a medium-sized iron casting manufacturer with 30 years of experience in the production of gray and ductile iron.

The comprehensive production and quality control facilities are able to guarantee high quality products and deal with customers’ short lead time delivery needs.

The design team is led by professors of university casting majors, and the mold is designed with reasonable gating system, and the product quality is well received by domestic and foreign customers.

I hope this article can bring you some suggestions when you are examining the foundry.

We also hope that you can contact us if you need to purchase iron castings, and we will provide you with the best quality products and services.

2 Responses