Introduction

If you are looking for a new career, then you may want to consider becoming a foundry worker. If you are in the process of selecting a qualified foundry to provide quality iron casting products for your project, then it is even more important that you understand the basic abilities that foundry workers possess in order to make a comprehensive assessment.

Foundry workers are responsible for the fabrication of iron castings. They must have a variety of basic abilities in order to do their jobs effectively. In this blog post, we will discuss the 10 most important abilities that foundry workers need to have.

1. Casting knowledge

Casting is a highly technical industry. Although it appears that the process is relatively simple and even people who are not casting professionals are able to make iron castings, the quality varies and is even far from each other.

Casting workers must have a thorough understanding of casting, metallurgical science and the reactions of different metals under different conditions. This includes an understanding of the composition of cast iron, casting temperatures, pressures and other factors that affect the properties of the metal.

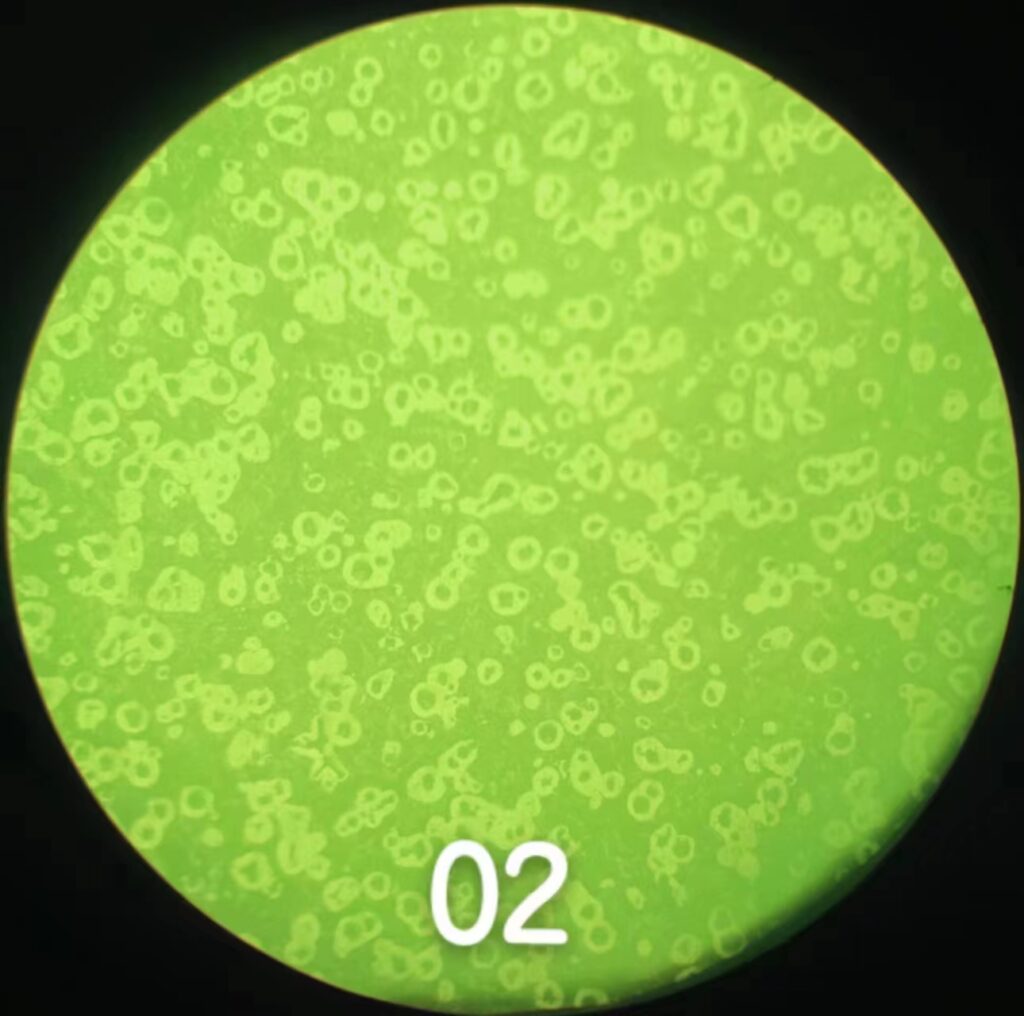

In order to ensure the quality of cast iron, metallography must be observed and composition determined, and this is where casting expertise plays an important role.

Knowledge of the effects of heat treatment and shaping processes on the material is required, and the ability to identify the various types of alloys and how they respond to different conditions. Understanding the properties of various alloys is critical, as it allows workers to select the right alloy for the job and ensure that the parts produced meet the customer’s needs.

If workers do not understand how a certain alloy behaves under certain conditions, they will not be able to produce the part they need. This can lead to damaged or ruined parts, as well as costly production delays.

2. Safety knowledge

Casting is a somewhat hazardous job. Foundry workers must be able to identify and avoid potential safety hazards in their work environment, which means they must be aware of the risks of heat, fumes, dust and noise.

In a foundry, the equipment used to melt and process metal generates heat. If not handled properly, heat can lead to burns and other injuries. Foundry workers should wear protective clothing such as long pants, long sleeves, gloves, safety glasses, hard hats and, if necessary, respirators. They must also make sure to stay away from hot surfaces and not touch any equipment until it has cooled.

Fumes are produced when metal is heated and may cause respiratory problems and dizziness. Casting workers should ensure that the area is adequately ventilated or wear a respirator if necessary.

Dust from the foundry process can also irritate the eyes, nose and throat, so it is important to wear protective equipment, including face masks and dust masks.

Noise levels in the foundry environment can also be high, which can cause hearing damage if not properly protected. Workers should wear earplugs or other hearing protection when working in a foundry.

In addition to being aware of these safety hazards, it is important to follow safety protocols such as always wearing proper protective clothing and paying close attention to hot surfaces. By following these procedures, foundry workers can stay safe and healthy on the job.

Following safety measures is as important to a successful casting operation as it is to the health and well-being of workers.

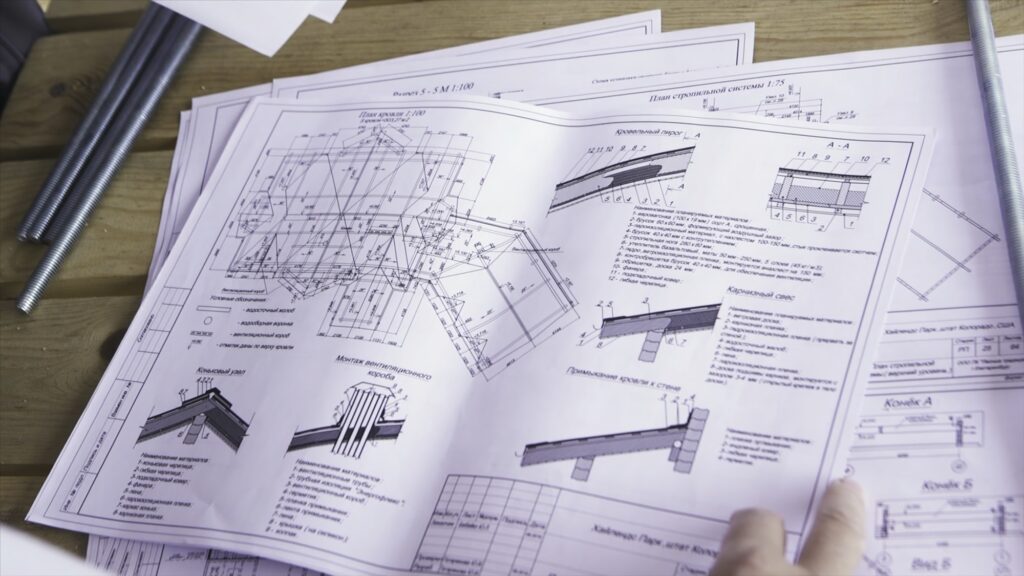

3. Ability to read technical drawings

Foundry workers must have the ability to read and interpret technical drawings and correctly translate them into manufactured parts. This involves the ability to read dimensions, tolerances and other details on drawings. It requires a careful eye for detail and an understanding of how the different parts fit together.

Casting workers must be able to make educated guesses about partial details when there is not enough information on the technical drawings. This means they need to have a good understanding of the parts they are casting and their purpose.

But it’s not just technical knowledge that makes a good caster; they also need to have an aesthetic eye. The ability to make a first reasonable design for the customer while also being able to make sound suggestions when there is something inappropriate in the customer’s drawing. This requires creativity and a good understanding of how the part will look when it is finished.

Therefore a qualified foundry worker, understanding technical drawings is only part of the equation, creativity and attention to detail are also important components that cannot be ignored.

4. Knowledge of mold design and fabrication

Designing a mold is an indispensable step for casting, which is a prerequisite for designing a reasonable mold. Therefore, to be a good foundry worker, one must first understand and master mold design.

This requires learning the basics of designing a mold, understanding the various surface treatments, and the different types of materials that can be used to make a mold.

Mold making involves many steps and precise measurements. From cutting and forming mold parts to welding and polishing, one must be able to handle these steps in order to produce a quality product. In addition, knowledge of several tools that must be used to make molds, such as mills, lathes, grinders, saws and other machine tools, is necessary.

Having a deep understanding of mold design and manufacturing is essential for foundry workers. It is a skill that can be honed through practice and if done well, will bring a level of excellence to the products they produce. With knowledge of mold design and fabrication, foundry workers can create molds that are both reliable and aesthetically pleasing.

5. Ability to work in extreme temperatures

Foundry workers are constantly dealing with molten metal and must be able to endure the heat of the environment without injury and still perform their duties effectively. After all, no one wants a worker who is about to pass out from overheating.

Advanced foundry workers must also understand how to pour molten metal into a mold without compromising its integrity. In other words, they need to be able to determine the best way to put the metal in without burning themselves.

This may not sound like a problem, but it’s not as easy as it seems. Foundry workers must understand the entire process and be experienced enough to pour metal safely and accurately – which often means handling metal at temperatures of 1,500 degrees Celsius or higher.

6. Machining and fabrication skills

Foundry workers must be able to use a variety of power tools and hand machines in order to cut, shape, form and assemble metal parts in the casting process.

Foundries often require the use of both manual and CNC machines. With manual machines, workers must have a good eye for detail to create accurate parts that meet customer specifications. CNC machines are highly automated and require operators to understand programming languages such as G-code and CAD/CAM software.

The fabricator must understand the forming process, such as rolling. This involves selecting the correct tooling and setting up the machine to create parts that meet specified tolerances. They must also know how to properly heat treat metal parts to change their properties to make them suitable for various applications.

All in all, a good understanding of machining and fabrication is essential for any foundry.

7. Welding Skills

Foundry workers need to have an understanding of the welding process in order to complete the casting job. Welding is an important skill that allows the welder to join two metals together and create a strong, durable connection. It is also necessary for repairs or modifications that may be required during the casting process.

The two most common types of welding used in foundries are oxy-acetylene and electric arc welding. Oxy-Acetylene is a process that uses oxygen and an acetylene flame to produce extremely high temperatures that can be used to join metal parts together. This type of welding is ideal for small, complex jobs where precision is critical.

Arc welding is a process that uses electricity to create an electric arc between two metals, which generates enough heat to join them together. This type of welding is often used for large jobs where speed and efficiency are important.

Regardless of the type of welding that needs to be done, foundry workers must have the following knowledge and skills:

– Understand how welding works, including the different types of welds and what they are used for.

– Knowledge of safety precautions for working at high voltages.

– Have the ability to read drawings and schematics detailing the specifications of a welding job.

– Know how to set up a welding machine and adjust it to meet requirements.

– Have the ability to properly inspect welds for quality and integrity.

A good understanding of welding is essential for the foundry worker in order to perform the job safely and successfully.

8. Ability to use measuring tools

Foundry workers must be able to accurately measure and inspect cast parts. Failure to have a keen eye for and proper application of measuring tools leads to inaccurate casting dimensions and trouble for the customer.

For example, if a casting requires specific dimensions that meet industry standards, it is the responsibility of the foundry worker to ensure that these specifications are met by using the correct tools. This may include calipers, gauges, or even microscopes for measuring very small features.

The importance of accuracy when measuring casting parts cannot be overemphasized. A small miscalculation or a less-than-accurate tool can quickly lead to costly errors and wasted time. Having the right measuring tools and experienced staff is critical for any foundry that wants to consistently produce high quality castings.

9. Problem solving ability

Foundry workers need the ability to solve any problem that arises during the casting process and to develop creative solutions quickly and effectively. The success of a casting job often depends on this.

But problem solving isn’t just about fixing broken machines or finding solutions to design challenges. It also involves being able to think holistically and anticipate potential problems before they arise. The best foundry workers know that the most effective way to handle any situation is to be prepared.

This means having the mental agility to quickly assess a situation and come up with an effective solution. It also involves staying organized and having the discipline to follow through with solutions once they are implemented.

10. Communication skills

Foundry Workers must be able to communicate effectively with their supervisors and other team members to ensure that each job moves forward smoothly. Communication skills help ensure that safety protocols are followed and that each job is completed on time and within schedule.

Good communication also helps foundry workers understand the specific instructions they need to follow, which can reduce errors and increase productivity. In addition, having strong communication skills allows foundry workers to seek guidance when needed or to respond quickly to any changes.

It is also important for foundry workers to have good verbal and written communication skills when interacting with co-workers or customers. This helps to ensure that customers receive accurate feedback on their orders and that any questions they may have are answered quickly and professionally.

Communication skills also help foster a positive team dynamic and help all team members understand the importance of working together on every job.

Ultimately, strong communication skills are essential for foundry workers, who often work in high-pressure situations and must be prepared to make adjustments on the fly. Having good communication skills can help ensure that all tasks are completed accurately and quickly, leading to better results for customers and a more successful business.

Conclusion

In this article we have summarized 10 basic abilities that you should have as a foundry worker. It includes having knowledge of casting, safety, the ability to read technical drawings, knowledge of mold design and fabrication, the ability to work in extreme temperatures, machining and fabrication skills, welding skills, the ability to use measuring tools, problem solving skills, and communication skills.

If you have these abilities, then a career as a foundry worker may be the best fit for you. If you are planning to look into a foundry, a foundry worker with these abilities can be very profitable for you.

We are Castimoo, an iron casting supplier. Specializing in ductile iron and gray cast iron with over 30 years of experience. Our foundry workers have 10 or even almost 20 years of experience in production and machining, and can provide you with the safest and most efficient service. Our products are favored by customers all over the world, and we hope that our services will also bring you considerable profits. Welcome to contact us at any time.